Bucket tooth, bucket and excavator

A technology for excavators and buckets, which is applied in the field of construction machinery, can solve problems such as difficulty in the disassembly and assembly of the tooth head, potential safety hazards, and a large cost of tooth pins, so as to save time and effort in the disassembly and assembly of bucket teeth, improve operating efficiency, The safety effect of the disassembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

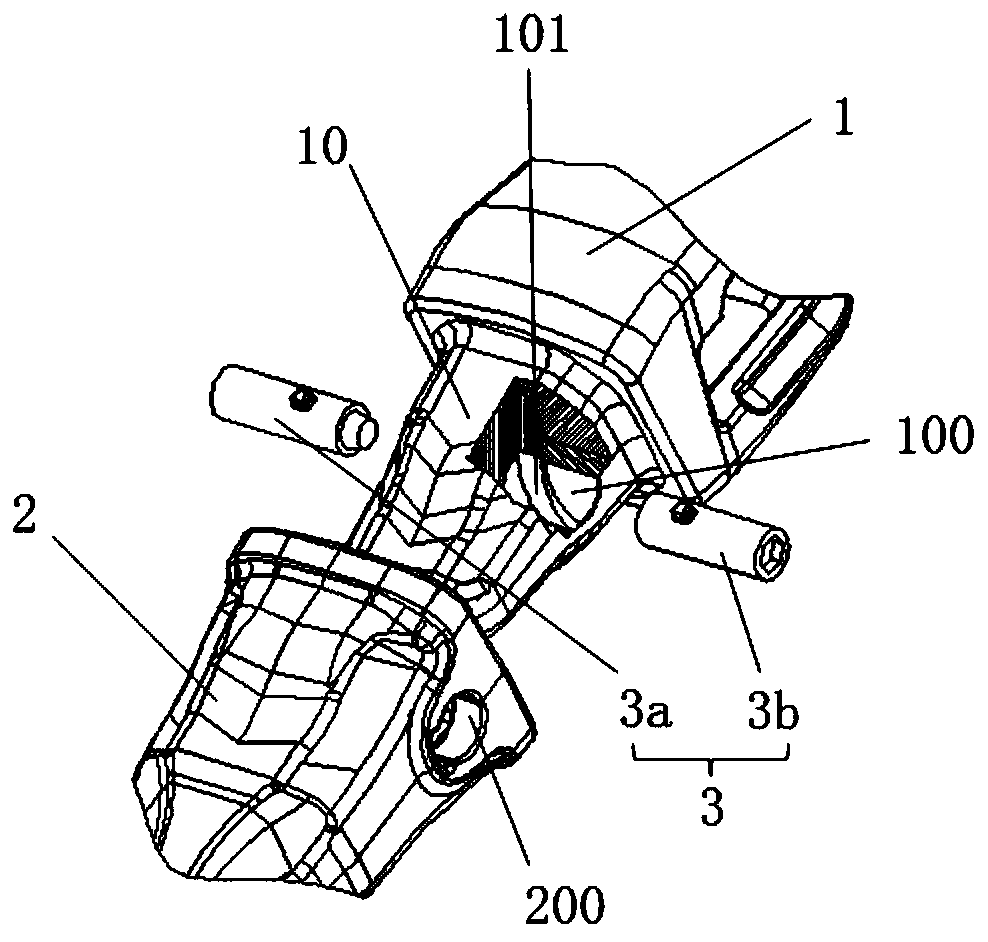

[0040] See figure 1 , The bucket tooth provided in this embodiment is applied to the bucket in construction machinery, such as excavators, loaders and other construction machinery. The bucket is an important part of the working device of this type of construction machinery, and the bucket teeth are Important parts of excavators are prone to wear out after long-term operation and need to be replaced.

[0041] The traditional bucket teeth are difficult to install and disassemble. The main reason is that the connecting pin needs to be directly driven with a hammer with great strength, and there are great safety hazards in the beating process. In addition, the connecting pin after disassembly will be deformed to a certain extent, which seriously affects the secondary use of the connecting pin.

[0042] The starting point of this embodiment is to solve the problems in the prior art by providing a bucket tooth that can be installed and disassembled without beating, has a simple structure...

Embodiment 2

[0072] See Figure 1 to Figure 8 , The bucket tooth provided in this embodiment is applied to buckets in construction machinery, such as excavators, loaders and other construction machinery. The starting point of this embodiment is to solve the problems in the prior art by providing a bucket tooth that can be installed and disassembled without beating, has a simple structure, is convenient and quick to disassemble and assemble, and the disassembly process is safer. Compared with the first embodiment above, this embodiment has the following main differences:

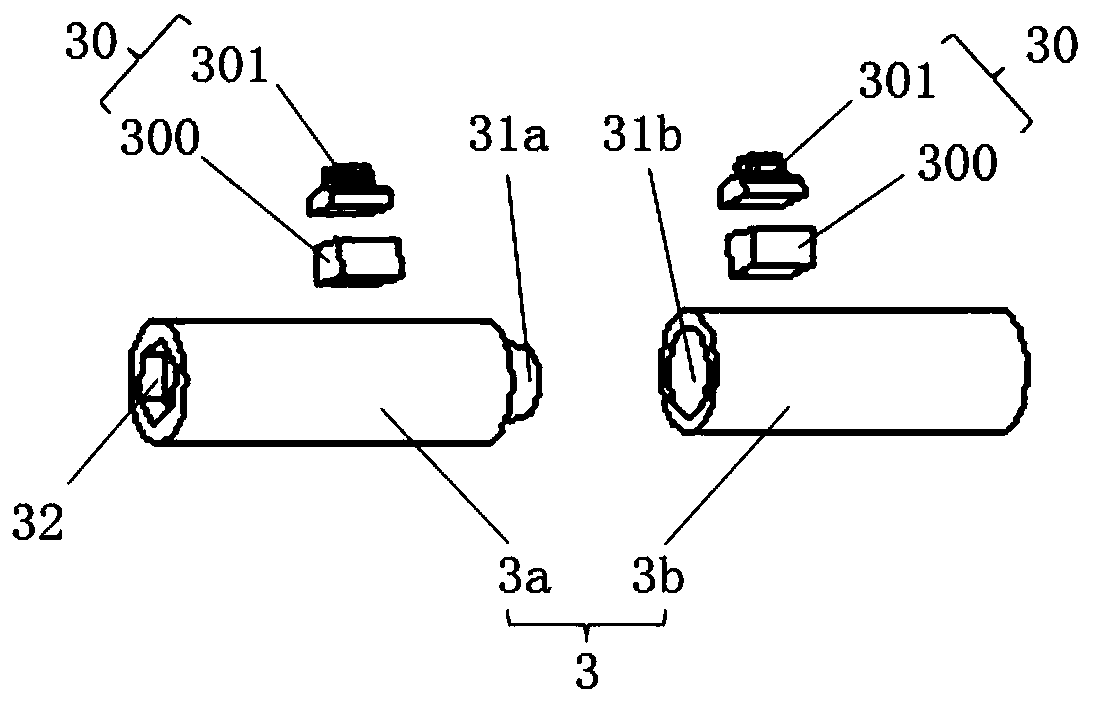

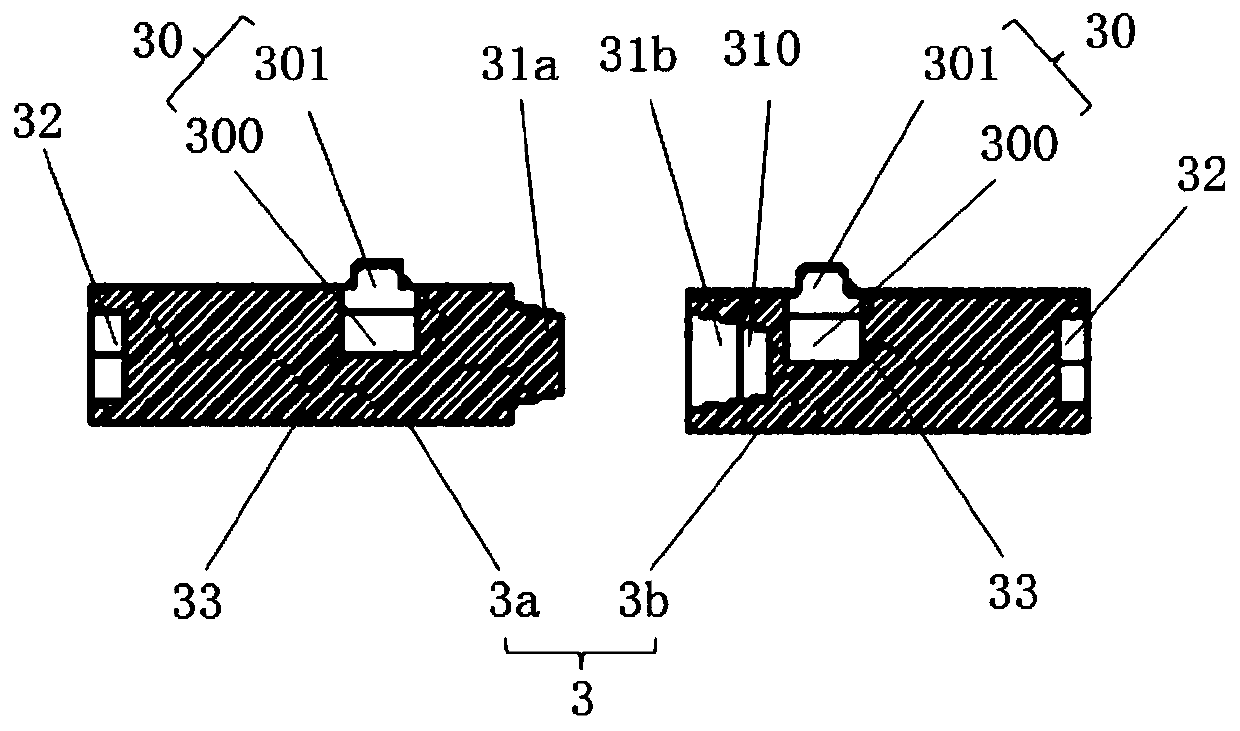

[0073] For details, please refer to figure 2 with image 3 In this embodiment, the boss 30 is in clearance fit with the groove 33 on the outer arc surface of the connecting pin 3, and the boss 30 is an elastic boss 30. It can be understood that the elastic boss 30 can be relatively telescopic in the groove 33, and then the boss 30 can enter the track 101 after being compressed, and generate a thrust to the track 101, and t...

Embodiment 3

[0083] See Figure 1 to Figure 8 , The bucket tooth provided in this embodiment is applied to buckets in construction machinery, such as excavators, loaders and other construction machinery. The starting point of this embodiment is to solve the problems in the prior art by providing a bucket tooth that can be installed and disassembled without beating, has a simple structure, is convenient and quick to disassemble and assemble, and the disassembly process is safer. Compared with the above-mentioned first or second embodiment, the main difference between this embodiment is:

[0084] For details, please refer to figure 2 with image 3 In this embodiment, the pair of connecting pins 3 are the first pin 3a and the second pin 3b, respectively. The first pin 3a and the second pin 3b are in interference fit in the second shaft hole 100, in other words Therefore, the opposite ends of the first pin 3a and the second pin 3b are matched with each other.

[0085] It is understandable that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com