Rapid pressure release valve and integrated type diaphragm pump adopting rapid pressure release valve assembly

A pressure relief valve and diaphragm pump technology, applied to pumps with flexible working elements, liquid displacement machines, pumps, etc., can solve the problem of difficult control of channel cross-sectional area, uncontrollable ventilation volume, uncontrollable depressurization speed, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

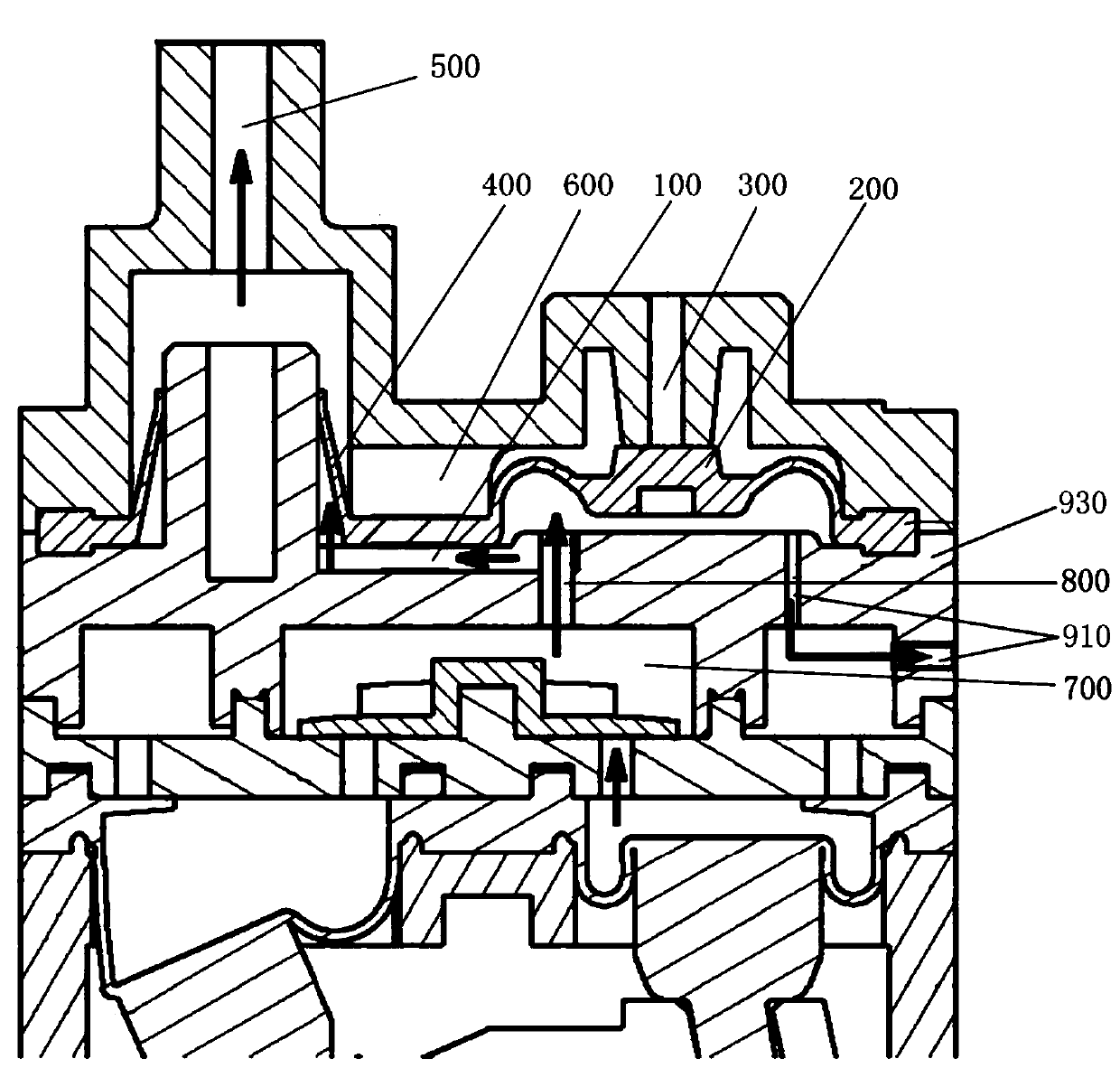

Method used

Image

Examples

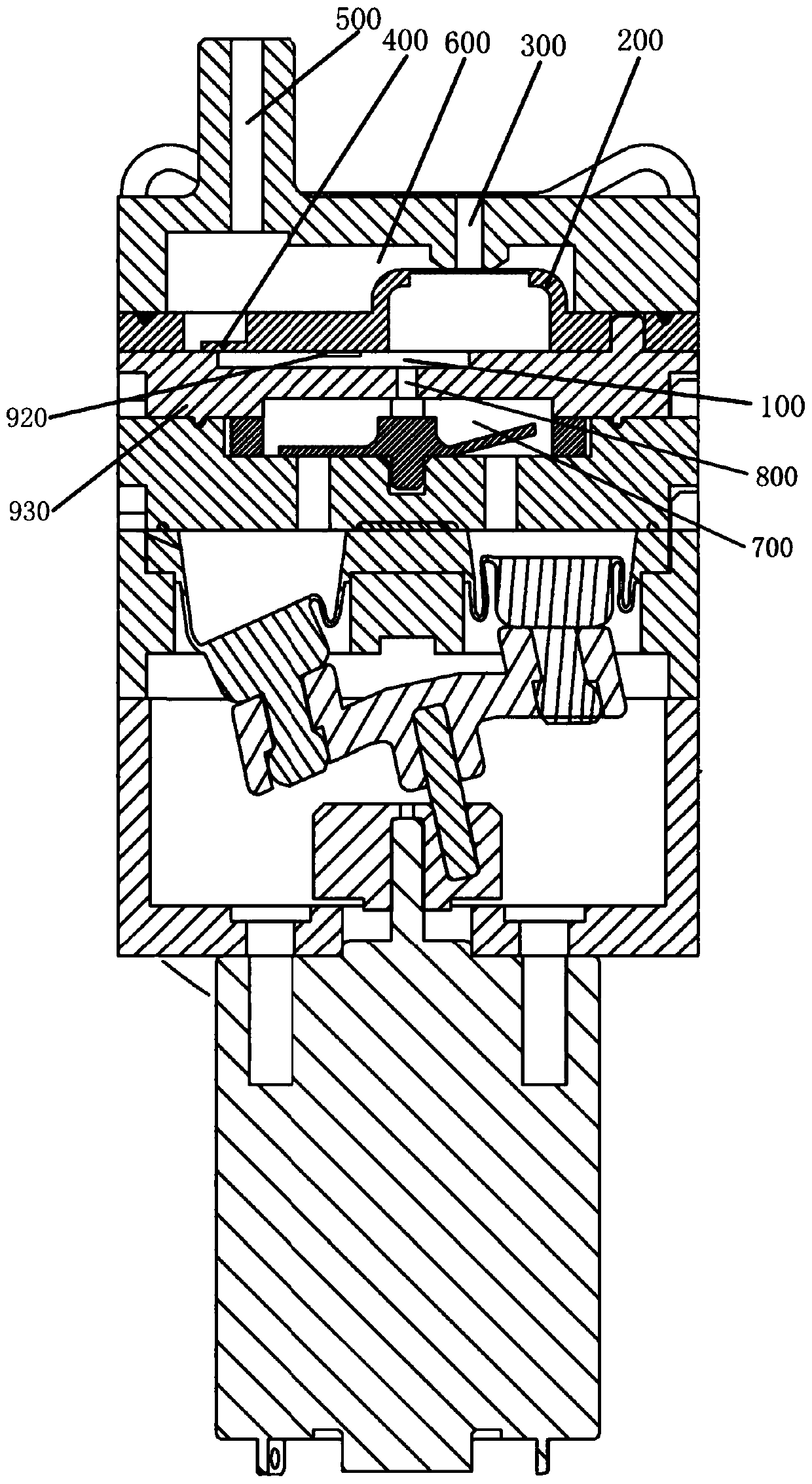

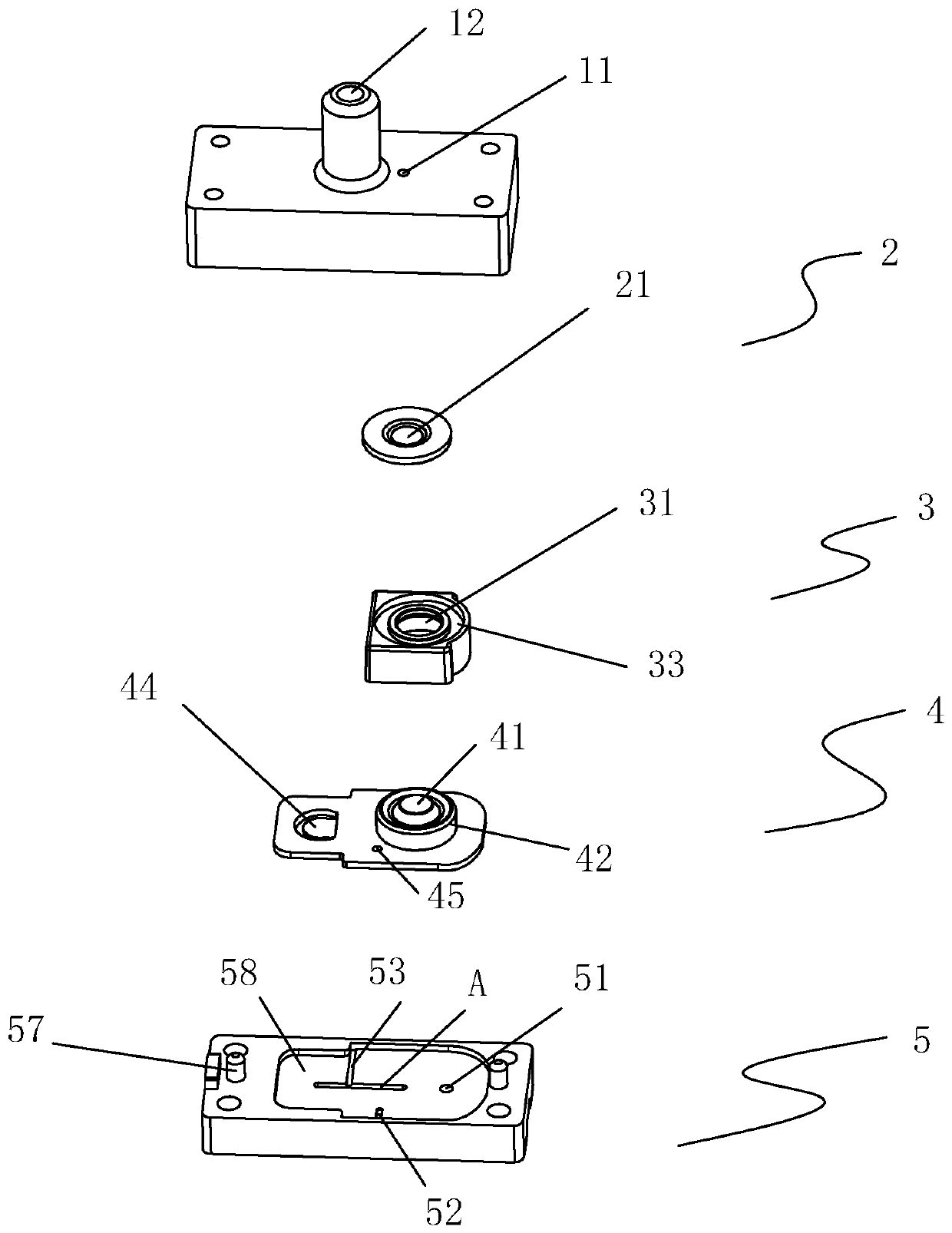

Embodiment 3

[0078] The structure of the integrated diaphragm pump in embodiment three is as follows: Figure 28 As shown, it has a motor 7, a base 8, an eccentric wheel 71, a drive shaft 72, a support frame 73, an air bag 61, an air bag seat 6, a valve seat 62, an air outlet valve 63, a diaphragm positioning plate 5, and the above-mentioned quick pressure relief valve assembly and top cover 1. The motor 7 is installed on the base 8, and the airbag seat 6 is assembled on the base 8. Air bag 61 can specifically have two, and air bag 61 is installed on the air bag seat 6, and the bottom of air bag 61 is connected with support frame 73, and motor 7 drives air bag 61 action by eccentric wheel 71, drive shaft 72 and support frame 73 and inflates. The improvement points are: the valve seat 62, the diaphragm positioning plate 5, the above-mentioned quick pressure relief valve assembly and the upper cover 1 are sequentially assembled on the airbag seat 6. The difference between the third embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com