Preparation method of green and environment-friendly flame-retardant wood-plastic plate

A green and environmentally friendly, wood-plastic board technology, applied in the direction of flat products, wood processing appliances, other household appliances, etc., can solve the problems of consumption of petrochemical products, low performance, increased production costs, etc., to meet the requirements of combustion performance, technology Simple process and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

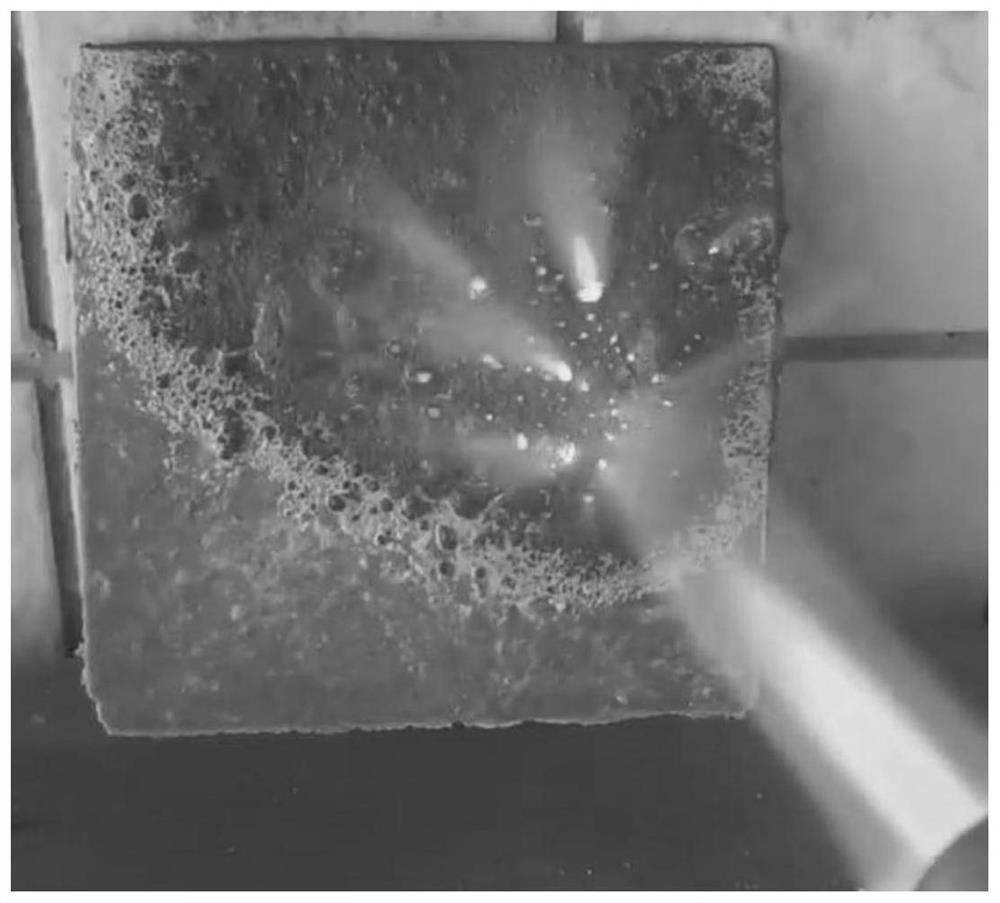

Image

Examples

Embodiment 1

[0028] (1) Weigh high amylose corn starch (amylose content 70%) and mix it with wood flour evenly, and the mass ratio is 6:14.

[0029] (2) Weigh calcium chloride solid, add it to water, and configure 40% calcium chloride solution.

[0030] (3) Add solution (2) to the mixed powder of (1) in a mass ratio of 20:3, and stir evenly.

[0031] (4) Spread the wet powder in (3) evenly in a metal mold of 10cm×10cm×1mm.

[0032] (5) The metal mold in (4) was placed on a hot press molding machine, the temperature was set to 105° C., the clamping pressure was 5 MPa, and the pressure holding time was 10 minutes.

[0033] (6) After the mold is cooled, take it out to obtain a wood-plastic board with a thickness of 1 mm.

[0034] (7) The tensile and bending properties of the wood-plastic board in (6) were measured. The tensile strength was 3.5MPa, the static bending strength was 26.5MPa, and the surface hardness was 90HC.

[0035] (8) Determination of the flame retardant properties of the ...

Embodiment 2

[0038] (1) Weigh high amylose corn starch (amylose content 50%) and mix it with wood flour evenly, and the mass ratio is 3:17.

[0039] (2) Weigh 30 g of calcium chloride solid, add it to 70 g of water, and configure a 30% calcium chloride solution.

[0040] (3) Add the solution (2) to the mixed powder of (1) in a mass ratio of 20:3, and stir evenly.

[0041] (4) Spread the wet powder in (3) evenly in a metal mold of 10cm×10cm×1mm.

[0042] (5) The metal mold in (4) was placed on a hot press molding machine, the temperature was set to 105° C., the clamping pressure was 5 MPa, and the pressure holding time was 10 minutes.

[0043] (6) After the mold is cooled, take it out to obtain a wood-plastic board with a thickness of 1 mm.

[0044] (7) The tensile and bending properties of the wood-plastic board in (6) were measured. The tensile strength was 1.5MPa, the bending stress was 17.2MPa, and the surface hardness was 90HC.

[0045] (8) Determination of the flame retardant prope...

Embodiment 3

[0047] (1) Weigh high amylose corn starch (amylose content 50%) and mix it with wood flour evenly, and the mass ratio is 3:17.

[0048] (2) Weigh calcium chloride solid, add it to water, and configure 40% calcium chloride solution.

[0049] (3) Add solution (2) to the mixed powder of (1) in a mass ratio of 20:10, and stir evenly.

[0050] (4) Add the wet powder in (3) into an injection molding machine, and at a processing temperature of 95° C., extrude and inject into a wood-plastic board with a thickness of 3 mm.

[0051] (5) Determine the tensile and bending properties of the wood-plastic board in (4), the tensile strength is 5.5MPa, the static bending strength is 35MPa, and the surface hardness is 98HC.

[0052] (6) Determination of the flame retardant properties of the wood-plastic board in (4). According to GB / T 2408-2008 Test Method B-Vertical Burning Test, the after-flame time of a single sample after the first application of flame is 0 seconds, and the after-flame ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com