A kind of rubber compound for elastic joint and preparation method thereof

A rubber compound and elastic node technology, applied in the field of polymer materials, can solve the problem that the rubber compound fails to meet the requirements of combustion performance standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

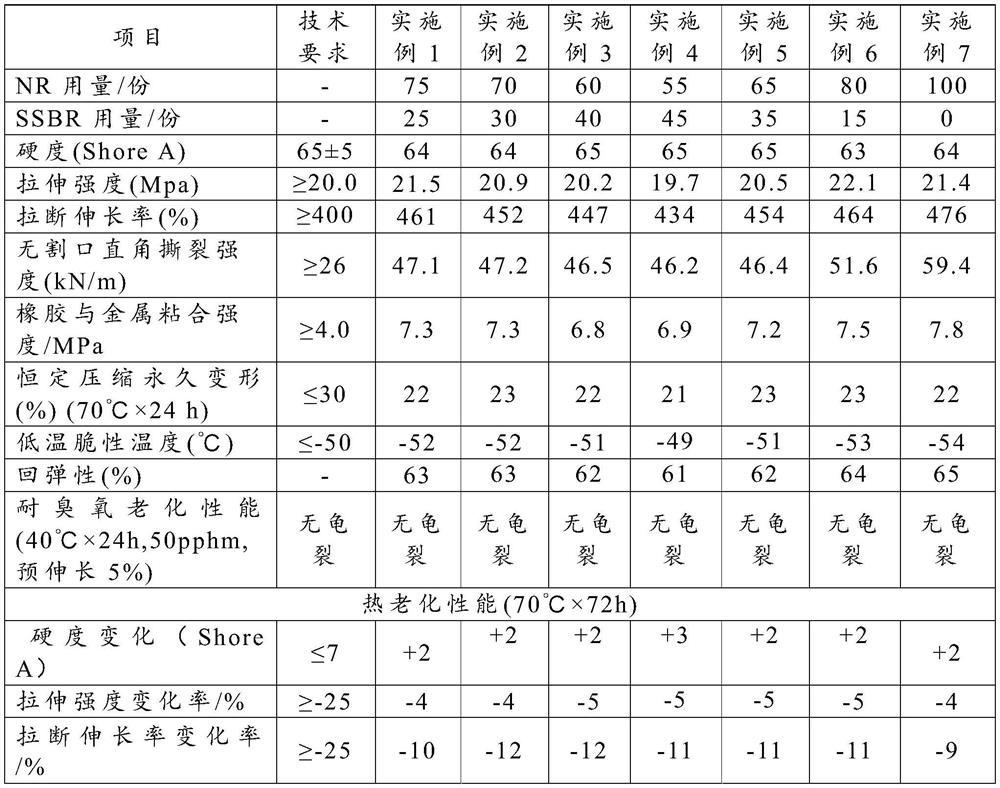

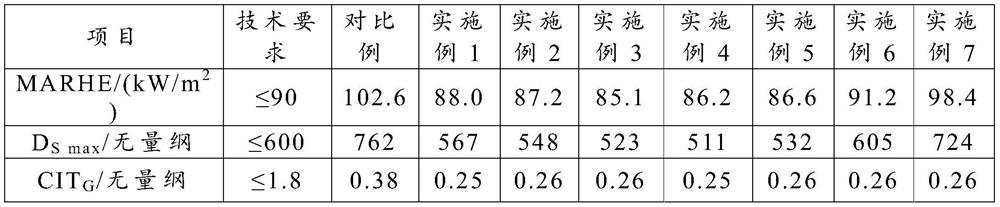

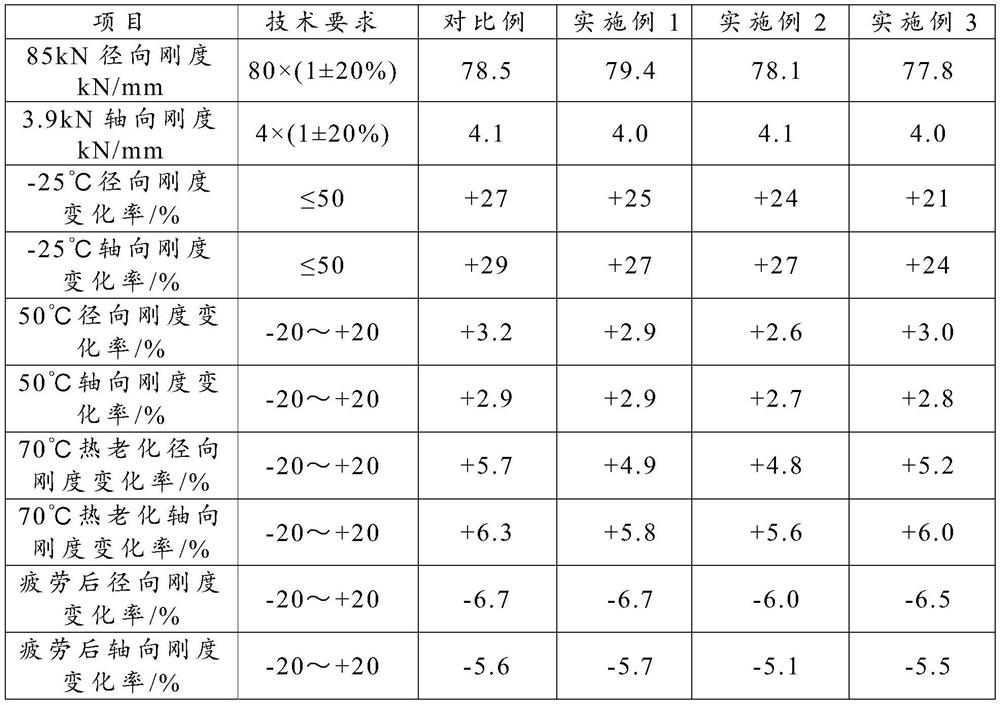

Examples

Embodiment 1

[0047] A rubber compound for elastically node, the rubber compound component comprising, in parts by mass:

[0048] 75 parts of natural rubber, 25 parts of solution SBR, 3.5 parts of zinc oxide, 1.5 parts of stearic acid, 30 parts of white carbon, 30 parts of carbon black, 3 parts antioxidant 4010NA, 2 parts of antioxidant RD, 3 parts of paraffin modifier 3.5 parts, 12 parts of naphthenic oil, a high molecular weight ammonium polyphosphate Form -Ⅱ 8 parts, 1 part of sulfur, phenylene among N, N'- bis-maleimide 0.5 parts of an accelerator of TBzTD parts of accelerator TBBS 2 parts.

[0049] The specific preparation steps are as follows:

[0050] Key process parameters and manufacturing equipment: nominal volume (90 ~ 250) L of intermeshing mixer, the temperature control unit disposed within a temperature range of 30 ~ 40 ℃, ram pressure 0.45 ~ 0.6MPa. The following steps 1 to 5 mixer rotor speed of 35 ~ 45r / min, rotor speed mixer having 6 to step 7 15 ~ 20r / min.

[0051] Step 1...

Embodiment 2

[0059] A rubber compound for elastically node, the rubber compound component comprising, in parts by mass:

[0060] 70 parts of natural rubber, 30 parts of solution SBR, 5 parts of zinc oxide, 2 parts of stearic acid, 25 parts of white carbon, 30 parts of carbon black, antioxidant 4010NA 2.5 parts of antioxidant RD 1 part, 2 parts of paraffin wax , 2.5 parts of modifying agent, 8 parts of naphthenic oil, high molecular weight Form -Ⅱ 5 parts of ammonium polyphosphate, 1.3 parts of sulfur, phenylene among N, N'- bismaleimide, 0.8 parts of accelerator TBzTD 0.6 parts of accelerator TBBS 1.6 parts.

[0061] Key process parameters and manufacturing equipment: nominal volume (90 ~ 250) L of intermeshing mixer, the temperature control unit disposed within a temperature range of 30 ~ 40 ℃, ram pressure 0.45 ~ 0.6MPa. The following steps 1 to 5 mixer rotor speed of 35 ~ 45r / min, rotor speed mixer having 6 to step 7 15 ~ 20r / min.

[0062] Step 1: natural rubber, solution styrene butadi...

Embodiment 3

[0070] A rubber compound for elastically node, the rubber compound component comprising, in parts by mass:

[0071] 60 parts of natural rubber, 40 parts of SSBR, 8 parts zinc oxide, 2 parts of stearic acid, 20 parts of white carbon, 30 parts of carbon black, 1.5 parts antioxidant 4010NA, RD 1 parts antioxidant, 1.5 parts of paraffin , 2 parts modifier, 5 parts of naphthenic oil, high molecular weight ammonium polyphosphate -Ⅱ Form 3 parts, 2 parts of sulfur, phenylene among N, N'- bismaleimide, 1 part of accelerator TBzTD 0.3 parts of accelerator TBBS 1.2 parts.

[0072] Key process parameters and manufacturing equipment: nominal volume (90 ~ 250) L of intermeshing mixer, the temperature control unit disposed within a temperature range of 30 ~ 40 ℃, ram pressure 0.45 ~ 0.6MPa. The following steps 1 to 5 mixer rotor speed of 35 ~ 45r / min, rotor speed mixer having 6 to step 7 15 ~ 20r / min.

[0073] Step 1: natural rubber, solution styrene butadiene rubber into the mixer, mixing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com