A kind of production process and equipment of methallyl alcohol

A technology for methallyl alcohol and production equipment, applied in the field of production technology and equipment of methallyl alcohol, can solve problems such as low mixing efficiency, insufficient utilization of methane waste, waste of energy and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

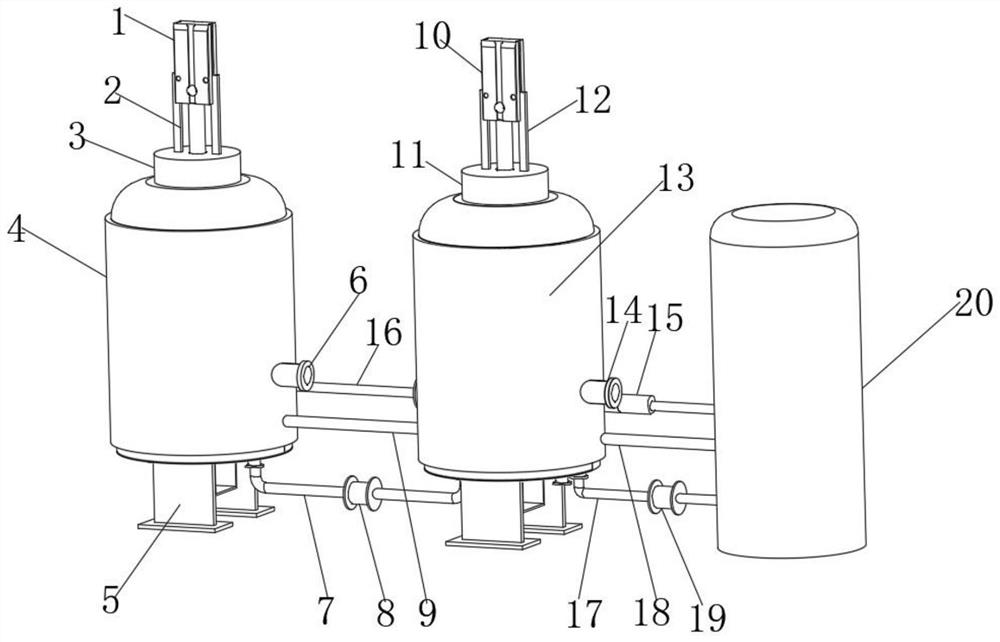

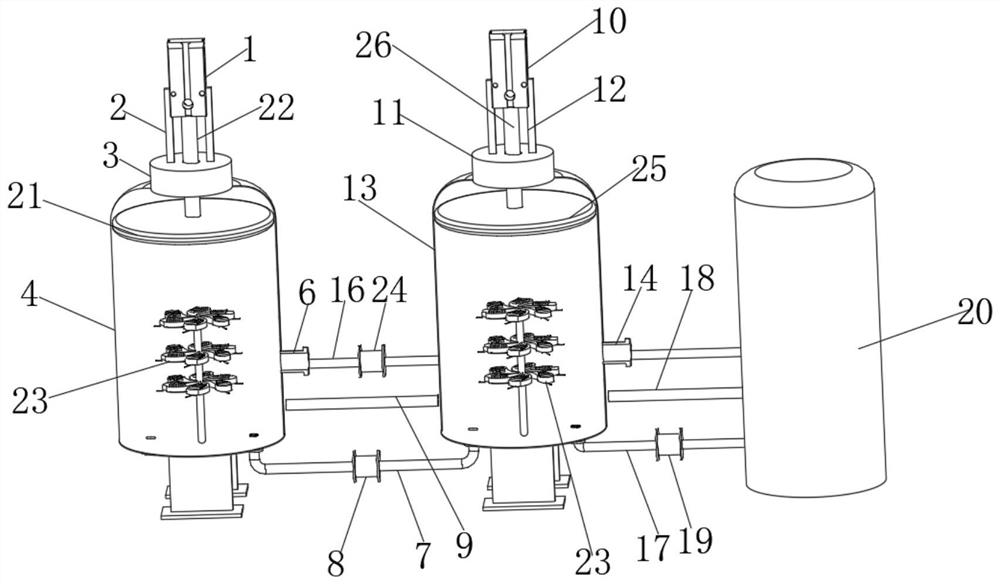

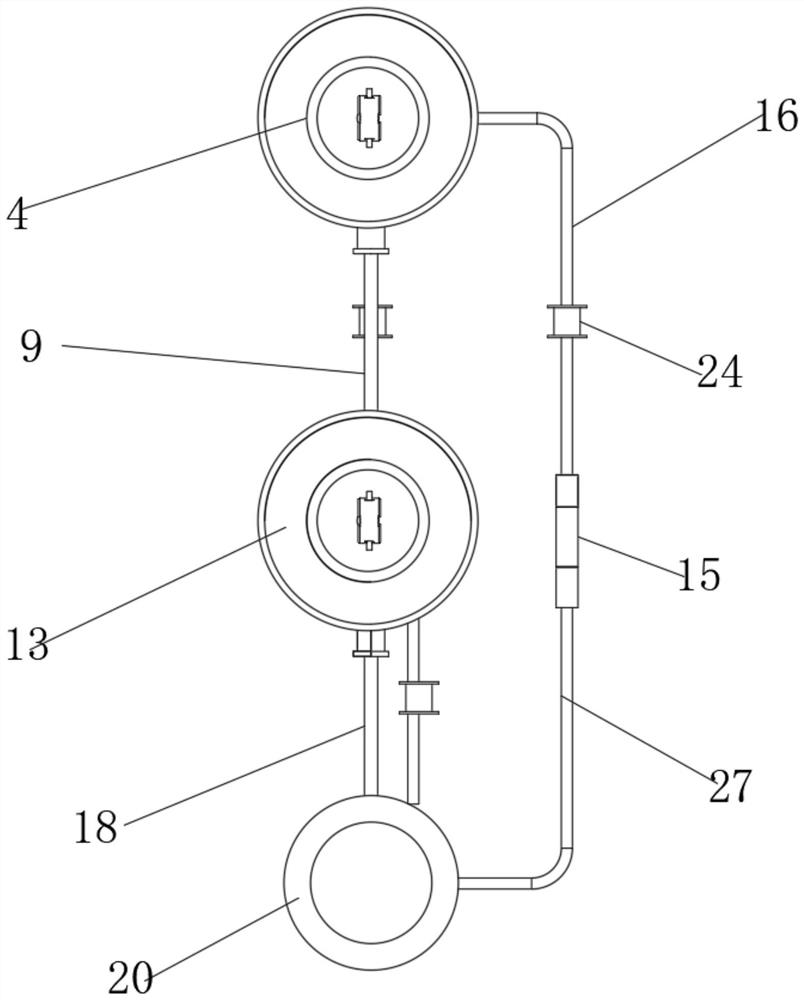

[0042] Such as Figure 1-Figure 10 As shown, the present embodiment discloses a production equipment for methallyl alcohol, including an oxygenation reactor 4, a first cylinder 1, a hydrogenation reactor 13 and an incinerator 20, and the oxygenation reactor 4 is provided with Stirring mechanism 23 is arranged, and described stirring mechanism 23 comprises stirring rod 2304, and the outer wall of described stirring rod 2304 is provided with several rotating blades 2302, and the upper surface of rotating blade 2302 is provided with evenly arranged scale lath 2301, and described The lower end of the stirring rod 2304 is connected with the output shaft end of the motor 30, the lower surface of the rotating vane 2302 is provided with a fixing part 2306, and the front and rear sides of the fixing part 2306 are provided with chute 2307, and the slide groove 2307 slides A sliding piece 2308 is connected, and one side of the sliding piece 2308 is provided with a branch leaf 2303 perpen...

Embodiment 2

[0052] This embodiment discloses a production process of a production equipment for methacryl alcohol, said process comprising the following steps:

[0053] S1: Put the prepared isobutylene into the oxygenation reactor 4, then connect the oxygen delivery pipe to the oxygenation nozzle 6, produce methacrolein, acetone and methacrylic acid after the reaction, and the isobutylene and oxygen are mixed in the oxygenation reactor through the above steps Fully mix in the oxygenation reactor 4, then separate methacrolein from the remaining acetone and methacrylic acid, and then conduct concentrated biochemical treatment of acetone and methacrylic acid, and the clean products produced after the treatment include carbon dioxide, water and methane , methane can be put into the incinerator 20 for utilization, while water and carbon dioxide are cleanly collected and used, so that the waste gas produced in this way can be fully utilized, and at the same time, it is more environmentally frien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com