A method and system for real-time evaluation of machine tool health status

A technology of health status and evaluation method, applied in the field of machine tool failure warning and health assurance, can solve problems such as poor anti-interference ability and poor machine tool physical examination results, and achieve the effect of improving accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

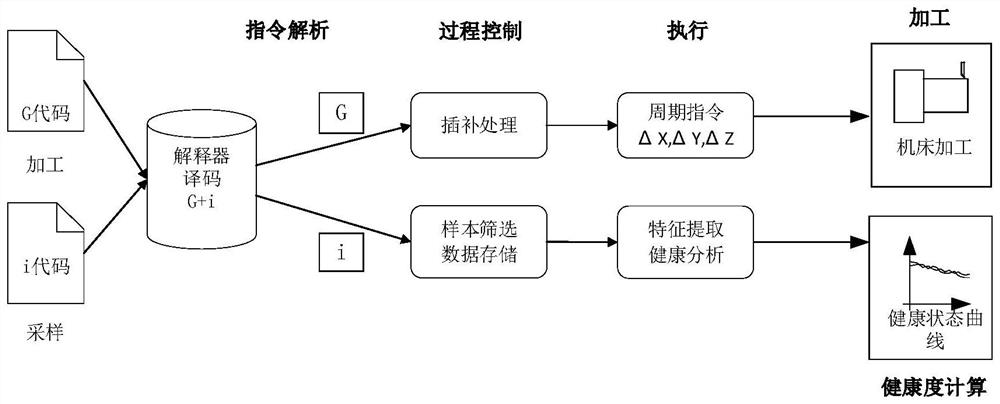

Method used

Image

Examples

specific Embodiment

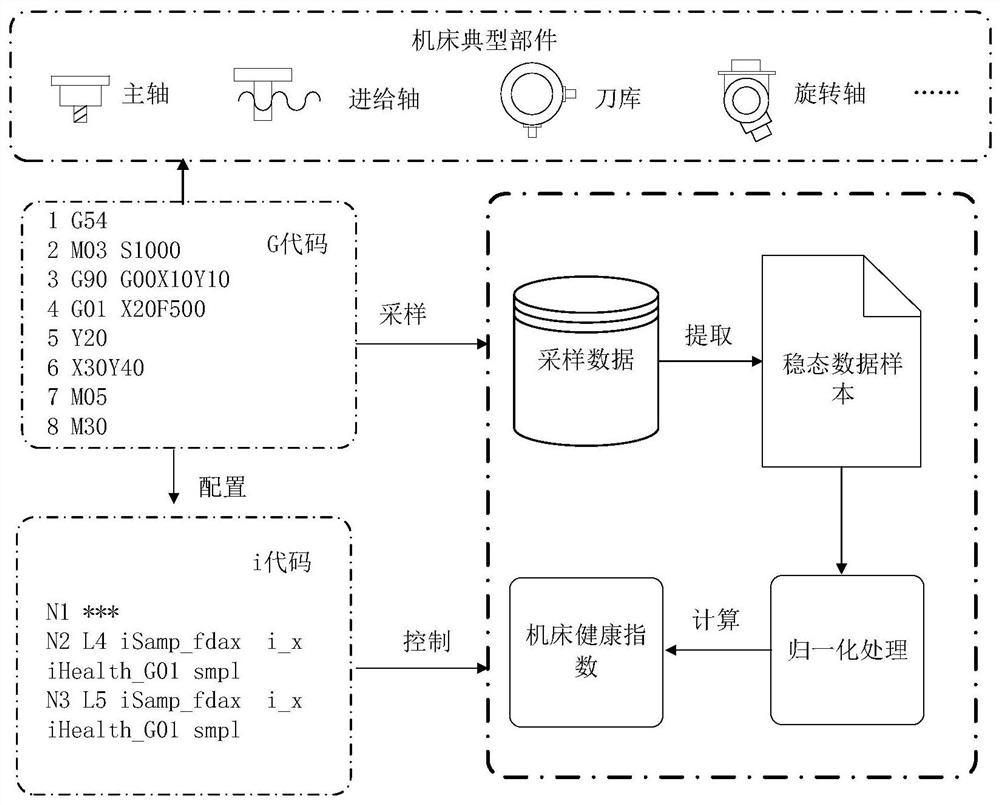

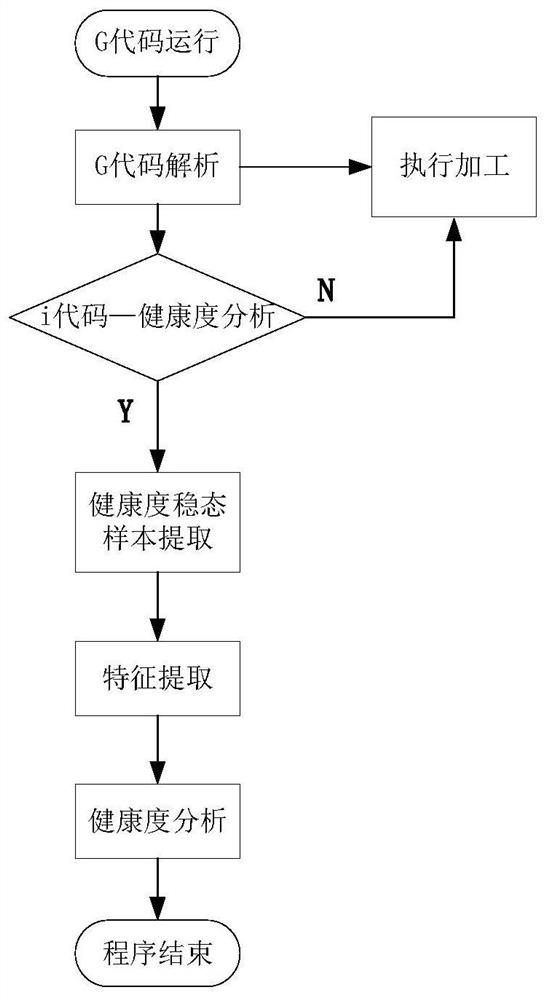

[0054] The health status evaluation of the spindle in the HNC8 CNC system includes the following steps:

[0055] S1. Run the machining G code, and the CNC system collects the electrical control data of the machine tool spindle in the non-cutting process by the fixed-point sampling method according to the configured self-check i command as a steady-state sample;

[0056] S2. Extract the characteristic index from the steady-state sample (take a sampling point as an example), as shown in Table 1:

[0057] Table 1

[0058]

[0059] Express the result in the form of a vector, that is, the feature index X h =(0.9995,21.4,12.8,1004,21);

[0060] S3. Since some characteristic indicators are affected by servo control parameters, parameterization is required to eliminate the influence. For example, the spindle speed change rate of the spindle servo parameters of the machine tool is a=2000r / (min*s). Remove the working conditions according to the formula, and get the characteristic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com