condenser

一种冷凝器、制冷剂的技术,应用在蒸发器/冷凝器、制冷机、制冷组件等方向,能够解决制造成本增大、阻碍应用、冷凝器、收集器和过冷器复杂等问题,达到避免重新加热、提高系统性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

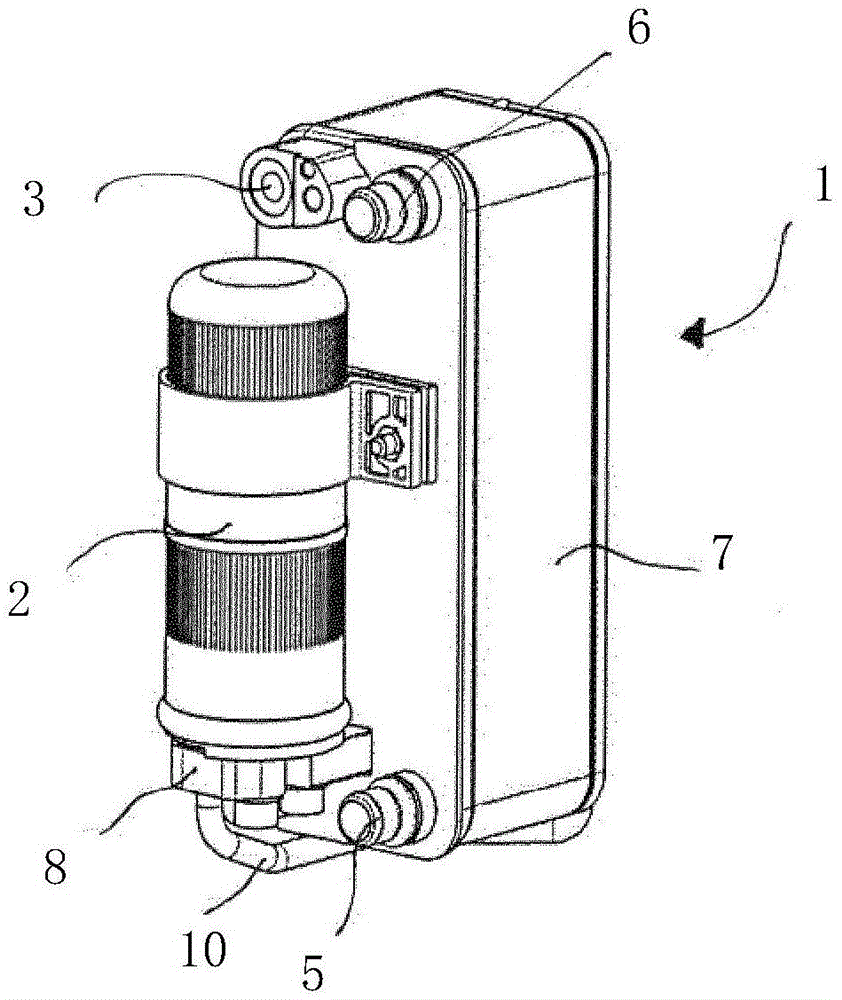

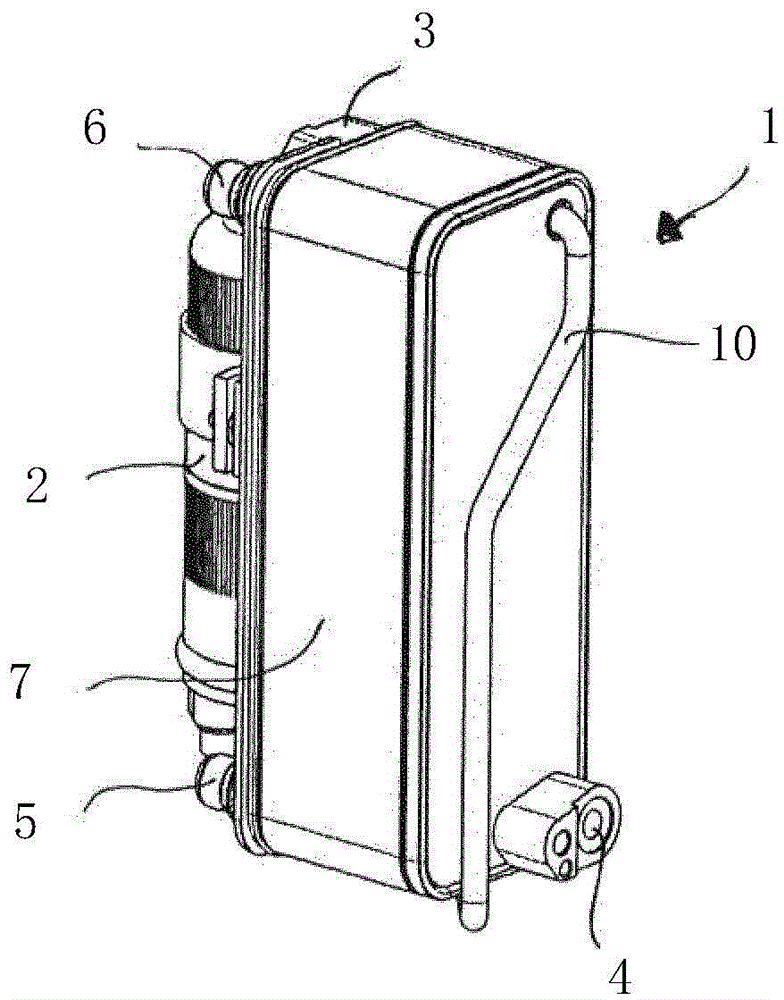

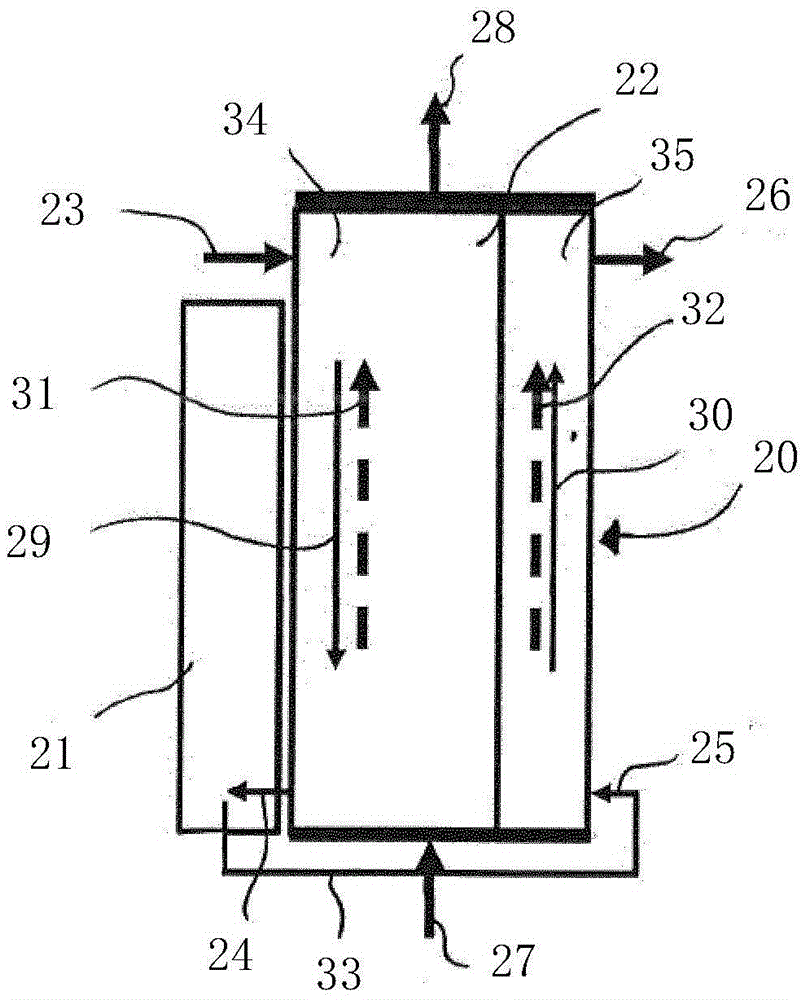

[0051] figure 1 A perspective view of the condenser 1 with stacked plate structure is shown. The condenser 1 is formed here from a plurality of individual plate elements which are stacked on top of each other to form a heat exchanger module 7 . The heat exchanger module 7 is designed in such a way that a plurality of channels are produced between the individual plate elements. Some channels are assigned to first flow channels through which refrigerant can flow. Other channels are assigned to second flow channels through which coolant can flow. Inside the heat exchanger module 7, the first flow channel is at least partially in thermal contact with the second flow channel, thus enabling heat transfer between the first flow channel and the second flow channel.

[0052] Through various configurations of the plate elements, a plurality of flow paths for the first and second flow channels can be formed within the interior of the heat exchanger module 7 . The fluid flowing throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com