A temperature monitoring method of combined electric appliance based on fiber grating sensor

A combination of electrical appliances and optical fiber grating technology, applied in the direction of physical/chemical changes in thermometers, thermometers, thermometer parts, etc., can solve problems such as aging joints, melting deformation, insulation performance reduction, etc., and achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment discloses a method for monitoring the temperature of an optical fiber grating for a combined electrical appliance. The method includes the following steps:

[0023] S01), pre-stretching the temperature-measuring fiber grating and encapsulating it in the base material for sensitization to form a fiber grating sensor. After the encapsulation is completed, the residual stress is eliminated by changing the temperature. The base material has a high thermal expansion coefficient and stable thermophysical properties. Fiber compatibility is high;

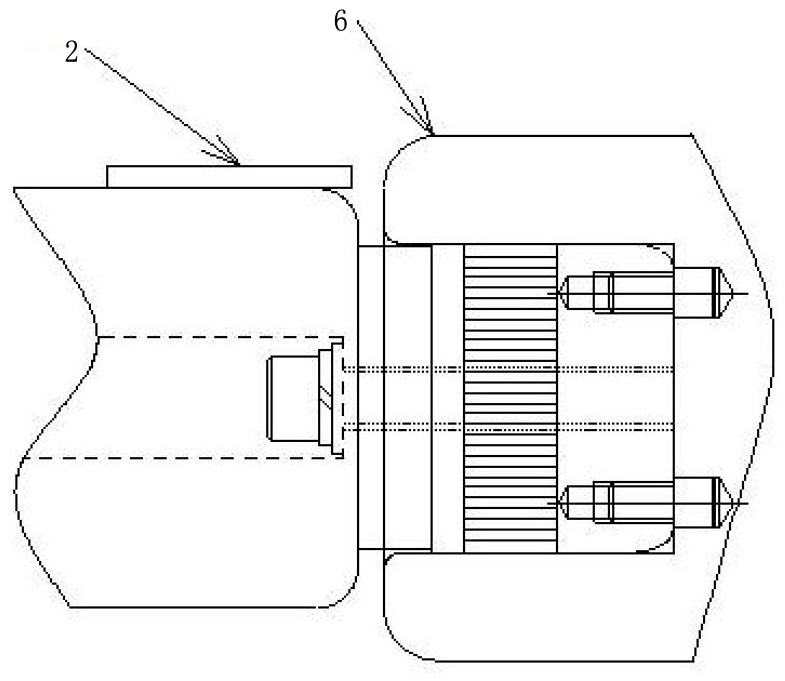

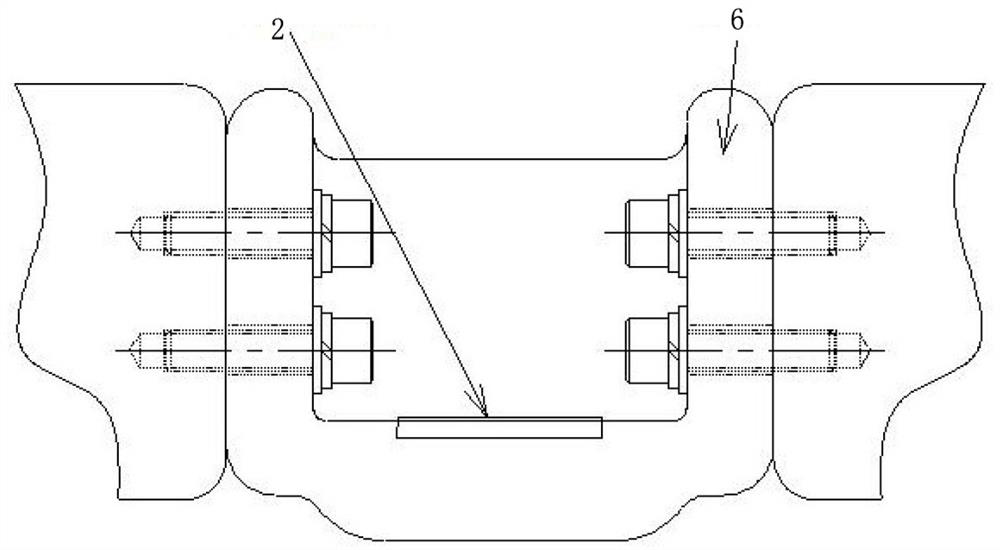

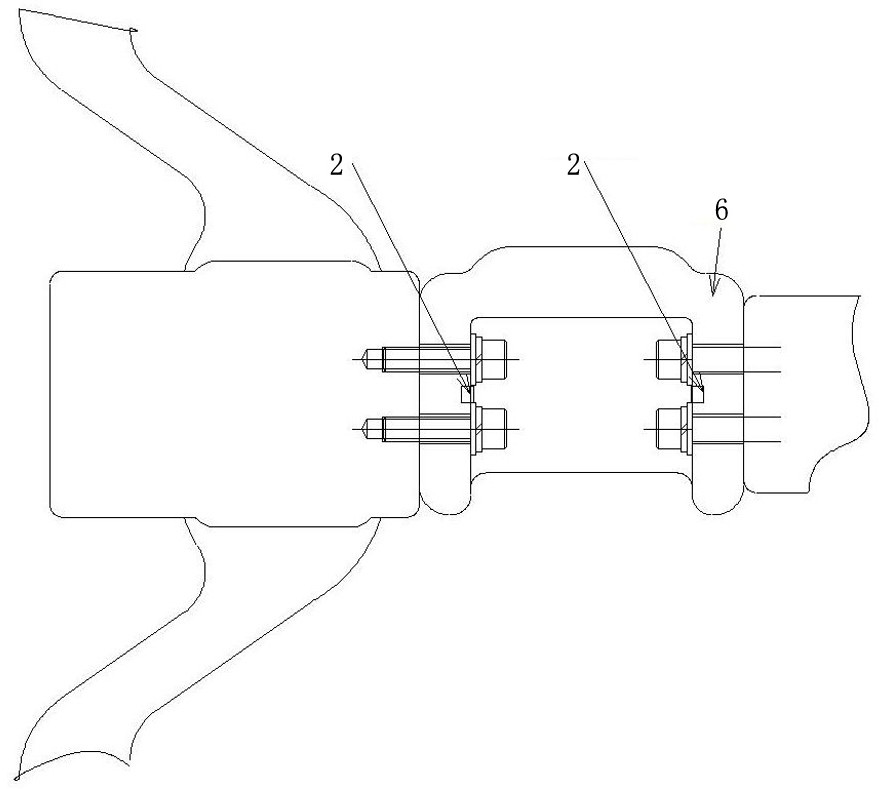

[0024] In this embodiment, the optical fiber grating sensor 2 is used to collect the temperature information of the internal joints of the combined electrical appliance. The thermal expansion effect and the thermo-optic effect of the optical fiber grating sensor will occur due to the change of the external environment temperature. The grating period change caused by the thermal expansion effect is: ΔΛ= α·Λ·ΔT, Λ is th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com