A Finned Small Channel Parallel Tube Heat Exchanger and Its Calculation Method

A technology of parallel pipelines and heat exchangers, applied in indirect heat exchangers, heat exchanger types, heat exchange simulation, etc. Insufficient effect and other problems, to achieve the effect of improving the heat exchange effect outside the tube, making up for the adverse effect, and improving the performance of the heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the utility model is further elaborated:

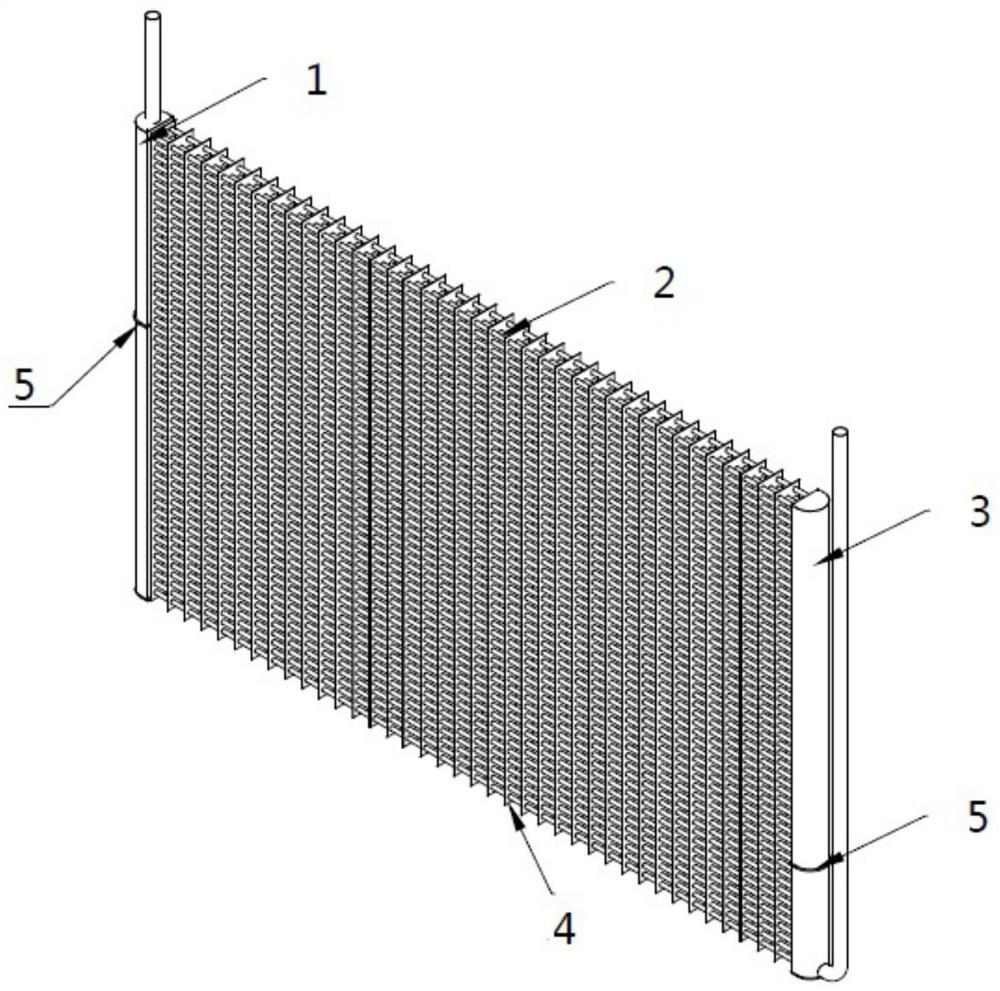

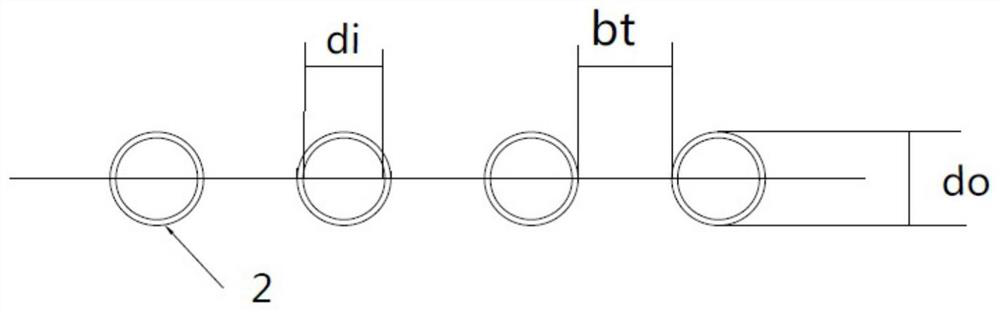

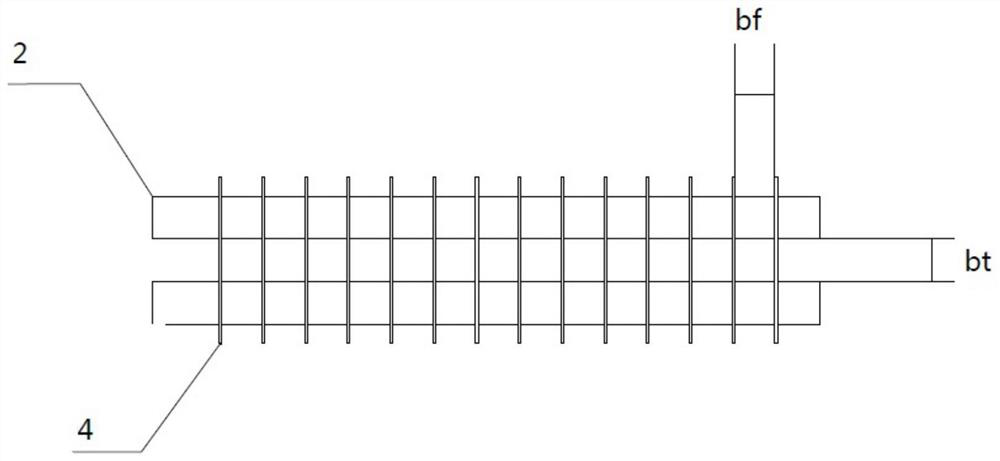

[0029] see Figure 1 to Figure 5 As shown, a finned small channel parallel pipe heat exchanger includes an inlet pipe 1, a parallel pipe 2 and a discharge pipe 3. The parallel pipe 2 communicates with the inlet pipe 1 and the discharge pipe 3 respectively, and the parallel pipe Fins 4 are arranged on the road 2, and the parallel pipes 2 are arranged in at least one row, and when the outer diameter of the parallel pipes 2 is d o The value range is 1mmo ≤3.95mm, the heat transfer capacity of the heat exchanger and the structure of the heat exchanger conform to the following formula:

[0030]

[0031] Among them, Q is the heat transfer, the unit is W; C 0 is the error coefficient, the value is between 0.8 and 1.2; C 1 It is a constant value between 0.023 and 0.027; C 2 is a constant, the value is between 1.2 and 1.4; λ is the thermal conductivity of the medium outside the tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com