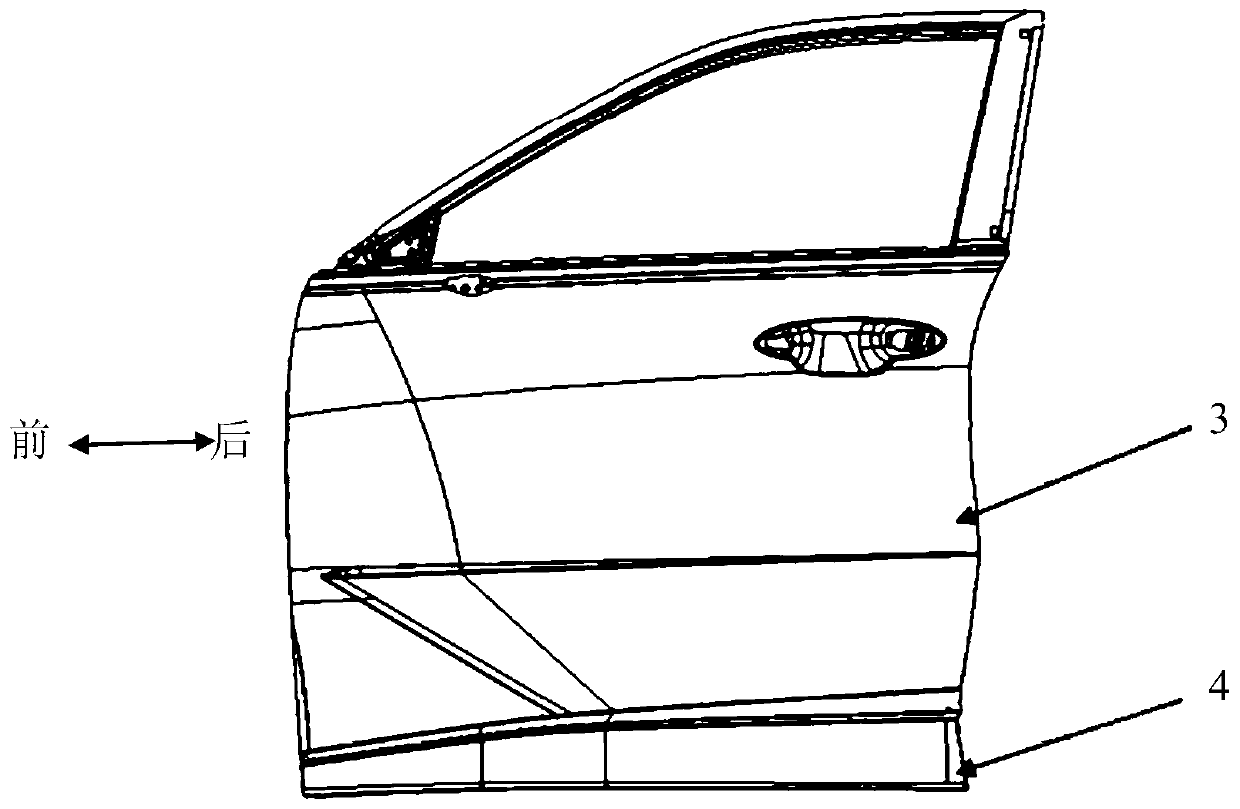

Vehicle door sill system

A door and threshold technology, applied in the direction of doors, vehicle parts, superstructure, etc., can solve the problems of difficult stamping and forming of sheet metal inside the door, the height of the outer trim panel is shortened, and the depth is increased, so as to achieve full package sealing, increase The effect of improving connection strength and freedom of modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

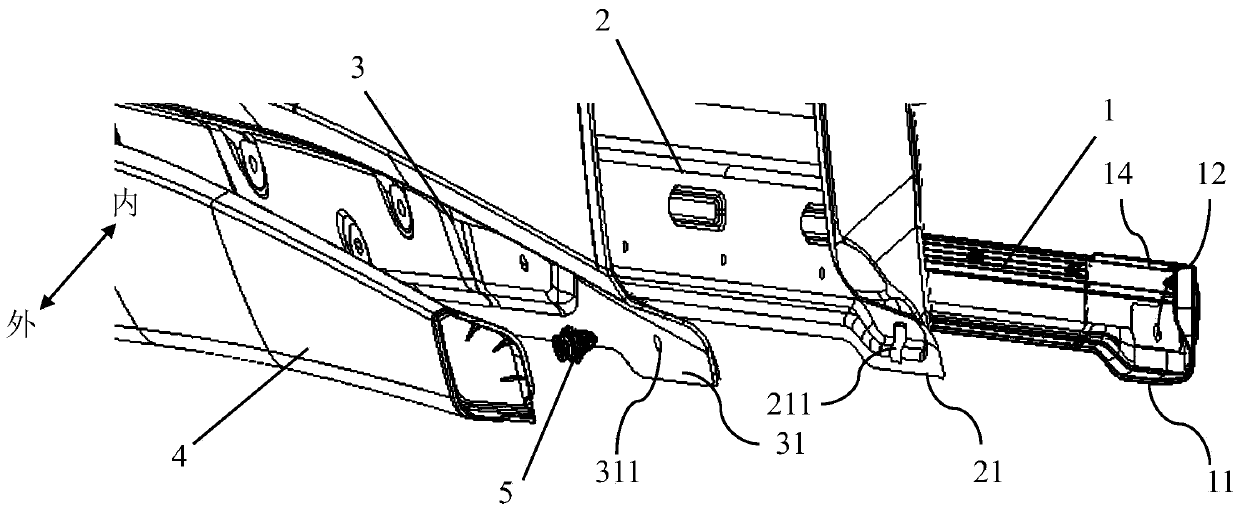

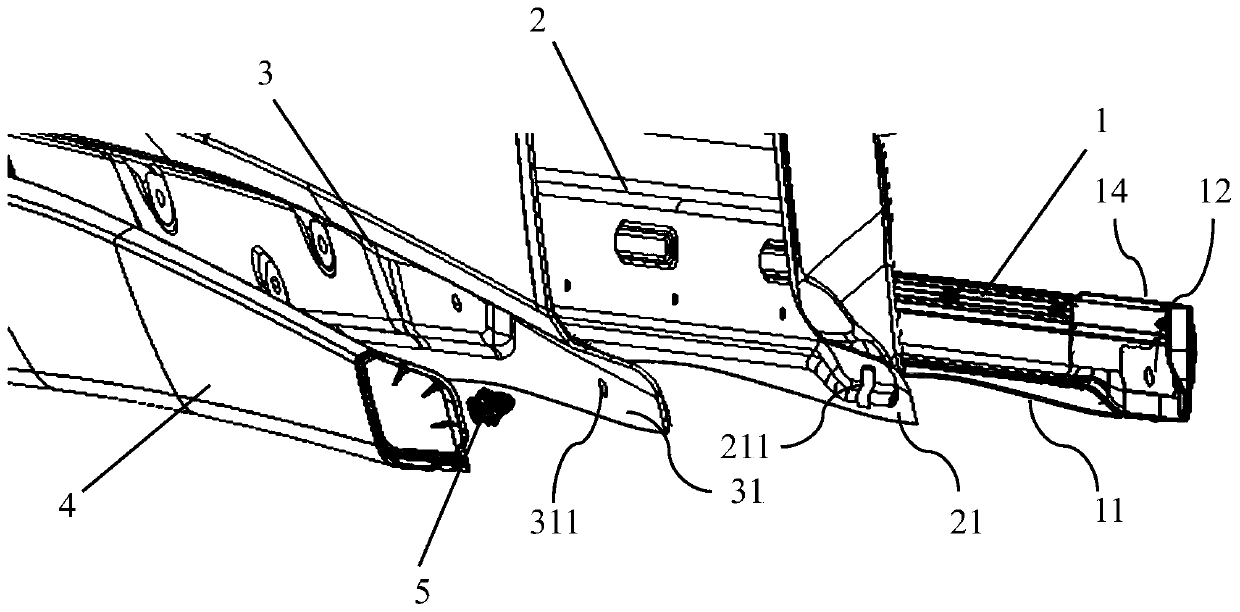

[0040] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

[0041] It is easy to understand that, according to the technical solution of the present invention, there are multiple structural modes and implementation modes that can be replaced by one of ordinary skill in the art without changing the essential spirit of the present invention. Therefore, the following specific embodiments and drawings are only exemplary descriptions of the technical solutions of the present invention, and should not be regarded as all of the present invention or as a limitation or limitation to the technical solutions of the present invention.

[0042] The directional terms such as up, down, left, right, front, back, front, back, top, bottom, etc., mentioned or may be mentioned in this specification are defined relative to the structure shown in the drawings, and they are The concept of relative, therefore, may change accordingly accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com