Preparation method of halogen free flame retardation polypropylene bulked filament

A technology of expanded filament and flame-retardant polypropylene, which is applied in the manufacture of fire-resistant and flame-retardant filaments, the melting of filament raw materials, and single-component polyolefin artificial filaments. It can solve the problem of increased raw material costs and flame-retardant polypropylene expansion Filament is difficult to accept in the market, not economical, etc., to achieve the effect of low fiber spinning cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

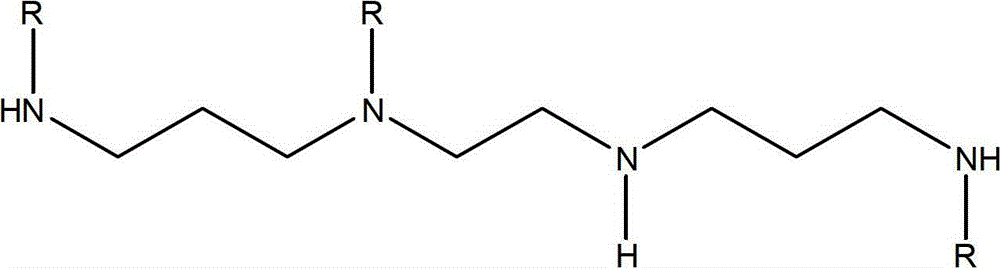

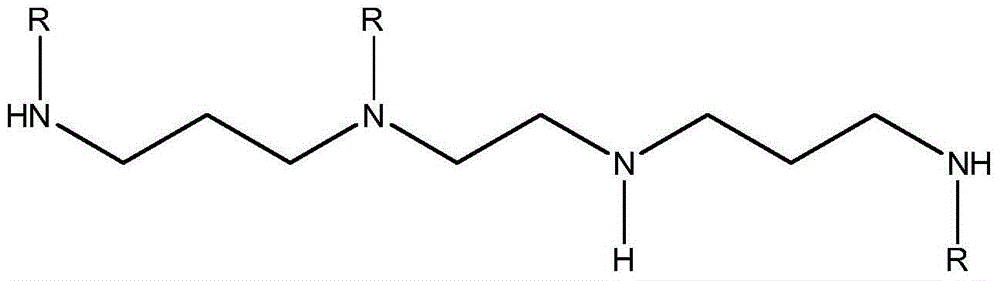

[0039] a. Preparation of halogen-free flame retardant masterbatch: take 44.8% polypropylene chips, 39.2% compound halogen-free flame retardant (of which: 2.0% hindered amine flame retardant I, 18.9% intumescent flame retardant I , 5.1% intumescent flame retardant II, 10.8% tetraphenylresorcinol diphosphate, 2.4% zinc acetylacetonate), 16% maleic anhydride grafted polypropylene into the high-speed mixer, after After pre-mixing by a high-speed mixer, add it to a twin-screw extruder, and then melt, mix and granulate it through a twin-screw extruder at a temperature of 210°C to 230°C to obtain a flame-retardant masterbatch;

[0040] b. Spinning: Mix 100 kg of the above-mentioned flame-retardant masterbatch, 296 kg of polypropylene slices, and 4 kg of light brown color masterbatch in proportion, and spin through the BCF spinning unit, using the same spinning method as the conventional polypropylene bulked filament. Fiber process to obtain halogen-free flame-retardant polypropylene ...

Embodiment 2

[0046] a. Preparation of halogen-free flame retardant masterbatch: take 41% polypropylene chips, 47% compound halogen-free flame retardant (of which: 5% hindered amine flame retardant I, 22.5% intumescent flame retardant I , 2% trineopentyl glycol diphosphate, 15% tetraphenylresorcinol diphosphate, 2.5% zinc acetylacetonate), 12% solubilizing and dispersing agent into the high-speed mixer, through the high-speed After pre-mixing in the mixer, add it to the twin-screw extruder, and then melt, mix and granulate it through the twin-screw extruder at a temperature of 210 ° C to 230 ° C to obtain flame-retardant masterbatches;

[0047] (2) Spinning: Mix 100 kg of the above-mentioned flame-retardant masterbatch, 395 kg of polypropylene chips, and 5 kg of light brown color masterbatch in proportion, and spin through the BCF spinning unit, using the same fiber as conventional polypropylene bulked filament Spinning process to obtain halogen-free flame-retardant polypropylene bulked fil...

Embodiment 3

[0053] a. Preparation of halogen-free flame retardant masterbatch: take 47.5% polypropylene chips, 40.5% compound halogen-free flame retardant (of which: 5% hindered amine flame retardant I, 18% intumescent flame retardant I , 5% intumescent flame retardant II, 10% tetraphenylresorcinol diphosphate, 2.5% zinc acetylacetonate), 12% solubilizing dispersant into the high-speed mixer, through the high-speed mixer After pre-mixing, add it to a twin-screw extruder, and then melt, mix and granulate it through the twin-screw extruder at a temperature of 210°C to 230°C to obtain a flame-retardant masterbatch;

[0054] b. Spinning: Mix 100 kg of the above-mentioned flame-retardant masterbatch, 392.5 kg of polypropylene chips, and 7.5 kg of brown color masterbatch in proportion, and spin through the BCF spinning unit, using the same spinning method as the conventional polypropylene bulked filament process to obtain halogen-free flame-retardant polypropylene bulked filaments. Among them,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com