An automatic metering glue injection device

A glue injection device and automatic metering technology, applied in the glue injection field, can solve the problems of high cost and low production efficiency, and achieve the effect of reducing the number of people, reducing the work intensity and realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

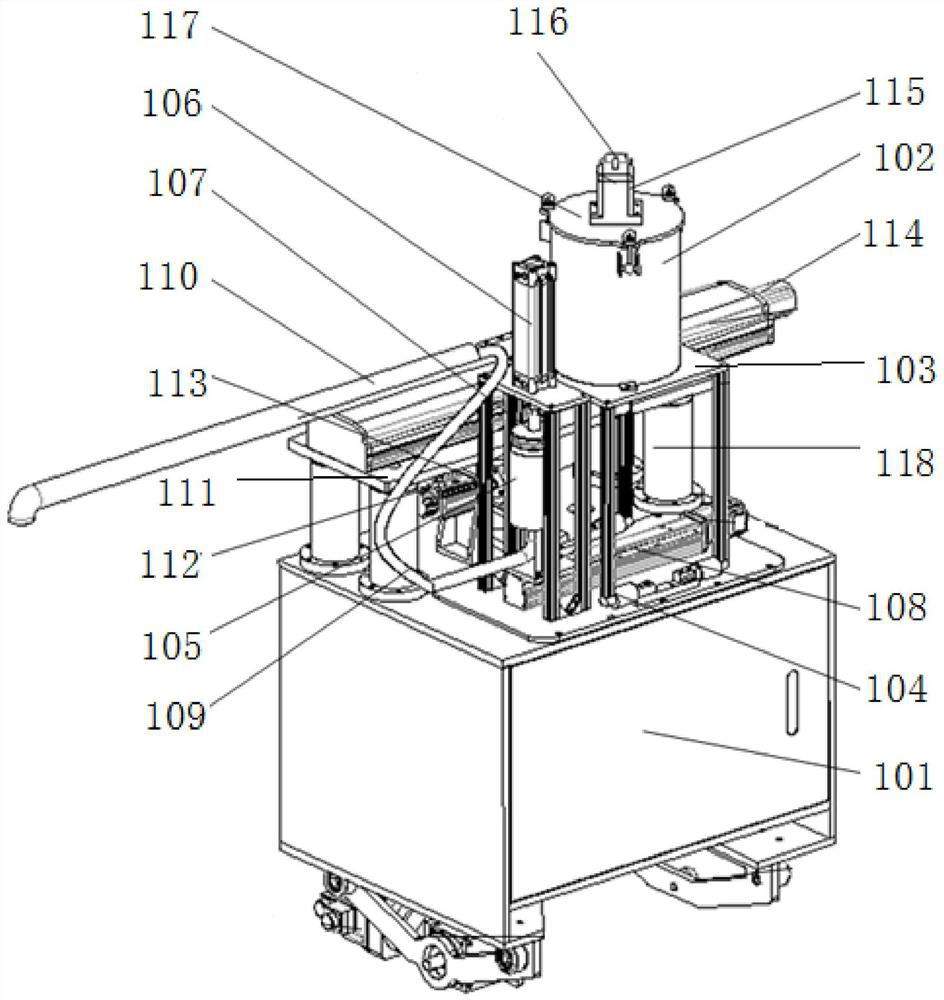

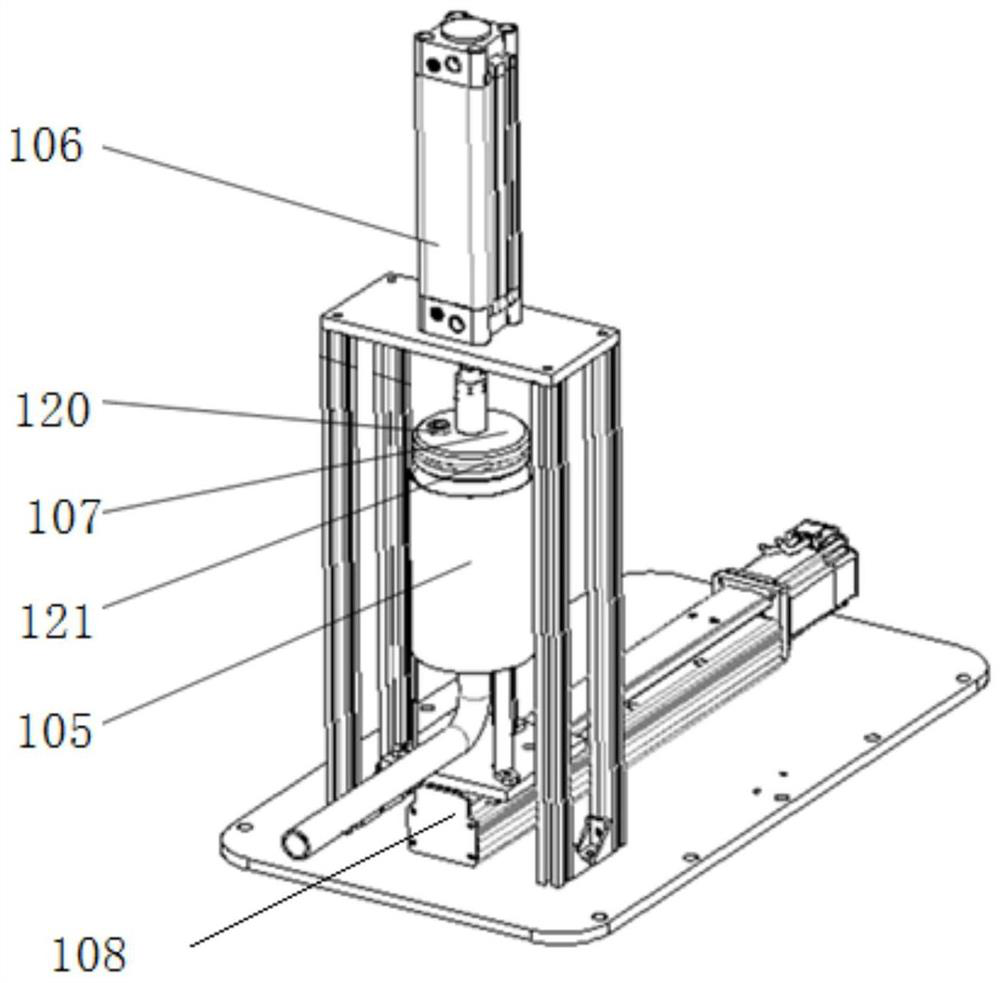

[0027] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] The invention provides an automatic metering glue coating system, which is suitable for the coating of high-viscosity rubber materials. The system adopts computer remote control, no one intervenes in the production process, and automatic metering and feeding, glue injection, scraping, and centrifugal rotary glue are all realized. Production automation is achieved, and production data is collected and stored in real time during the entire production process, realizing the informatization of the production process.

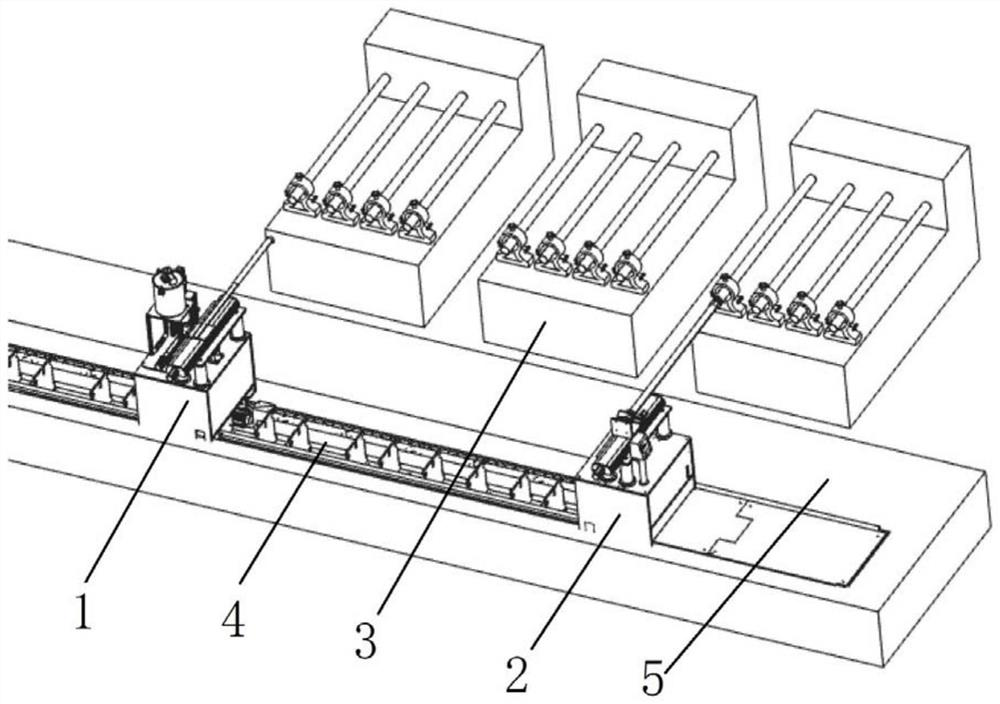

[0029] Such as figure 1 As shown, the automatic metering glue application system of the present invention includes an automatic metering glue injection device 1 , an automatic material pulling and scraping device 2 , a ground rail walking device 4 and three sets of centrifugal rotating glue devices 3 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com