Adhesive dispensing device of LED lamp

A technology of dispensing device and LED lamp, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of difficult control, uneven dispensing, time-consuming and labor-intensive, etc., so as to avoid waste and improve dispensing. Effects of Speed and Dispensing Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

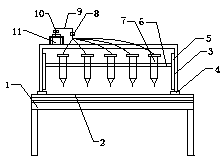

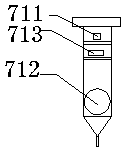

[0014] Such as Figure 1-2 As shown, a dispensing device for LED lamps includes a workbench 1, a first guide rail 2 is arranged horizontally on the top surface of the workbench 1, a bracket 3 is installed on the first guide rail 2, and the bottom of the bracket 3 The sliding shaft 4 is installed at the end, and the sliding shaft 4 is slidably connected with the first guide rail 2. The support 3 is fixedly provided with a vertical second guide rail 5, and the second guide rail 5 is equipped with a support rod 6. The support rod 6 is provided with a plurality of dispensing pens 7, the said dispensing pens 7 are provided with a quantitative control device, and the top of the support 3 is fixedly provided with a glue storage tank 11 for storing the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com