Optical fiber dispensing device and flexible mesh-shaped optical fiber belt automatic production device

A technology of dispensing device and optical fiber, which is applied to the device, light guide, optics and other directions for coating liquid on the surface. Solve the effect of slow dispensing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

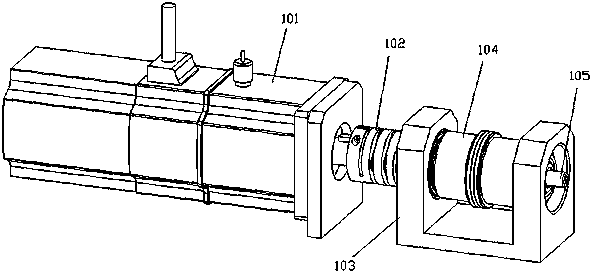

[0045] Such as figure 1 As shown, an optical fiber dispensing device includes a dispensing component and a driving component (such as a motor 101 ).

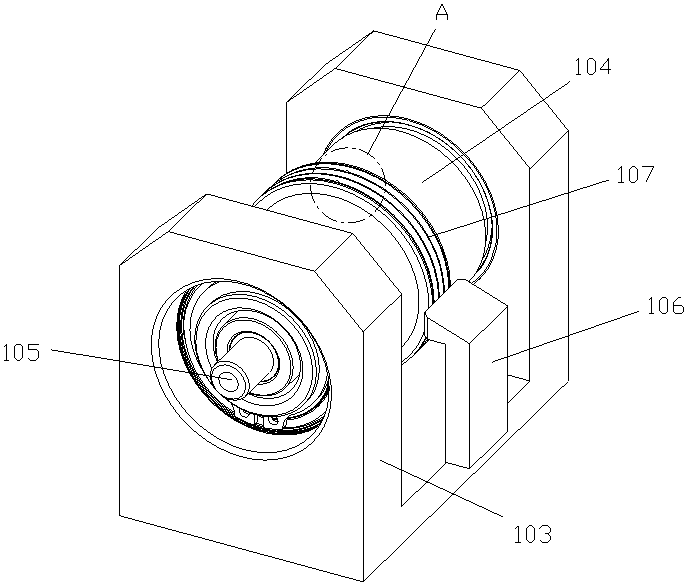

[0046] Such as figure 1 , 2 , 5, 7, and 8, the dispensing assembly includes a rotatable rotating shaft 104 and a fixed injection shaft 105, the rotating shaft 104 is a hollow structure with one end open, and the other end and the motor 101 pass through a coupling 102 connections. The rotating shaft 104 is sleeved on the glue injecting shaft 105 , the rotating shaft 104 is mounted on the fixing seat 103 through a bearing, and the glue injecting shaft 105 is fixedly connected with the fixing seat 103 .

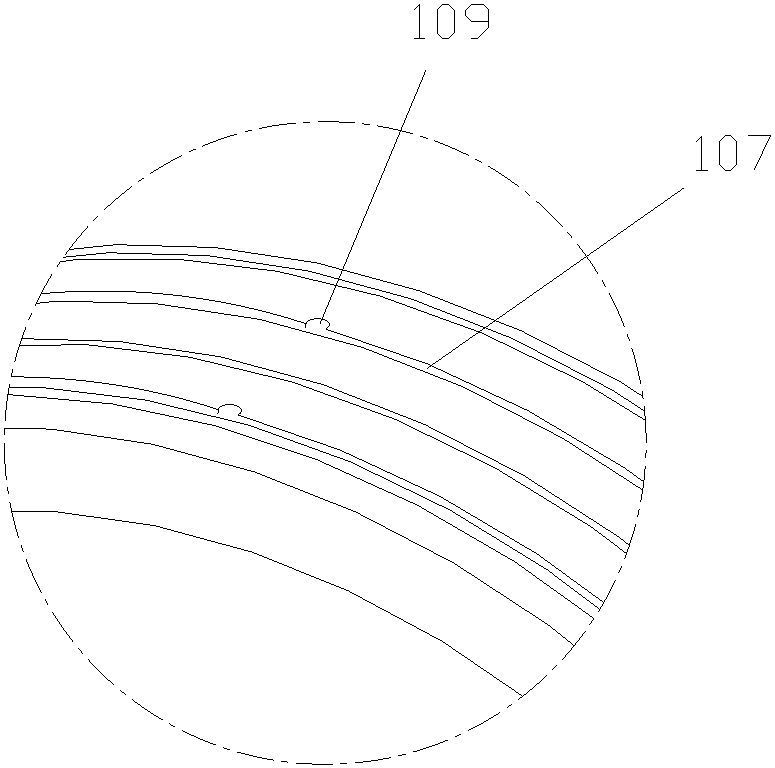

[0047] The rotating shaft 104 is provided with one or more axially parallel first dispensing holes 109 for connecting inside and outside. 1. When a plurality of first dispensing holes 109 are provided on the rotating shaft 104 (the preferred solution), such as Figure 5 , the first dispensing hole 109 is provided with four,...

Embodiment 2

[0052] In this embodiment, a squeegee 106 is added on the basis of the first embodiment, as figure 2 , 4 As shown, the squeegee 106 is fixedly installed on the fixed seat 103, and the squeegee 106 is matched with the outer surface of the rotating shaft 104 (including the limit groove 107), and is used to scrape off the centrifugal force when the rotating shaft 104 rotates at a high speed. The residual glue thrown out from the first glue dispensing hole 109.

Embodiment 3

[0054] This embodiment is an improvement made on the basis of the first embodiment.

[0055] Such as Figure 14-16 As shown, the limit groove 107 on the rotating shaft 104 is canceled, and an optical fiber positioning shaft 112 is added outside the rotating shaft 104, and the optical fiber positioning shaft 112 is sleeved on the outside of the rotating shaft 104; the rotating shaft 104 is installed on the fixed seat 103 through a bearing Above, the glue injection shaft 105 and the fiber positioning shaft 112 are fixedly connected with the fixed seat 103; the rotation shaft 104 is directly connected with the glue injection shaft 105 and the fiber positioning shaft 112 through bearings, and is sealed by a sealing ring.

[0056] When four first dispensing holes 109 are provided on the rotating shaft 104, four second dispensing holes 113 are arranged side by side on the upper side of the optical fiber positioning shaft 112, along with the rotating shaft 104 Rotating the first glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com