Induction heating pickling tank

An induction heating and induction heating coil technology, applied in the field of pickling tanks, can solve the problems of slow heating speed, short service life, serious energy consumption, etc., and achieve the effects of easy temperature, long service life and good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

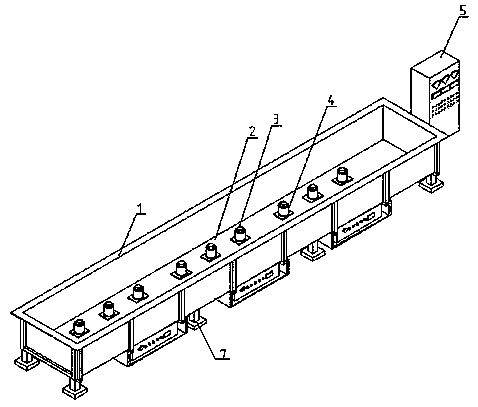

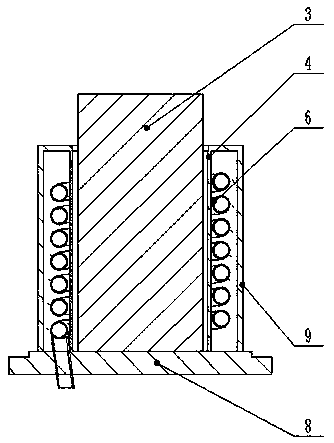

[0026] The reference signs in the accompanying drawings include: pickling tank 1, bottom plate 2, heating block 3, inner casing 4, AC control cabinet 5, induction heating coil 6, support base 7, mounting plate 8, outer casing 9.

[0027] A kind of induction heating pickling tank in this specific embodiment, as figure 1 and figure 2 As shown, it includes a non-metallic pickling tank 1, the non-metallic pickling tank 1 is a rectangular tank body with an upper opening, the tank body includes a horizontal bottom plate 2 and vertical side plates, and the upper surface of the bottom plate 2 is along its length A plurality of vertically extending outer sleeves 9 are provided at the distance between directions, and an inner sleeve 4 that is concentric with the centerline and spaced apart from the outer sleeve 9 is arranged inside the outer sleeve 9. Both the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com