Surface cleaning system

A surface cleaning and surface cleaning device technology, applied in cleaning equipment, cleaning devices, cleaning machinery and other directions, can solve the problems of difficult to clean the ground, affect the cleaning effect, poor cleaning effect, etc., to strengthen the scraping cleaning path and improve the overall Effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

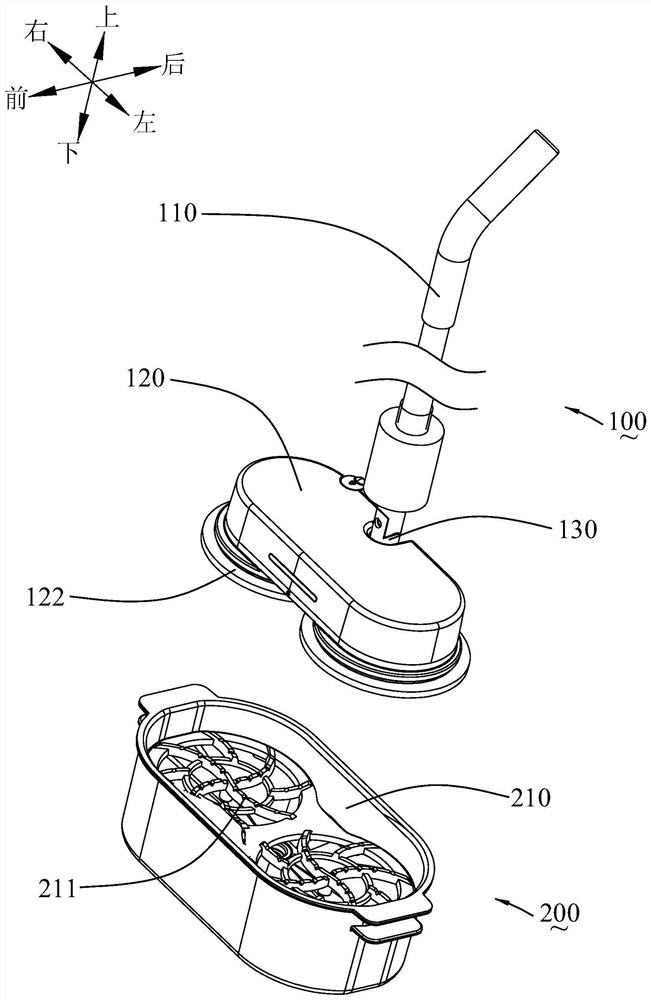

Embodiment 1

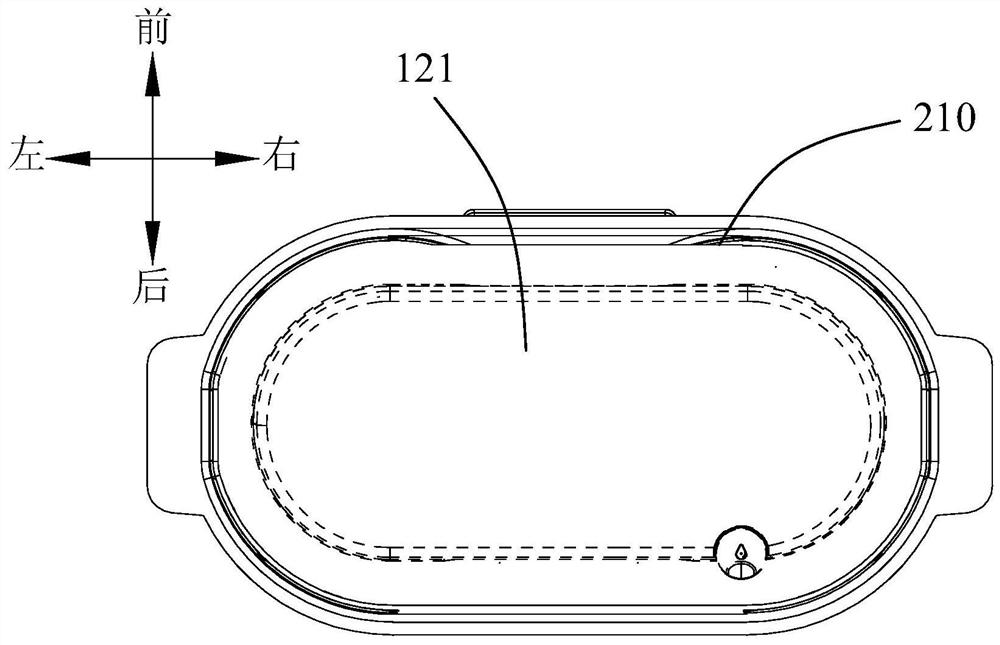

[0043] In this embodiment, the horizontal limiting member cooperates with the housing of the cleaning head 120 to make the cleaning head swing horizontally back and forth in the cleaning tank. Specifically, the housing 121 of the cleaning head includes a front side wall 121a and a rear side wall 121b, and the cleaning tank 210 includes a front side wall 210a and a rear side wall 210b.

[0044] In this way, the matching position of the horizontal limiter and the housing is relatively higher than the scraping surface of the wiper and the cleaning member, preventing the cleaning head from detaching from the cleaning tank, so that the cleaning head is more stable when it swings horizontally in the cleaning tank ,

[0045] In an implementation manner of this embodiment, the horizontal limiting member is a side wall of a cleaning tank. Since the side wall of the cleaning tank defines the cleaning space in the cleaning tank, by setting the side wall of the cleaning tank as a horizon...

Embodiment 2

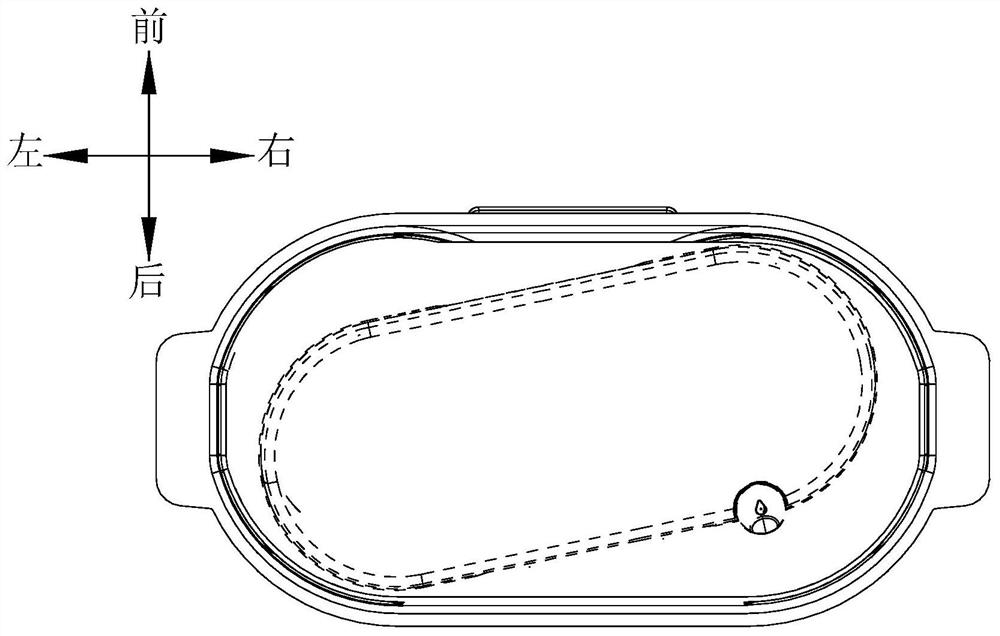

[0058] combined with Figure 8 , 9 As shown, the difference between this embodiment and Embodiment 1 is that: the horizontal limiting member cooperates with the turntable to make the cleaning head reciprocate horizontally in the cleaning tank.

[0059] Preferably, the horizontal limiting member is a limiting column 211a, which is arranged on the cleaning member 211 and there are two in number, and the bottom of the turntable 122 is provided with a limiting column corresponding to the limiting column 211a. Groove (not shown in the figure), when the surface cleaning device is placed in the cleaning tank, the limiting post extends into the limiting groove for cooperation, so that the cleaning head swings horizontally back and forth in the cleaning tank.

Embodiment 3

[0061] The difference between this embodiment and Embodiments 1 and 2 is that the cleaning assembly in this embodiment also includes a rotatable valve stem 230, the valve stem 230 is at least partly arranged in the cleaning tank, and the valve stem 230 includes a driving end 231 and driven end 232, the bottom of the cleaning chamber is provided with a sewage outlet 213, the driven end 232 of the valve stem 230 is provided with a valve body for closing the sewage outlet 213, the driving end 231 of the valve stem 230 is in contact with the mop, and the turntable turns When rotating, the mop drives the valve rod 230 to rotate to open the sewage outlet 213 . Specifically, in this embodiment, the turntable on the left side of the cleaning head is set corresponding to the valve stem 230, and when the turntable on the left side of the cleaning head is reversed, the mop drives the valve stem 230 to rotate to open the sewage outlet 213, When the turntable on the left side of the cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com