Radial porous fogging 3D printing leadless piezoelectric ceramic atomizing piece

A piezoelectric ceramic chip, lead-free piezoelectric technology, applied in the direction of injection device, liquid injection device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments: this embodiment is only a basic embodiment of the present invention, rather than all embodiments.

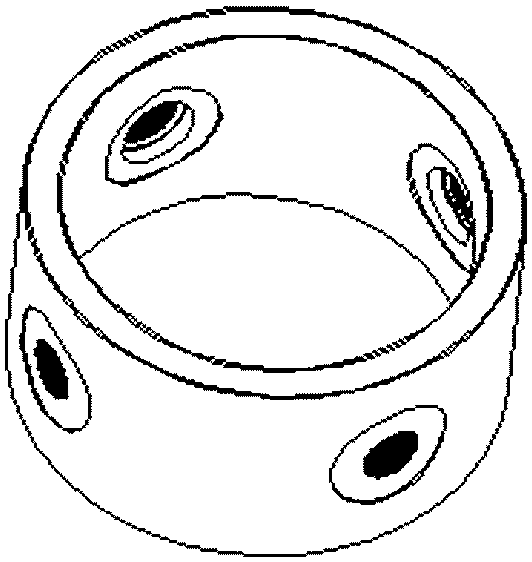

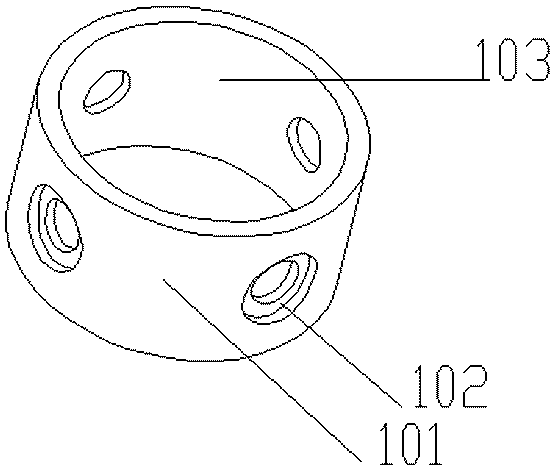

[0037] Such as figure 1 As shown, a radially porous 3D printed lead-free piezoelectric ceramic atomizer, the lead-free piezoelectric ceramic atomizer is made of potassium sodium niobate-based lead-free piezoelectric ceramic.

[0038] The piezoelectric ceramic sheet is circular, with 4 radial grooves, such as figure 2 As shown, the outer diameter of the ring is 60mm and the inner diameter is 52mm.

[0039] The diameter of the through hole of the groove of the piezoelectric ceramic sheet is 10mm, and the diameter of the groove is 16mm.

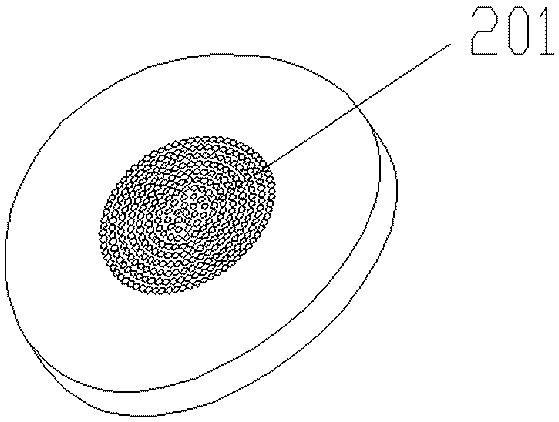

[0040] The metal sheet is circular, such as image 3 As shown, the diameter is 16mm.

[0041] The thickness of the metal sheet is 0.2mm.

[0042] The atomization hole structure of the metal sheet is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com