A kind of rubber compound of hourglass spring and preparation method thereof

A technology of rubber compound and hourglass spring, applied in the field of polymer materials, can solve the problem that the rubber compound fails to meet the requirements of combustion performance standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

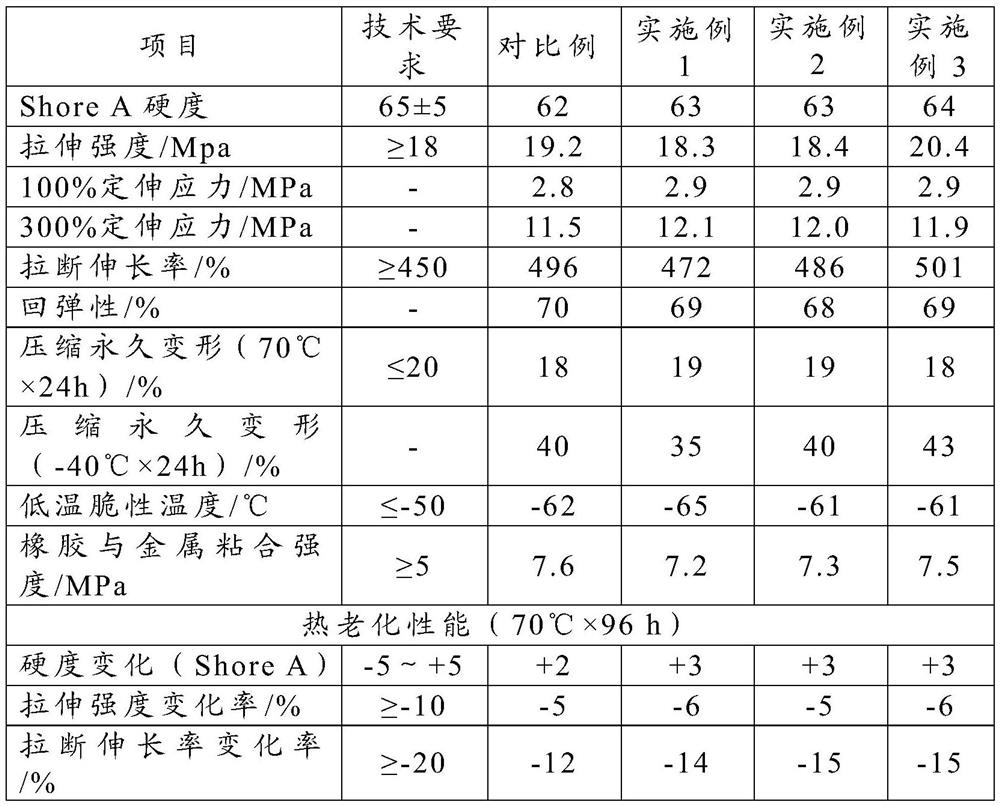

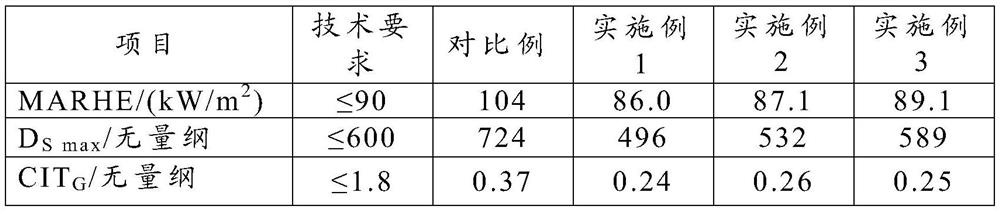

Examples

Embodiment 1

[0050] A rubber compound for an hourglass spring, the rubber compound component comprises, in parts by mass:

[0051] 55 parts of natural rubber, 30 parts of low-cis polybutadiene rubber, 15 parts of solution polystyrene butadiene rubber, 5 parts of zinc oxide, 2 parts of stearic acid, 1.7 parts of sulfur, 0.6 parts of accelerator TBTD, 1.5 parts of accelerator CBS , 25 parts of white carbon black, 25 parts of carbon black, 2 parts of anti-aging agent 4010NA, 1 part of anti-aging agent RD, 2 parts of paraffin, 2.5 parts of modifier, 3 parts of toluene diphenyl phosphate, 6 parts of naphthenic oil, high molecular weight 8 parts of crystal form-II ammonium polyphosphate.

[0052] Concrete preparation steps are as follows:

[0053] Manufacturing equipment and key process parameters: intermeshing type internal mixer with nominal volume (90-250) L, temperature control unit temperature setting within 30-40 °C, upper jacking bolt pressure 0.45-0.6 MPa. The internal mixer rotor spee...

Embodiment 2

[0062] A rubber compound for an hourglass spring, the rubber compound component comprises, in parts by mass:

[0063] 60 parts of natural rubber, 20 parts of low-cis polybutadiene rubber, 20 parts of solution polystyrene butadiene rubber, 7 parts of zinc oxide, 4 parts of stearic acid, 3 parts of sulfur, 1.6 parts of accelerator TBTD, 2.8 parts of accelerator CBS 25 parts of white carbon black, 25 parts of carbon black, 4 parts of antioxidant 4010NA, 2 parts of antioxidant RD, 2 parts of paraffin, 3.5 parts of modifier, 3 parts of toluene diphenyl phosphate, 6 parts of naphthenic oil, high molecular weight 4 parts of crystal form-II ammonium polyphosphate.

[0064] Concrete preparation steps are as follows:

[0065] Manufacturing equipment and key process parameters: intermeshing type internal mixer with nominal volume (90-250) L, temperature control unit temperature setting within 30-40 °C, upper jacking bolt pressure 0.45-0.6 MPa. The internal mixer rotor speed of the foll...

Embodiment 3

[0074] A rubber compound for an hourglass spring, the rubber compound component comprises, in parts by mass:

[0075] 70 parts of natural rubber, 20 parts of low-cis polybutadiene rubber, 10 parts of solution polystyrene butadiene rubber, 5 parts of zinc oxide, 2 parts of stearic acid, 1.7 parts of sulfur, 1 part of accelerator TBTD, 2.5 parts of accelerator CBS , 25 parts of white carbon black, 25 parts of carbon black, 1 part of anti-aging agent 4010NA, 0.5 part of anti-aging agent RD, 2 parts of paraffin, 2.5 parts of modifier, 2 parts of toluene diphenyl phosphate, 4 parts of naphthenic oil, high molecular weight crystal Type-II ammonium polyphosphate 10 parts.

[0076] Concrete preparation steps are as follows:

[0077] Manufacturing equipment and key process parameters: intermeshing type internal mixer with nominal volume (90-250) L, temperature control unit temperature setting within 30-40 °C, upper jacking bolt pressure 0.45-0.6 MPa. The internal mixer rotor speed of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com