Marine automatic cable laying robot

An automatic laying and robot technology, applied in the direction of cable laying equipment, etc., can solve the problems of wasting time and resources, low construction efficiency, etc., and achieve the effect of reducing work intensity, improving laying efficiency, and reducing human resource investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

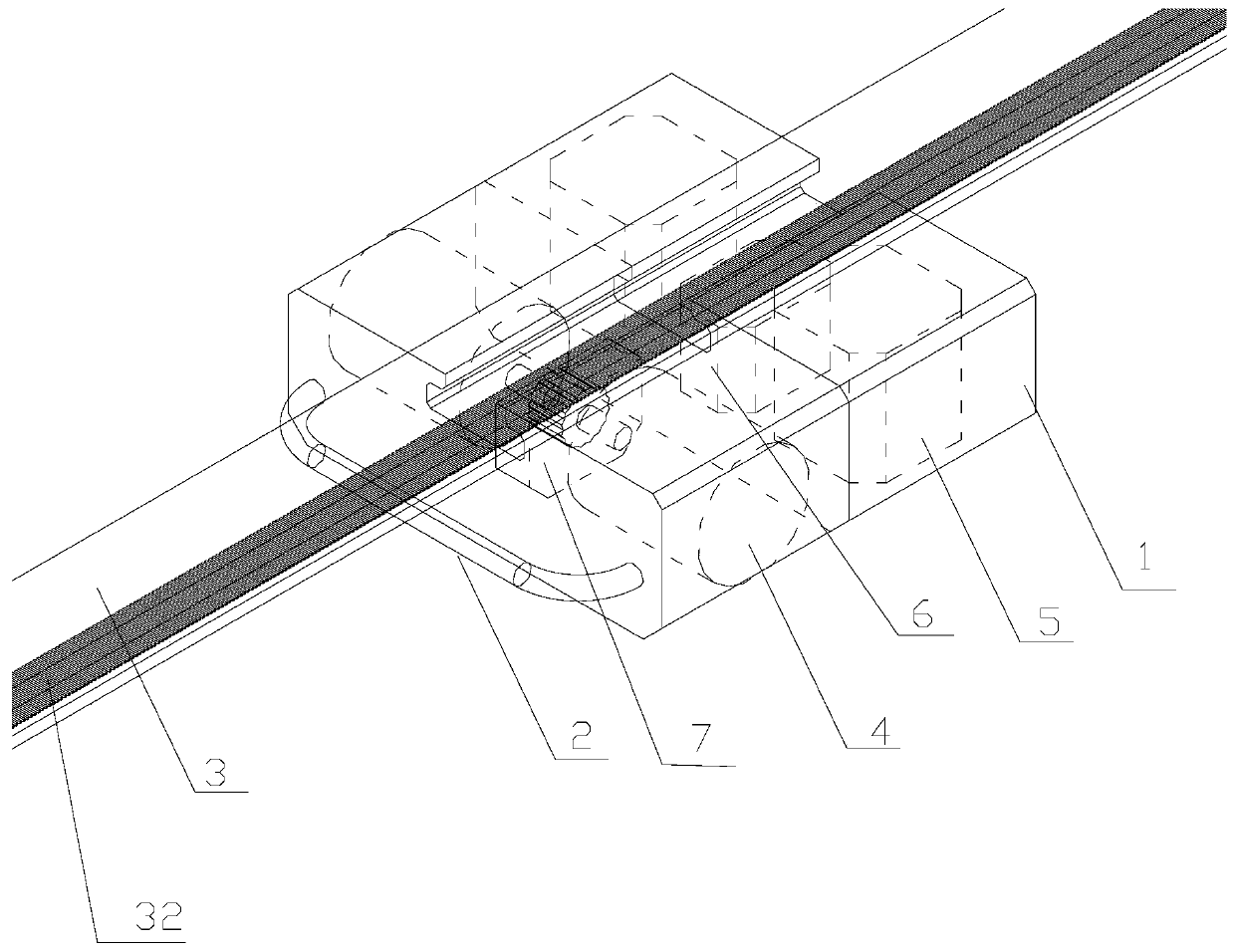

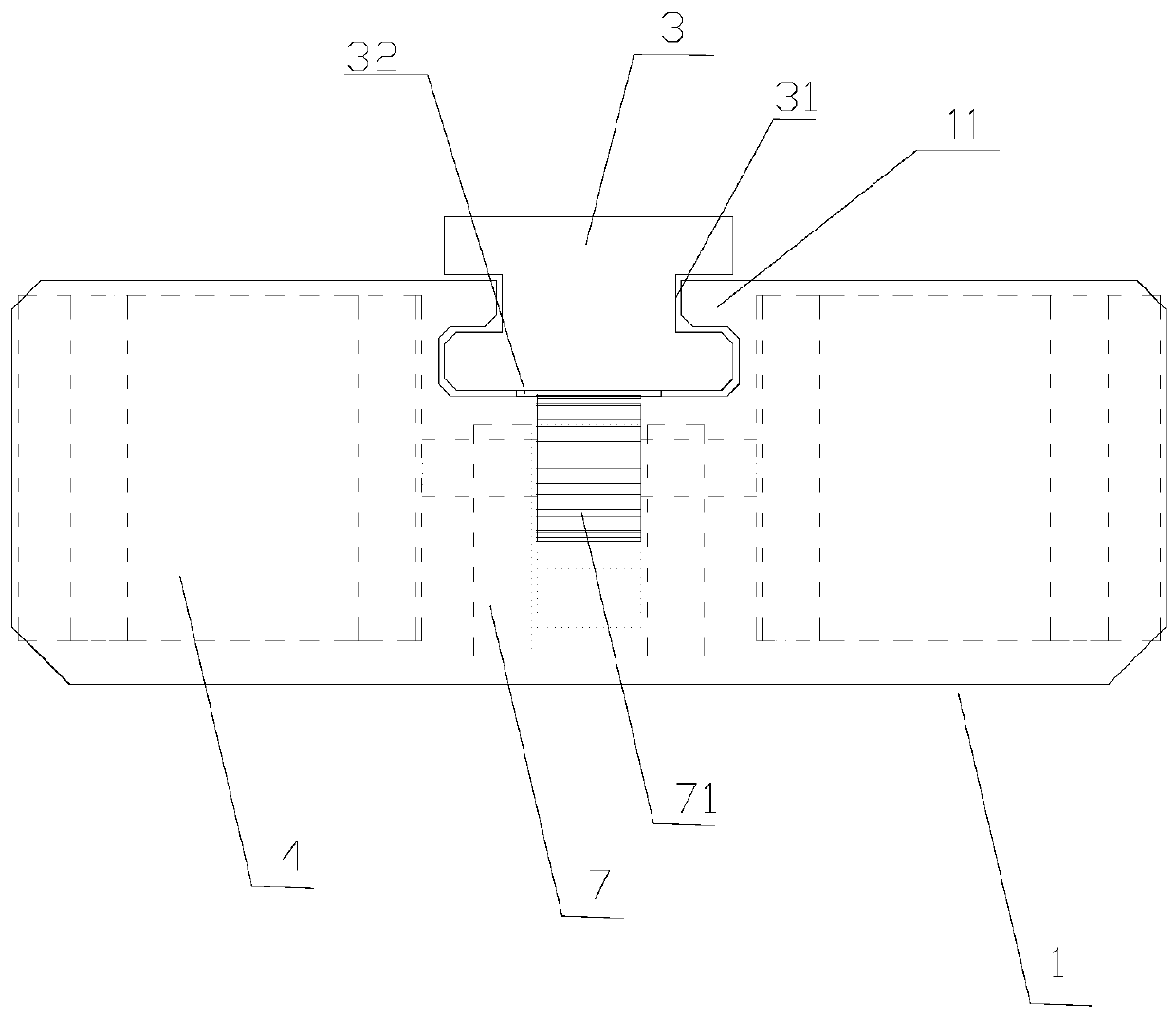

[0022] see figure 1 with figure 2 , The marine automatic cable laying robot of the present invention includes: an installation box 1, a cable binding fixture 2, a robot walking guide rail 3, a pair of motors 4, a pair of lithium batteries 5, a control module 6 and a motor gearbox 7.

[0023] The two sides of robot walking guide rail 3 have chute 31, and the bottom center is provided with rack track 32. The center of the installation box 1 is provided with a groove that fits with the walking guide rail 3 of the robot, and the two sides of the groove are provided with raised lines 11 that fit with two slide grooves 31 .

[0024] Two motors 4 are symmetrically fixed inside the installation box 1 on both sides of the robot walking guide rail 3 . The motor gearbox 7 is fixed inside the installation box 1 between the two motors 4, and is positioned directly below the robot wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com