Paper gift bag cutting device

A gift bag and paper technology, which is applied in the field of paper gift bag interception devices, can solve the problems such as the position of the opening hole is not centered, the efficiency of opening the hand hole is low, etc., and the effect of high interception efficiency is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

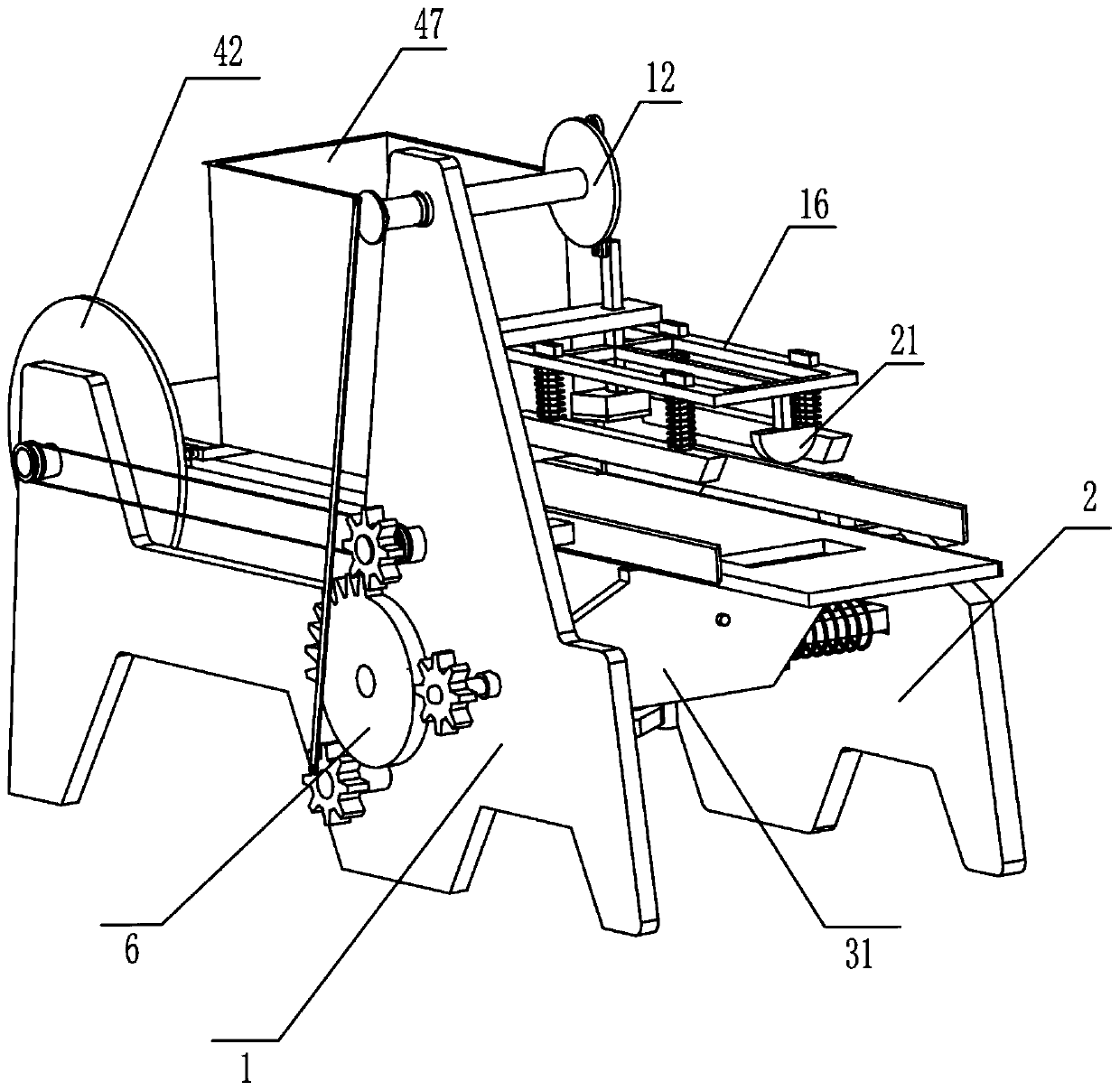

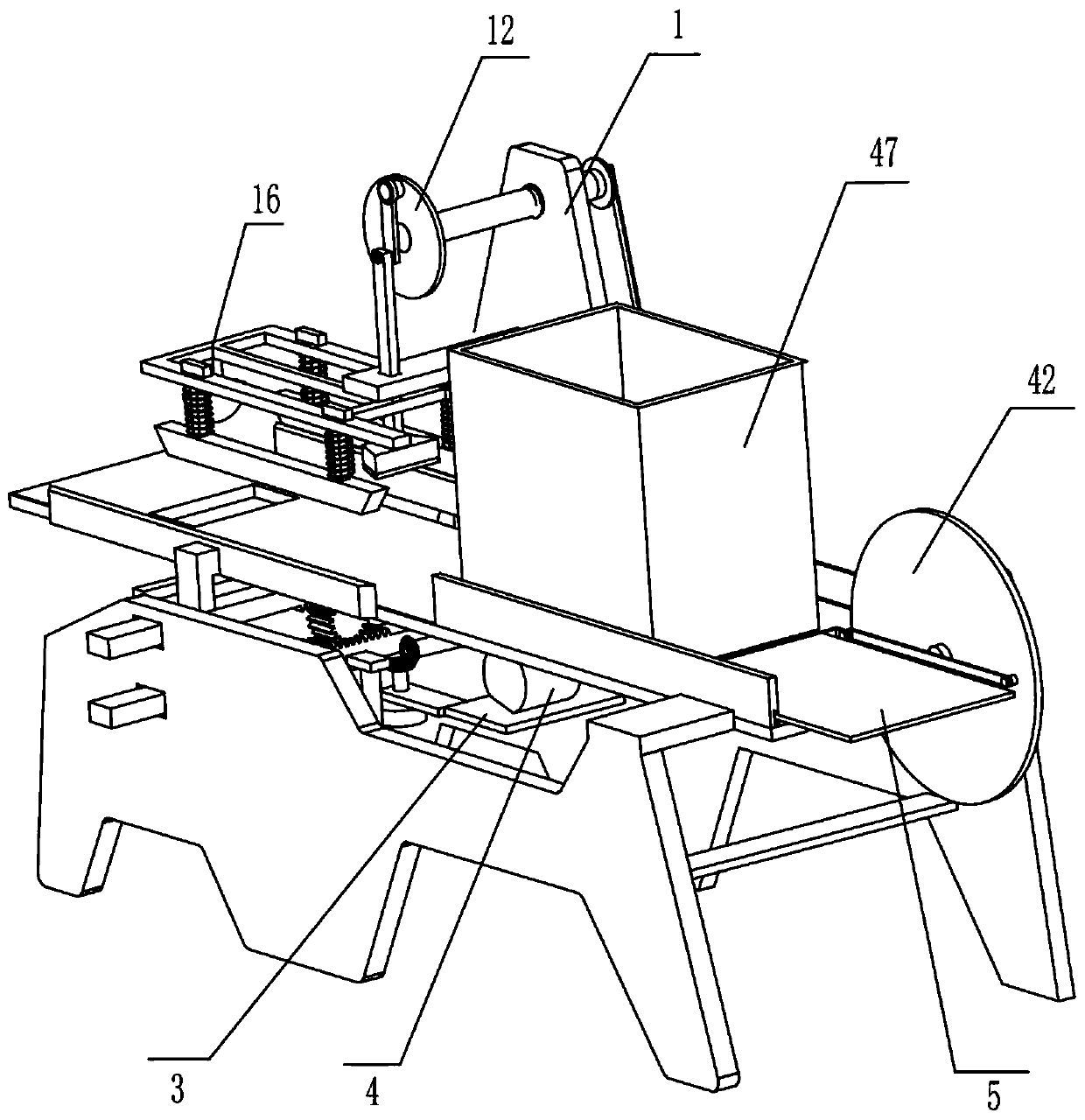

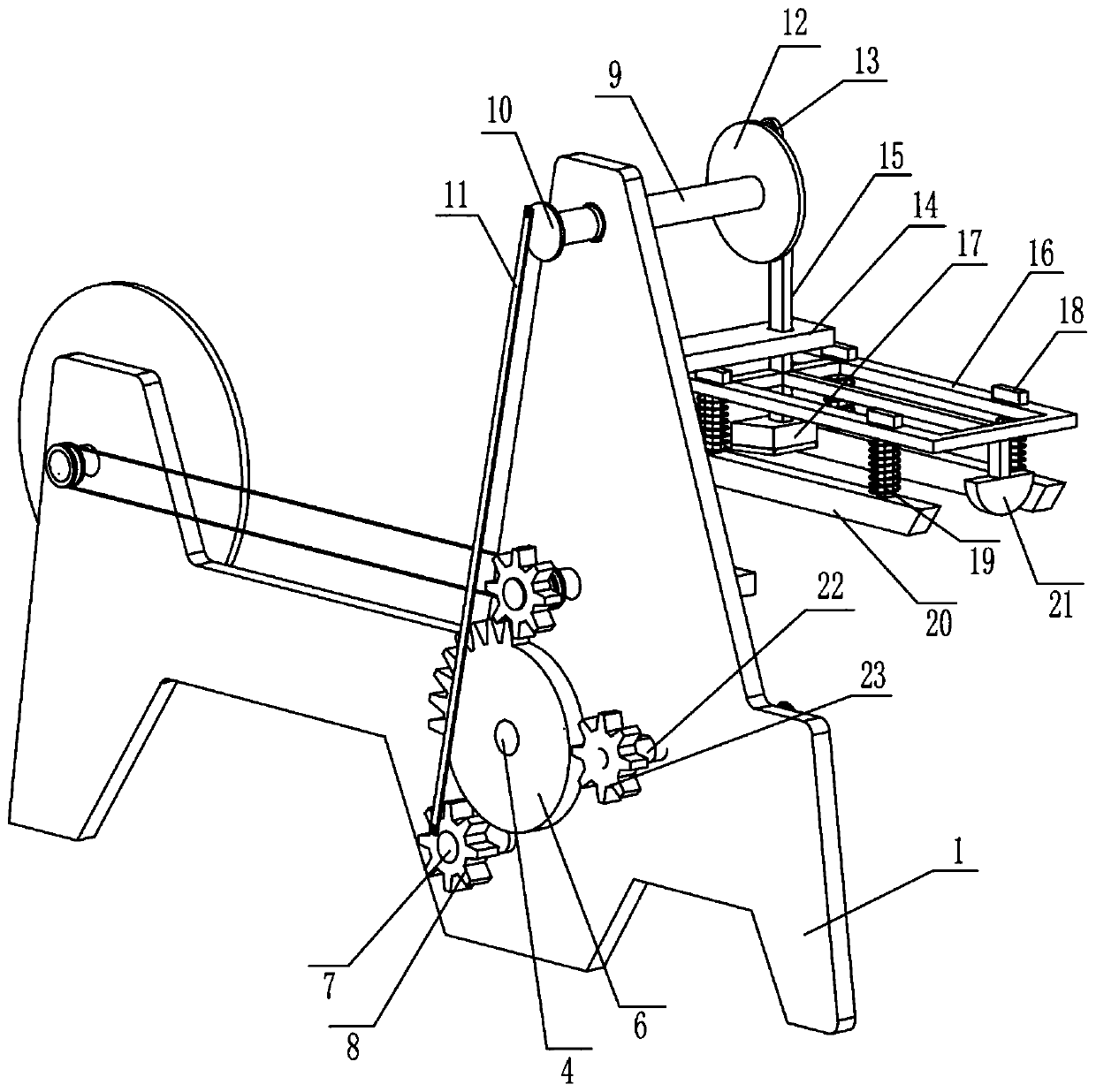

[0018] A paper gift bag intercepting device, such as Figure 1-5 As shown, it includes front support 1, rear support 2, supporting plate 3, motor 4, machine table 5, sector gear 6, first rotating shaft 7, first gear 8, upper rotating shaft 9, first turntable 10, connecting Rod one 11, second turntable 12, connecting rod two 13, guide plate 14 and descending body 15 and intercepting mechanism, described front support 1 is fixedly installed with pallet 3 by welding, and described motor 4 is installed on the pallet On the plate 3, the machine table 5 is fixedly installed on the rear support 2 by welding, the sector gear 6 is installed on the output shaft of the motor 4, and the first rotating shaft 7 is installed on the front support 1 through a bearing. Above, the first gear 8 is installed on one end of the first rotating shaft 7 and meshes with the sector gear 6, the upper rotating shaft 9 is installed on the upper right part of the front bracket through a bearing, and the firs...

Embodiment 2

[0020] On the basis of Example 1, such as Figure 1-5 As shown, the intercepting mechanism capable of intercepting paper gift bags includes a down frame 16, a cutter 17, a connecting body 18, a first spring 19, a trapezoidal pressing block 20 and an ejection block 21, and the down frame 16 passes through The way of welding is fixedly installed on the descending body 15, the cutter 17 is fixedly installed on one end of the descending body 15 by welding, and the four connecting bodies 18 are slidably installed on the descending frame 16 and the connecting body 18 can move 16 slides up and down, and the two trapezoidal pressing blocks 20 that can squeeze the paper gift bag are fixedly installed on the lower end of the connecting body 18 by welding, one end of the first spring 19 is installed on the down frame 16, and the other end is installed on the trapezoidal On the pressure block 20 and passed through by the connecting body 18, the ejection block 21 is fixedly installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com