Rapid cable wiring device for electric power overhaul

A technology for power maintenance and wiring devices, which is applied to the parts of the connecting device, coupling devices, circuits, etc., can solve the problems of being squeezed into the hands of the operator, low operating efficiency, and reduced practicability, so as to reduce potential safety hazards, Simple operation and improved practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

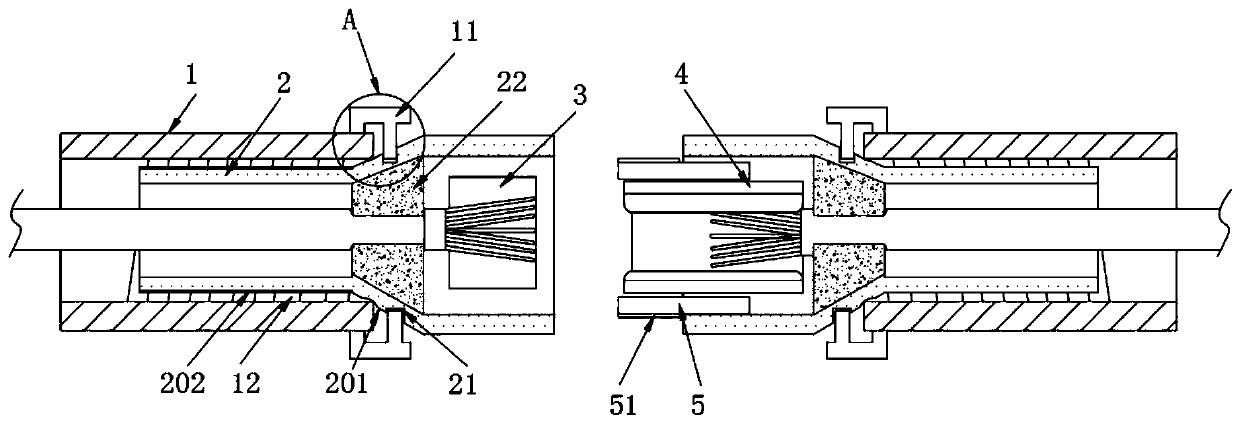

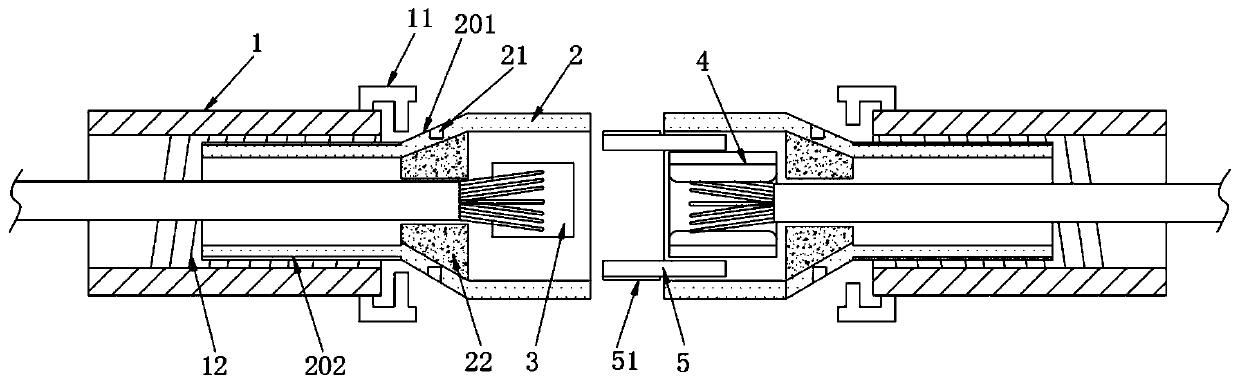

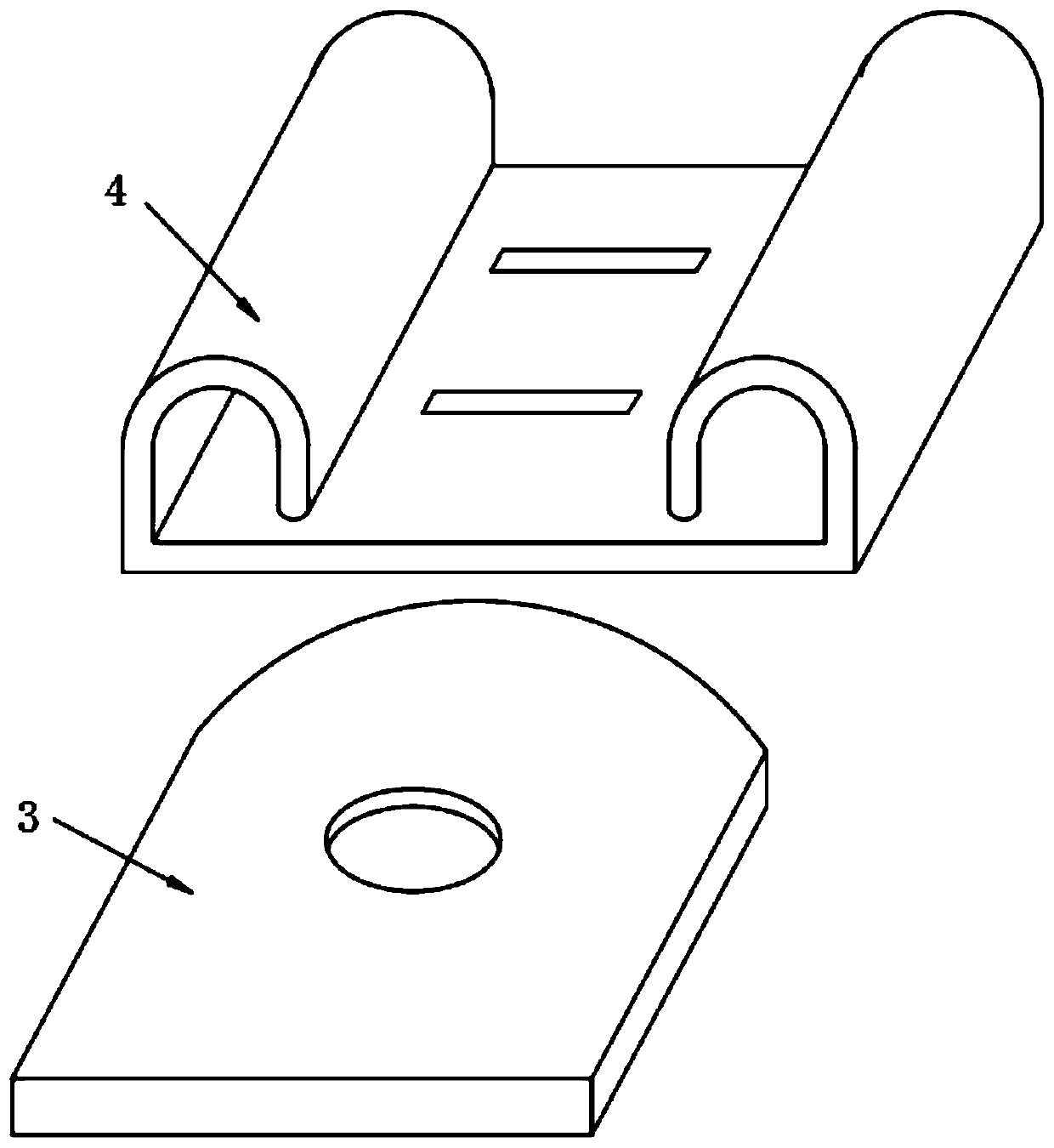

[0019] see Figure 1~4 , in an embodiment of the present invention, a cable quick connection device for electric power maintenance, including a clamping shell 1, the number of clamping shells 1 is two, and the outer wall of the clamping shell 1 is fixedly connected with two symmetrically distributed limiting blocks 11, two The terminal block 2 is screwed and fixed inside the clamping shell 1, and the outer wall of the terminal block 2 is provided with two limit card slots 21 that match the limit block 11, and the two limit card slots 21 are engaged and fixed on the two sides respectively. Inside the limit block 11, the inner wall of the terminal block 2 is fixedly connected with two extrusion clips 22 which are symmetrically distributed, one of the terminal blocks 2 is fixedly connected with the sub-terminal insert spring contact piece 3, and the other is connected with the terminal block 2. The inside of the end base 2 is fixedly connected with the female end spring contact p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com