A multi-angle flattening device for processing decorative panels

A decorative board and multi-angle technology, applied in the field of multi-angle flattening devices, can solve the problems that the flatness cannot be guaranteed, the decorative board is prone to repetition, and the pressing force is difficult to control, so as to ensure the appearance and smooth performance, ensure the pressing force. Flat effect, ensure the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

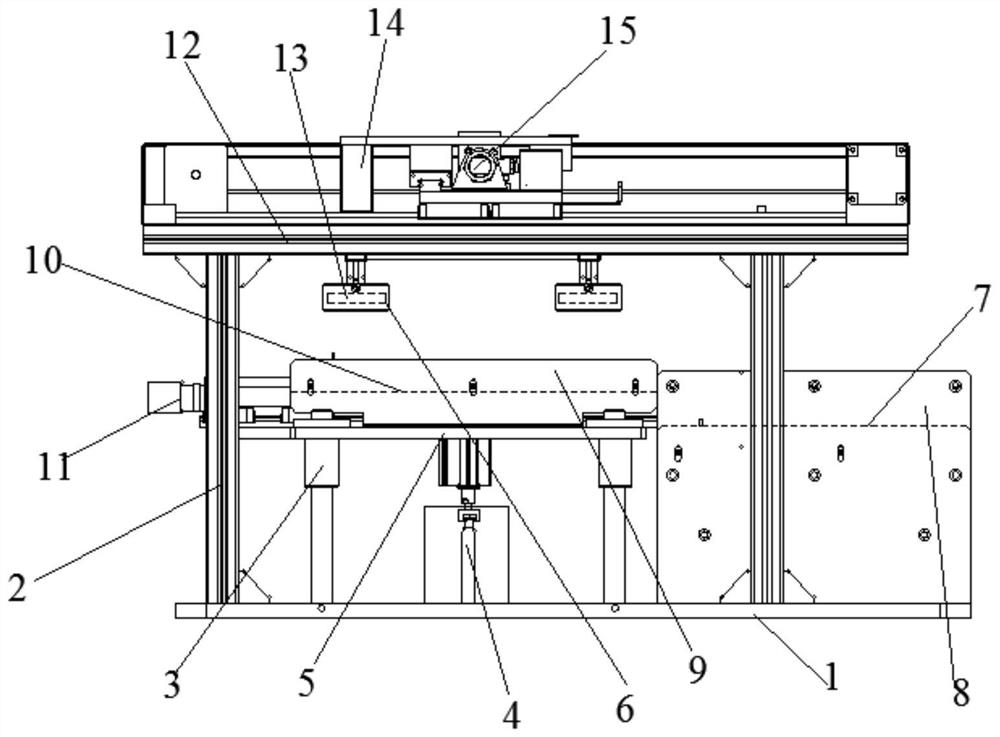

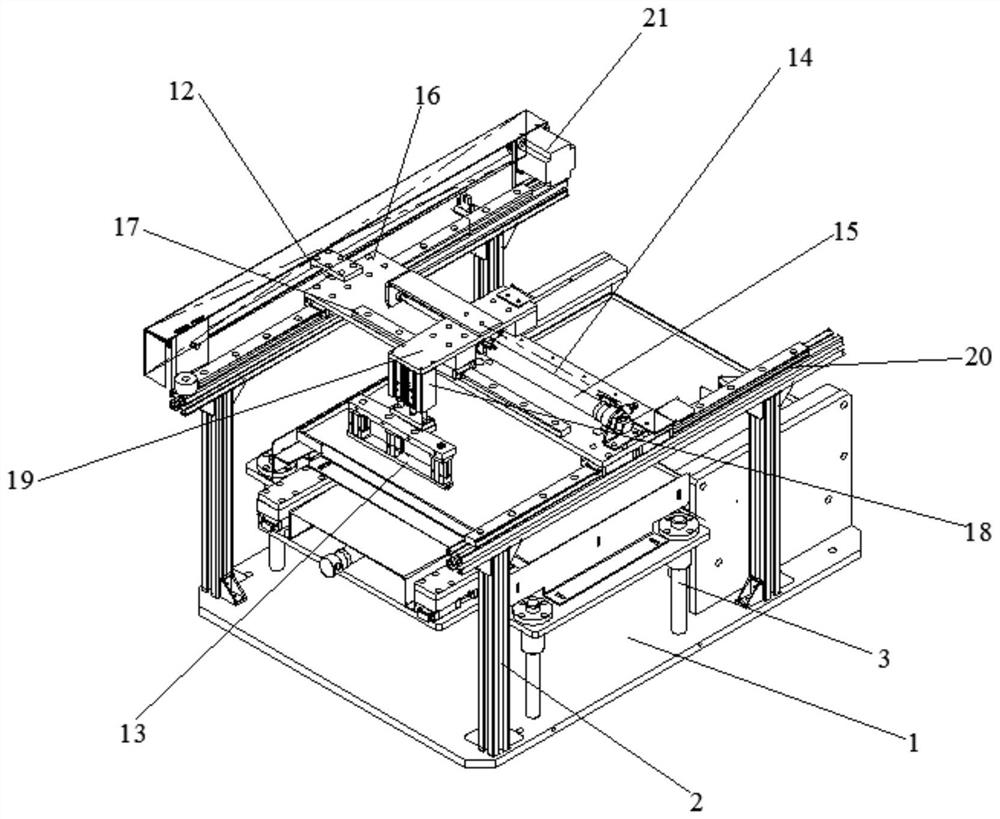

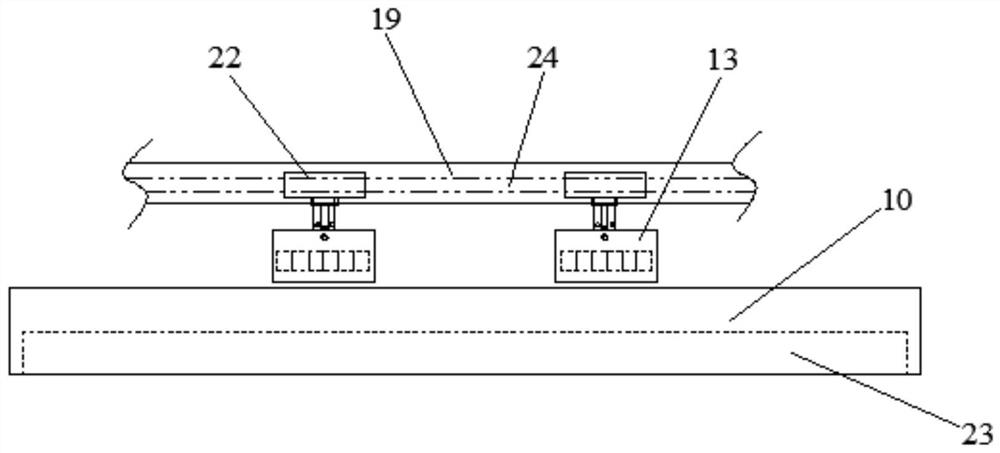

[0024] see Figure 1~5 , in an embodiment of the present invention, a multi-angle flattening device for decorative panel processing, which includes a bottom plate 1, a bracket 2, a feeding table 7, a flattening processing table 10, a lateral support beam 12, a lateral moving seat 14, The longitudinal moving seat 19 and the flattening block 13, wherein, the support on the base plate is provided with two horizontally extending horizontal support beams, and the horizontal reciprocating movement on the two transverse support beams is provided with a transverse moving seat, The longitudinally movable seat is provided with the longitudinal movable seat on the said transversely movable seat, and two said flattening blocks which can move laterally and can be lifted symmetrically are arranged on the said longitudinally moving seat, and said flattening block A liftable flattening processing platform is provided below the flattening processing platform, and a feeding platform fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com