Slaughtering equipment for animal husbandry

A kind of equipment and box technology, applied in the direction of slaughtering, livestock slaughtering table/slaughtering support, slaughtering device, etc., can solve the problems of low efficiency, animal fixation, and difficult slaughtering process, and achieve great application prospects, simple and reasonable structure, Improving the effect of fixed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

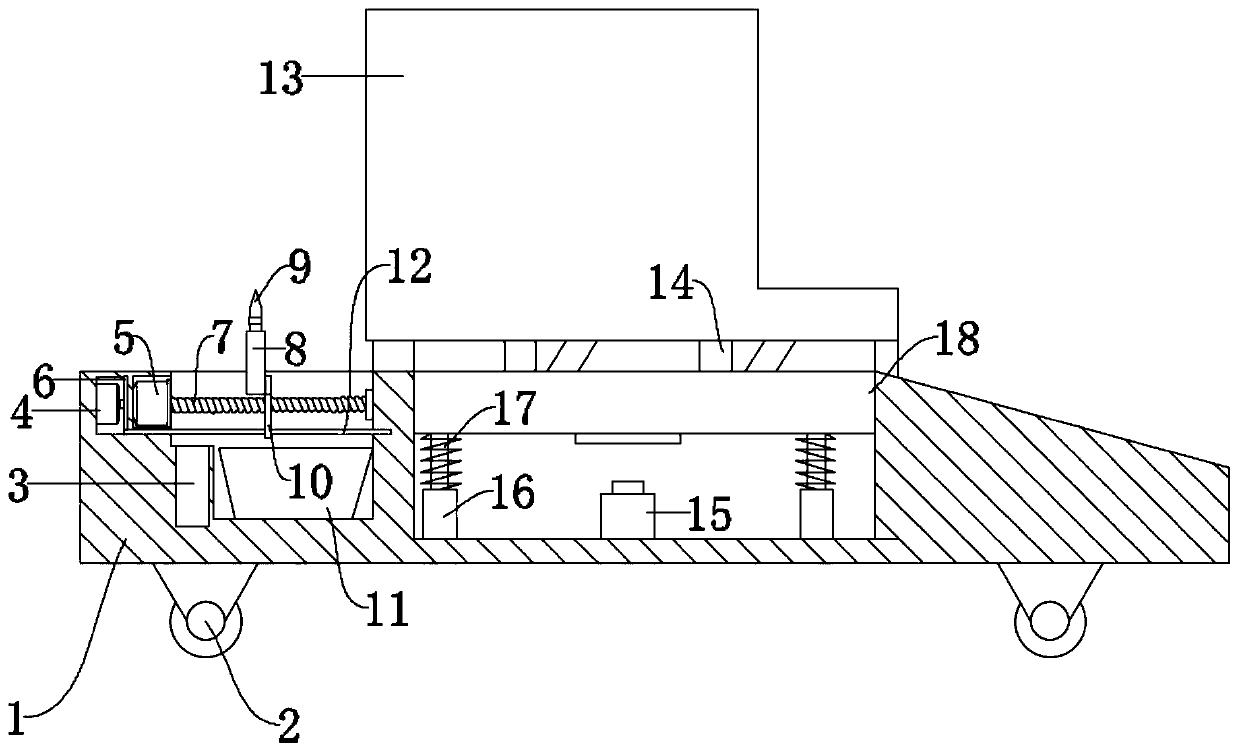

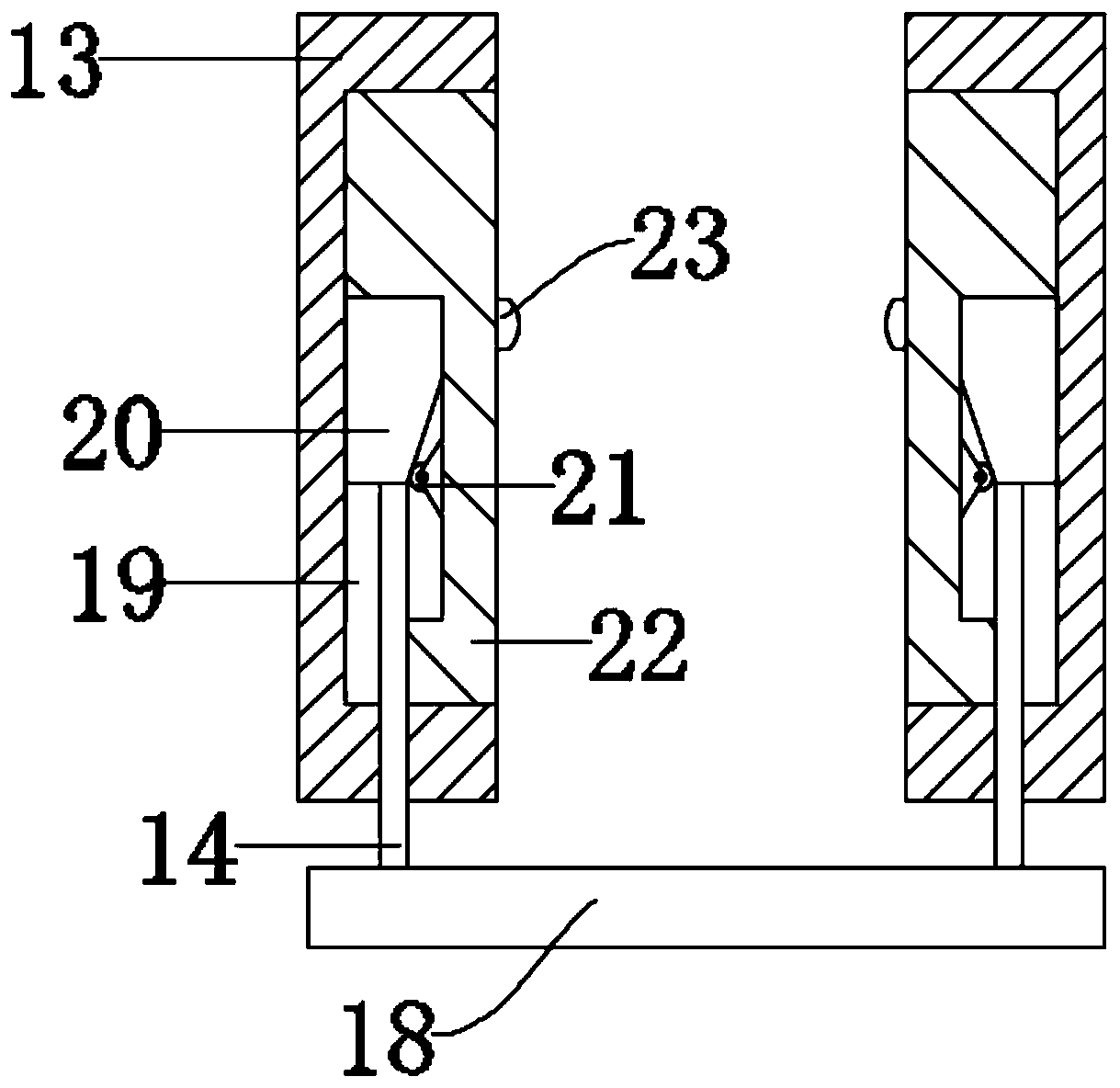

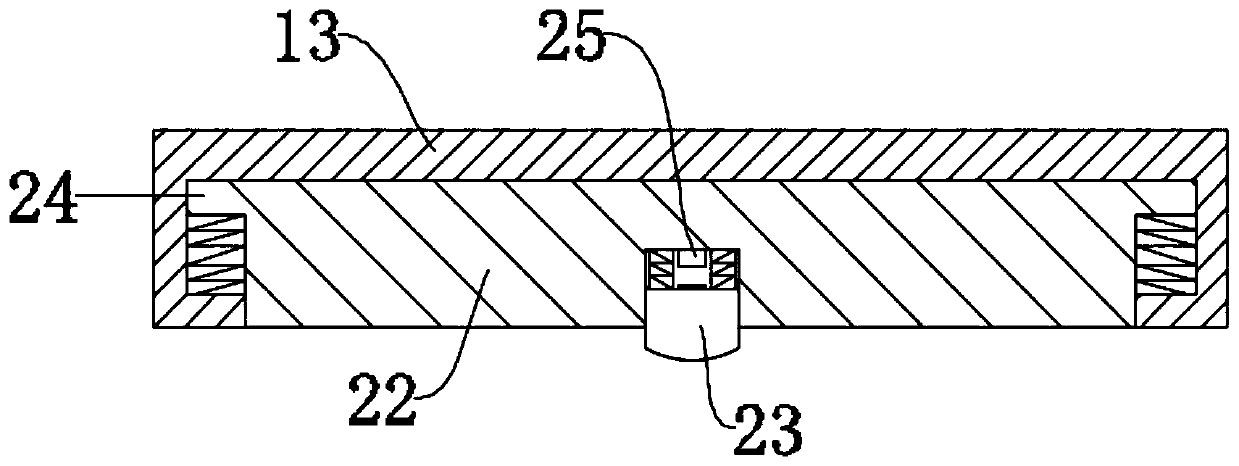

[0024] see Figure 1-6 , a kind of slaughtering equipment for animal husbandry, including a box body 1, one end of the box body 1 is arranged obliquely, and then it is convenient for livestock to board the box body 1, and a fixing component, a slaughtering component and a disinfection component are arranged on the box body 1, and the described The fixed assembly fixes the livestock on the box body; the fixed assembly includes a side plate 13, an extrusion block 22, a carrier plate 18 and a connecting rod 14, and the side plate 13 is fixedly connected to both sides of the box body 1, and the side plate 13 is provided with a placement groove 19, and the extrusion block 22 is slidably arranged on the placement groove 19, and the driving wheel 21 is rotated on the extrusion block 22. Between the extrusion block 22 and the side plate 13 The driving block 20 is slidingly arranged, and the driving block 20 acts on the driving wheel 21. The bottom of the driving block 20 is fixedly co...

Embodiment 2

[0032] In order to further improve the actual use effect of this device, this implementation has made the following improvements on the basis of Embodiment 1. The improvement is that the bottom plate of the box body 1 is rotatably equipped with a roller 2 with a brake function. Described roller 2 further improves that this device is easy to move, improves actual use effect.

[0033] The working principle of this embodiment: by installing rollers 2 on the bottom plate of the box body 1, the device is further improved to be easy to move, and the actual use effect is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com