Thick cup punching underwear technological process

A technological process and underwear technology, applied in underwear, baby underwear, corsets, etc., can solve the problems of impermeable aperture, exposed air hole, deformation of hole surface, etc., to ensure air permeability, air permeability effect, and smooth surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

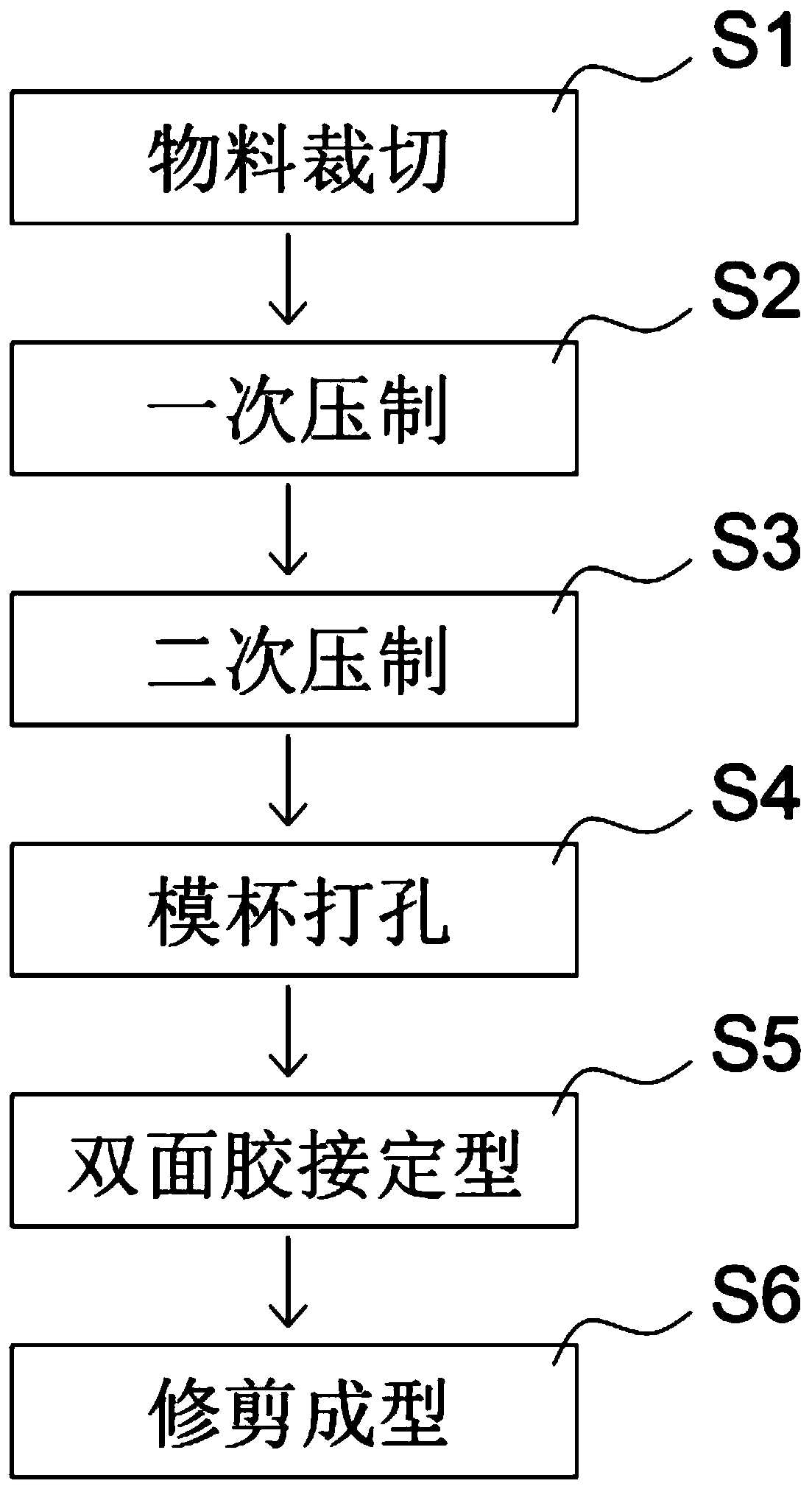

[0028] Such as figure 1 As shown, including the preparation of materials and auxiliary materials, the following steps are also included:

[0029] S1: Cut the material into the required size and shape;

[0030] S2: Pressing a layer of primer sponge for the first time;

[0031] S3: Glue the pressed bottom material sponge and place the cotton pad and fabric sponge for the second pressing to form the inner liner of the mold cup;

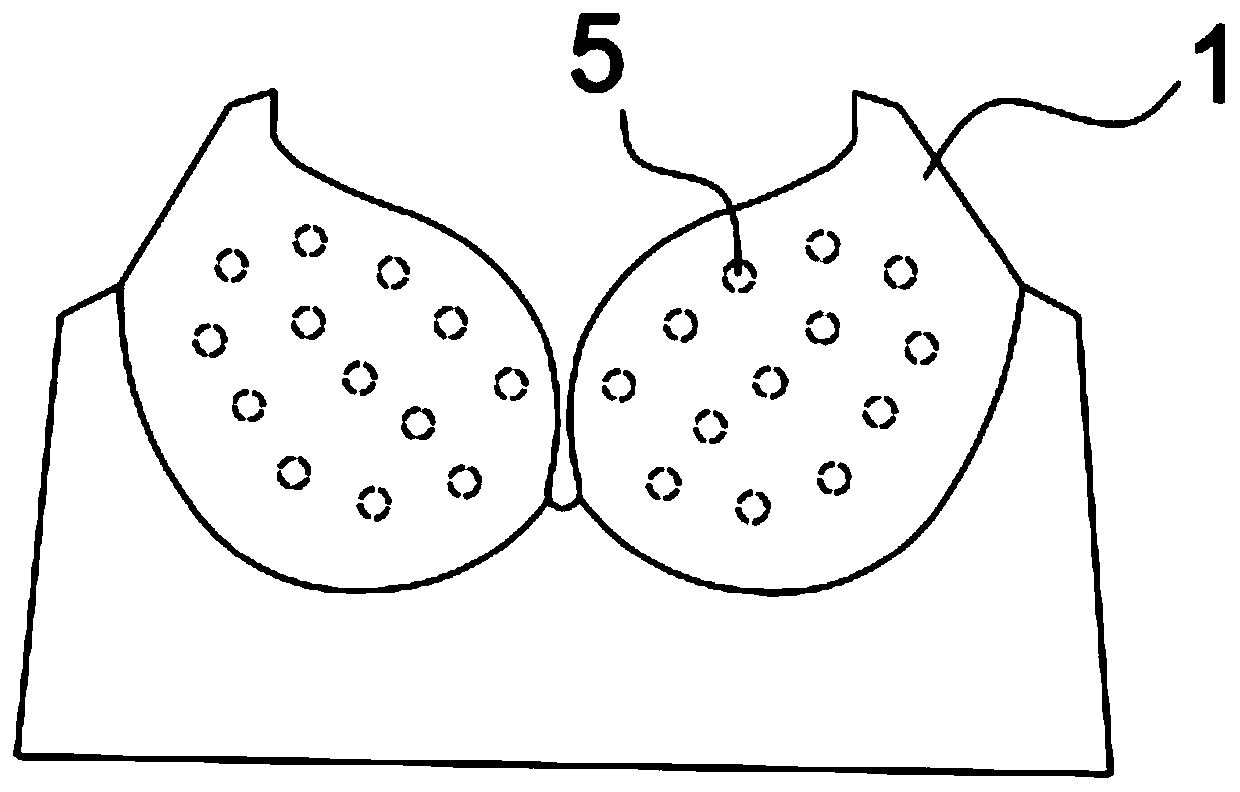

[0032] S4: Perforating the inner liner of the mold cup;

[0033] S5: Spray glue on both sides of the holed mold cup liner, cover the inner and outer sides with the bottom fabric and surface fabric respectively and shape it;

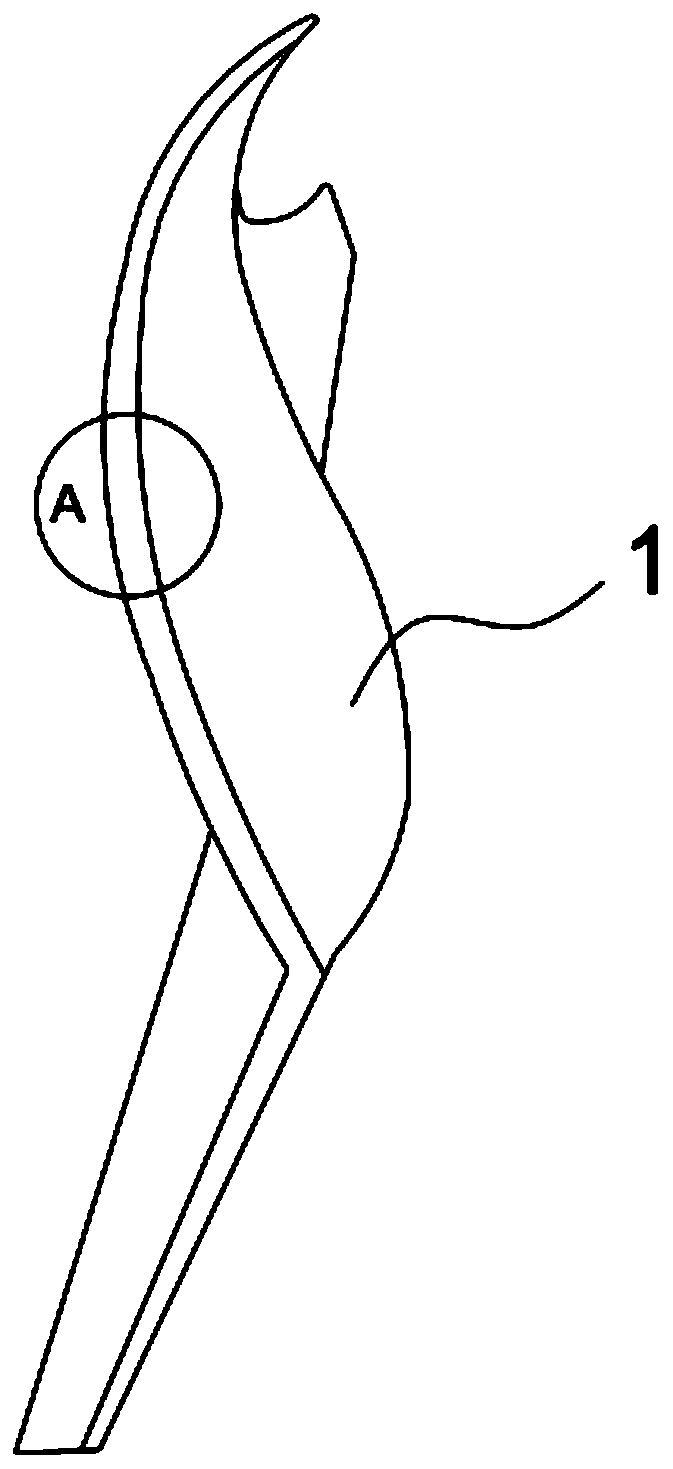

[0034] S6: Heart out the molded cup and trim the excess to form a finished product.

[0035] The technical process of the thick cup perforated underwear of the present invention is to press and form the three-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com