Food air-drying device

An air-drying device and food technology, applied in food preservation, food science, application, etc., can solve the problems of low air-drying rate and incomplete air-drying, and achieve the effect of ensuring quality and production and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] Example 1

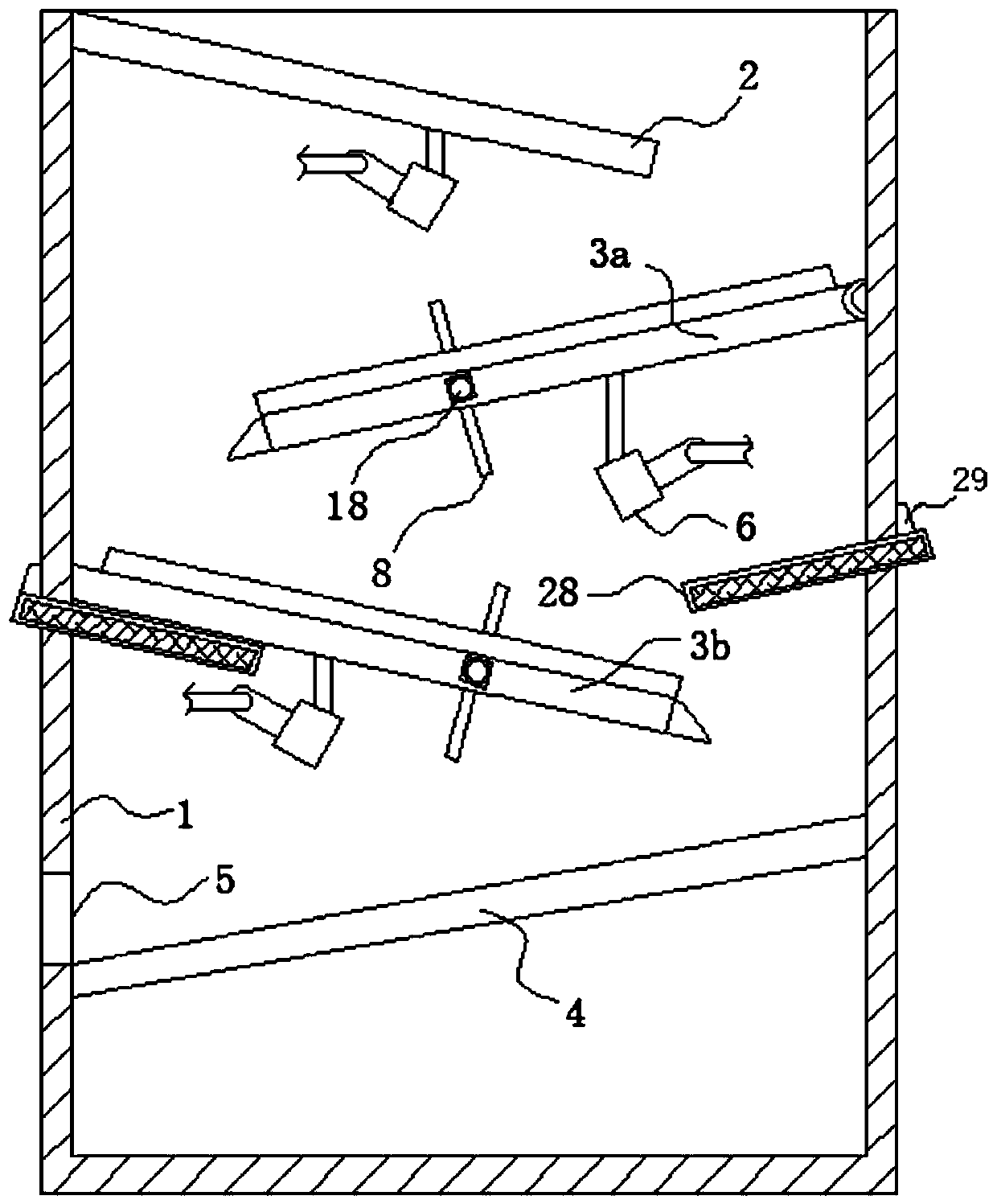

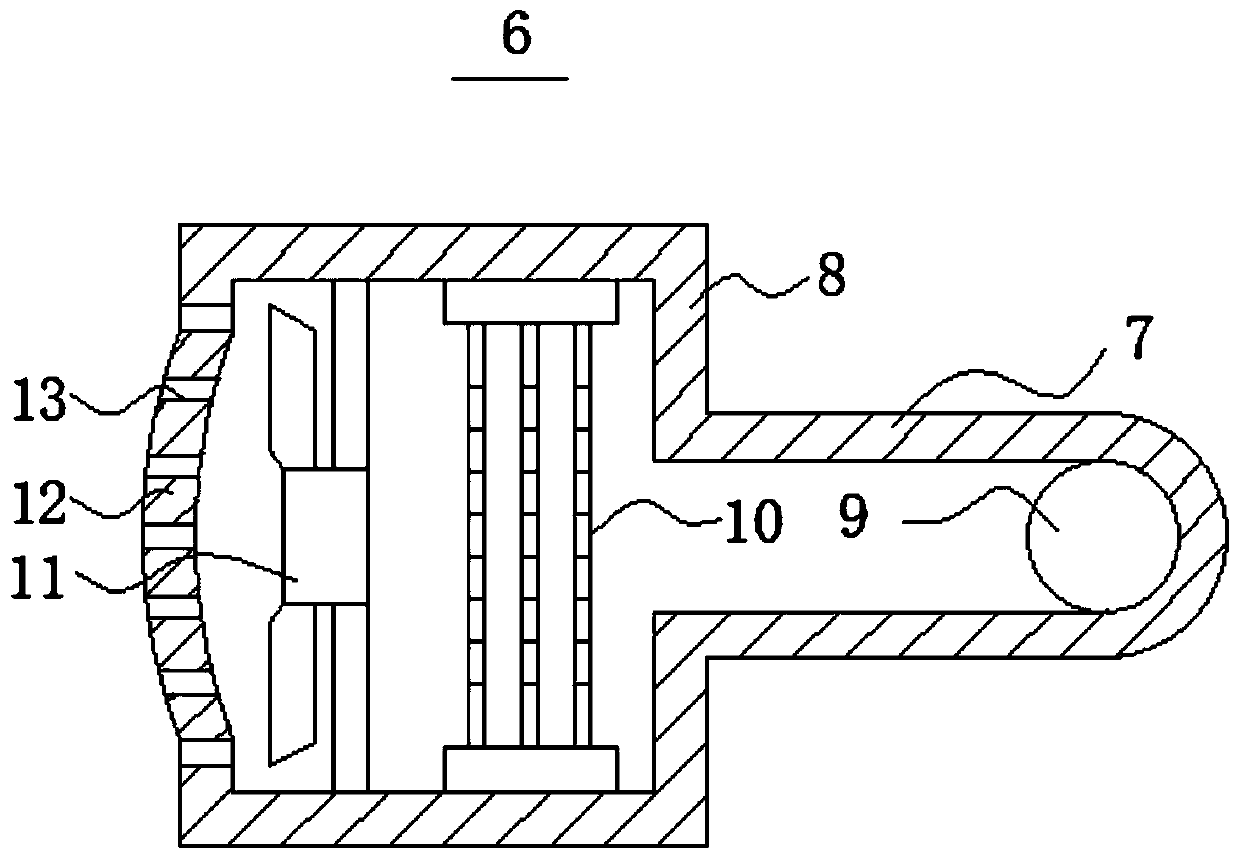

[0028] Please combine Figure 1 to Figure 4 , The food air-drying device includes a housing 1 with an open top. A discharge port 5 is opened on one side of the housing 1. The discharge port 5 is used for the discharge and collection of dried plate-shaped food. The specification of the discharge port 5 can be Design or select according to actual needs. The inside of the housing 1 is staggered from top to bottom with a downwardly inclined guide plate 1, rail 1 3a, rail 2 3b, and guide plate 2 4. The inclination direction of rail 1 3a is opposite to that of rail 2 3b, and rail 1 3a Parallel to guide plate two 4, rail two 3b parallel to guide plate one 2, the lower end of guide plate two 4 in the vertical direction points to the discharge port 5 and is connected to the housing 1 at the discharge port 5. The corresponding inner wall is connected. In this embodiment, the higher end of the guide plate 2 is flush with and connected to the inner wall of the opening a...

Example Embodiment

[0041] Example 2

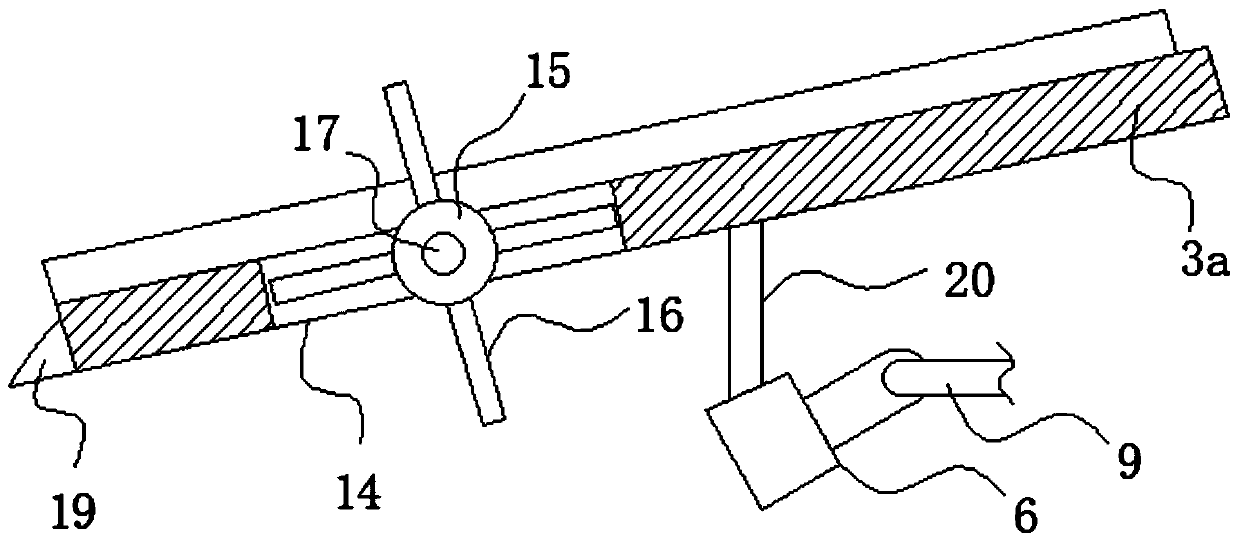

[0042] Please combine Figure 5 This embodiment 2 is an improved solution of embodiment 1. The higher end of the track 1 3a in the vertical direction is rotatably connected with the corresponding inner wall of the housing 1, and the track 3a and the inner wall of the housing 1 are rotated by a pin. connection. The inner wall of the housing 1 under the guide plate 2 is provided with a sliding groove 22 perpendicular to the rail one 3a. The sliding groove 22 is slidably connected with a sliding block 23. The bottom end of the sliding block 23 is connected to the rail one 3a through a connecting rod 24. The side of the lower end is pivotally connected in the vertical direction. The connecting rod 24 and the sliding block 23 are fixedly connected, and the connecting rod 24 and the track 3a are rotationally connected by a pin shaft.

[0043] The inner wall of the housing 1 on the side of the sliding groove 22 is provided with a rotating rod 26 perpendicular to the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com