High-efficiency cleaning device and method for metal texture surface treatment of glass cabinets

A metal texture and surface treatment technology, which can be used in cleaning methods, cleaning methods and utensils using liquids, chemical instruments and methods, etc., and can solve problems such as difficult to achieve metal texture surface texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

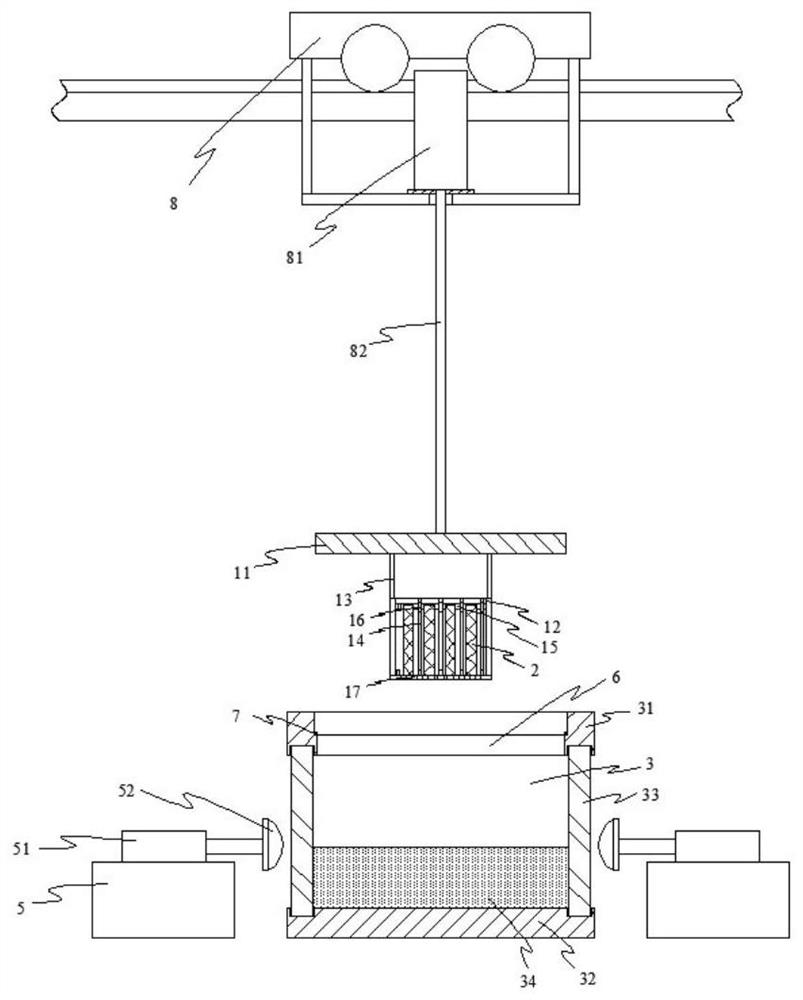

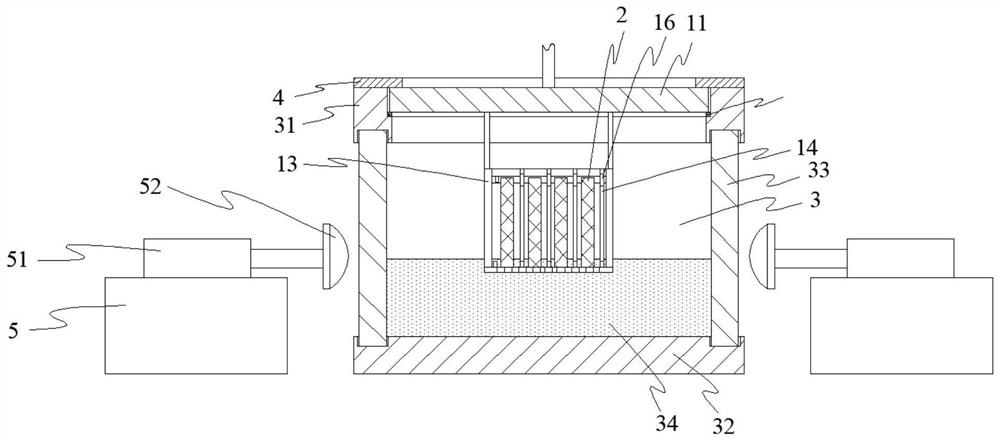

[0049] Please refer to Figure 1 to Figure 3 , a high-efficiency cleaning device for metal texture surface treatment of glass cabinets, used for cleaning the surface of glass cabinets 2 after metal texture surface treatment placed in a material basket 1, and the material basket 1 is provided with a top plate 11. The material basket frame 12 and the connecting column 13, the connecting column 13 is arranged between the top plate 11 and the material basket frame 12, the side of the material basket frame 12 is provided with a retaining column 14, and the said retaining column 14 is arranged at intervals, Spaces are provided between the retaining pillars 14, the outer surfaces of the retaining pillars 14 on both sides of the front and rear sides of the material basket frame 12 are also provided with cross bars 15, and the inner surfaces of the retaining pillars 14 on both sides of the front and rear sides of the material basket frame 12 are provided with positioning Stopper 16, th...

Embodiment 2

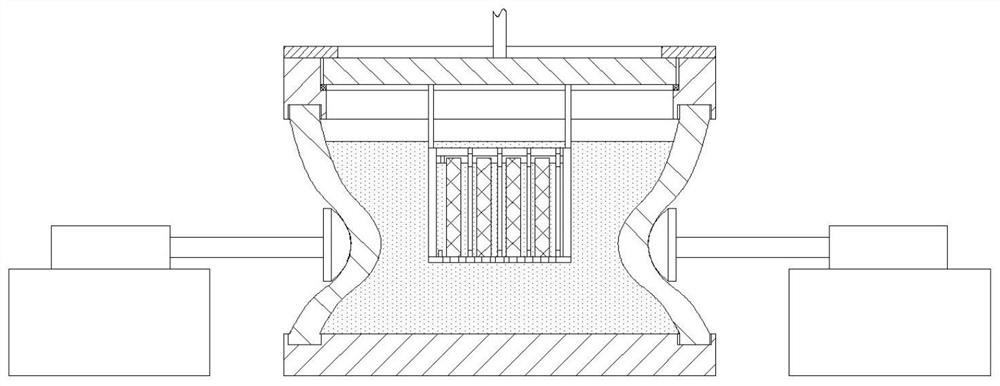

[0078] Please refer to Figure 4 to Figure 5 , the bottom hoop 32 is provided with a bottom elastic body 35, the bottom elastic body 35 is arranged in the central area of the bottom hoop 32, the bottom hoop 32 is provided with a second bonding groove, and the second bonding A second adhesive layer is arranged in the groove, and the outer end of the bottom elastic body 35 is bonded and fixed in the second adhesive groove through the second adhesive layer,

[0079] The ejector device 5 is provided with three, which are respectively arranged on the left and right sides of the elastic body side wall 33, and the ejector device arranged under the bottom hoop 32, and the ejector device under the bottom hoop 32. The ejector head of the ejector device is facing the bottom elastic body 35,

[0080] The material basket frame 12 enters the inside of the cleaning tank 3 from the center opening of the top hoop 31, and the elastic body side wall 33, the bottom elastic body 35, and the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com