Method for detecting relative angle of small circular hole of revolving body thin-walled part

A thin-walled parts, relative angle technology, applied in the field of parts inspection, can solve the problems of small angle, slow process, large error and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

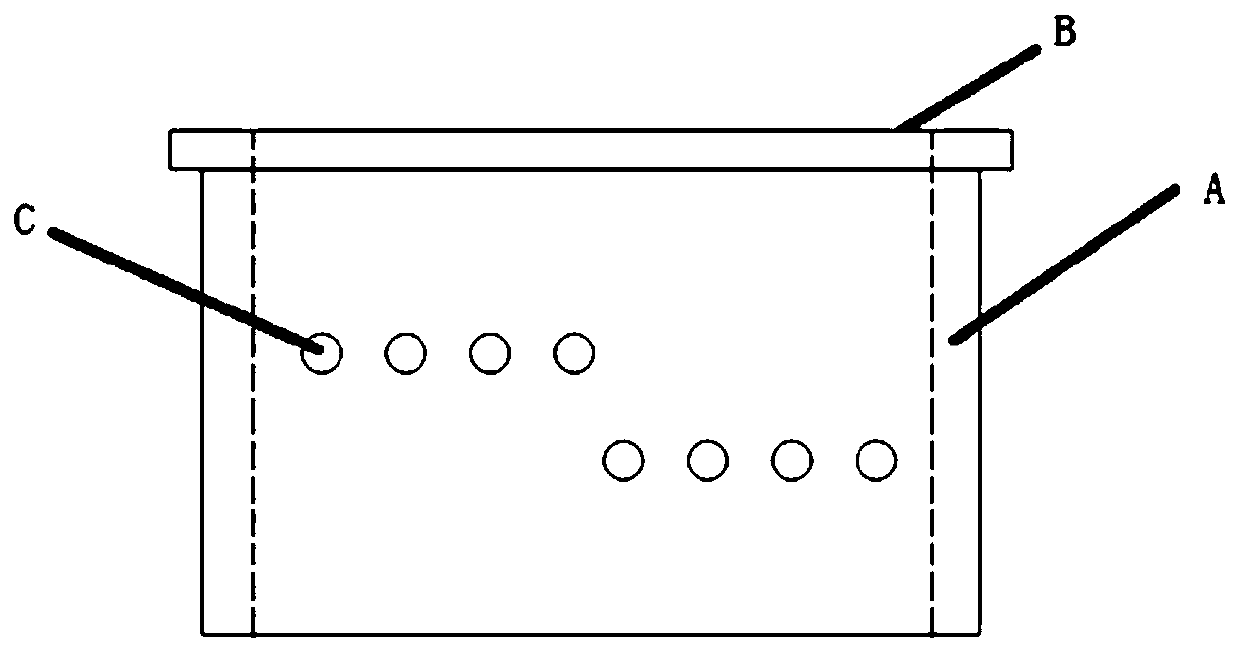

[0046] like figure 2 As shown, the clutch bushing is taken as an example, the wall thickness is 3mm, and the outer ring of the bushing is divided into upper and lower layers in the radial direction, and a total of 8 small holes with a diameter of D4mm are processed. The angle between adjacent holes is small and the tolerance requirements are strict.

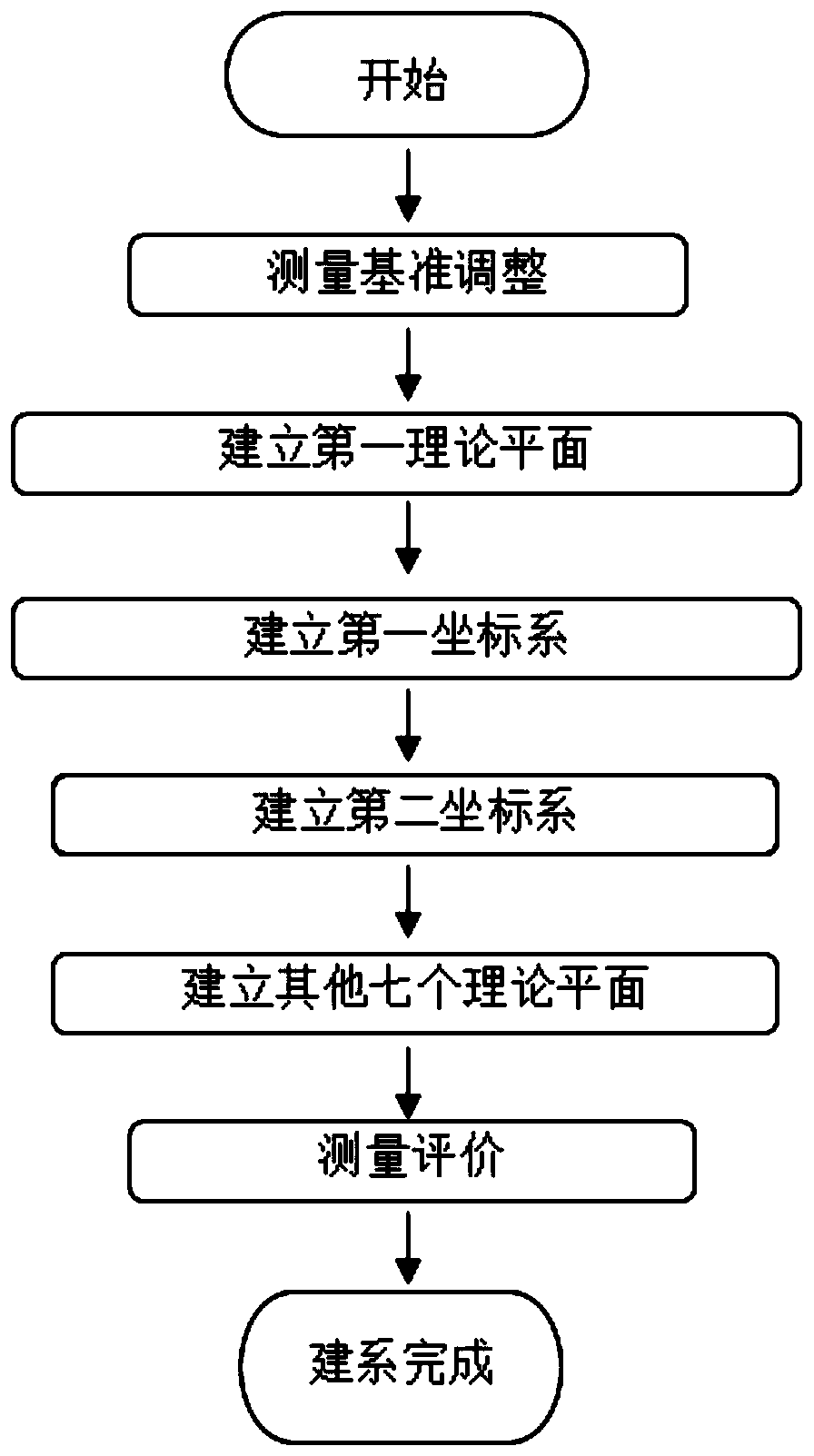

[0047] A method for detecting the relative angle of a small circular hole in a thin-walled part of a rotating body, comprising the following steps:

[0048] The first step is to adjust the measurement benchmark:

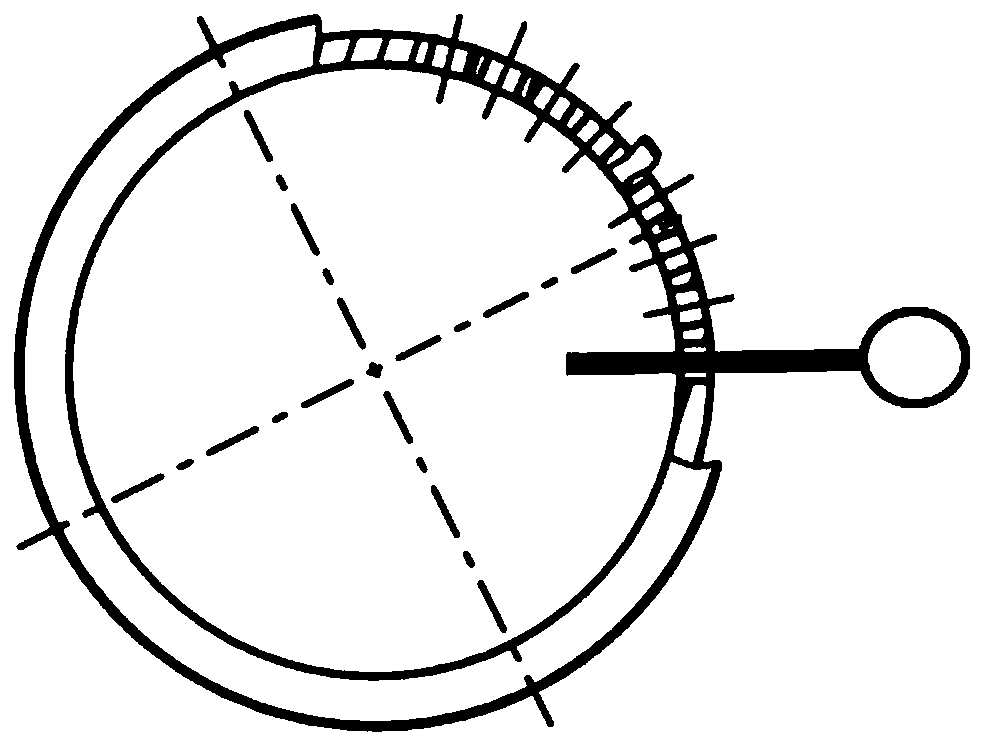

[0049] The thin-walled parts of the rotating body are placed on the measuring table so that the axis of rotation of the thin-walled parts of the rotating body, that is, the central axis of the reference cylinder A, is placed perpendicular to the XY plane of the measuring table. First, make the measuring rod and the X-axis direction of the measuring equipment consistent, such as figure 2 , image 3 As shown, adjust th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com