Wheel carrier for multi-link axles for mounting on a motor vehicle

A multi-link, motor vehicle technology, applied in the direction of the cantilever, suspension, and vehicle parts installed on the pivot, can solve the problems of expensive manufacturing technology, improve the degree of freedom of modeling, reduce manufacturing costs, and high molding freedom degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the drawings, the same reference numerals are used for the same or similar components even when repeated description is omitted for the sake of simplification.

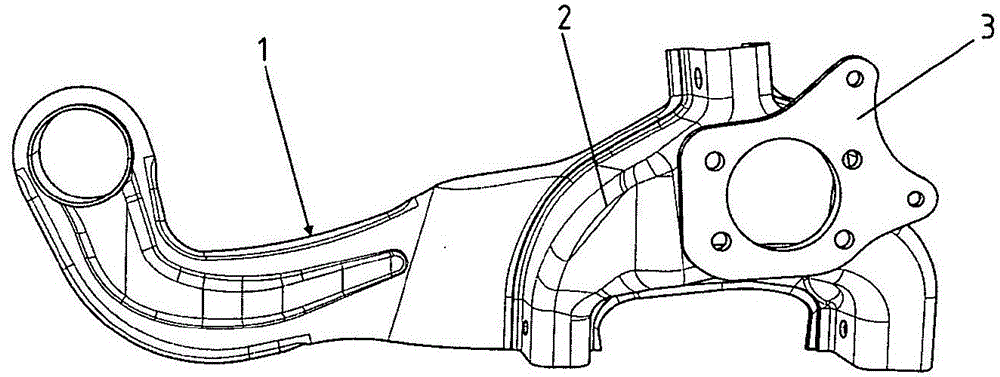

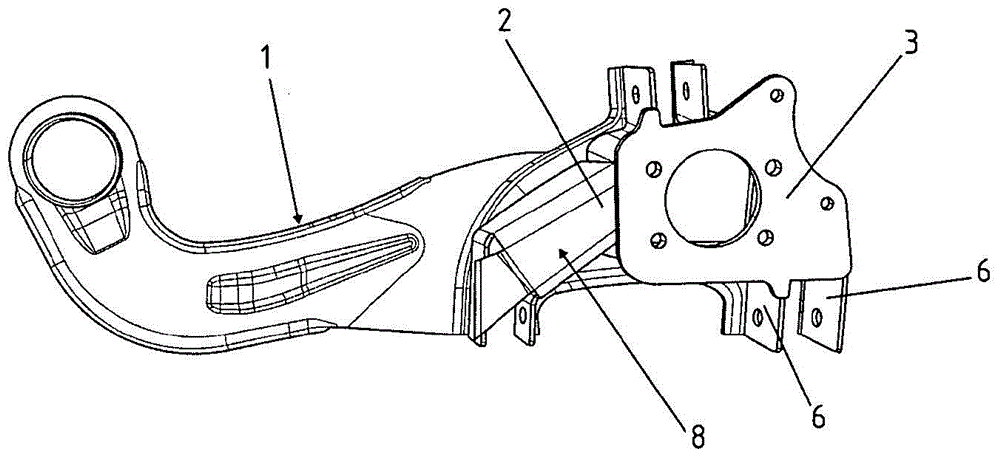

[0034] figure 1 A longitudinal link 1 and a wheel carrier 2 welded to the longitudinal link 1 are shown, wherein the wheel carrier 2 is formed as a single-shell profiled sheet metal component. Together with the wheel carrier 2 itself, a flange 3 in the form of a flange plate is again shown for coupling to a not further shown hub.

[0035] The wheel carrier 2 itself is coupled materially to the longitudinal link 1 by means of a welded connection, not shown further.

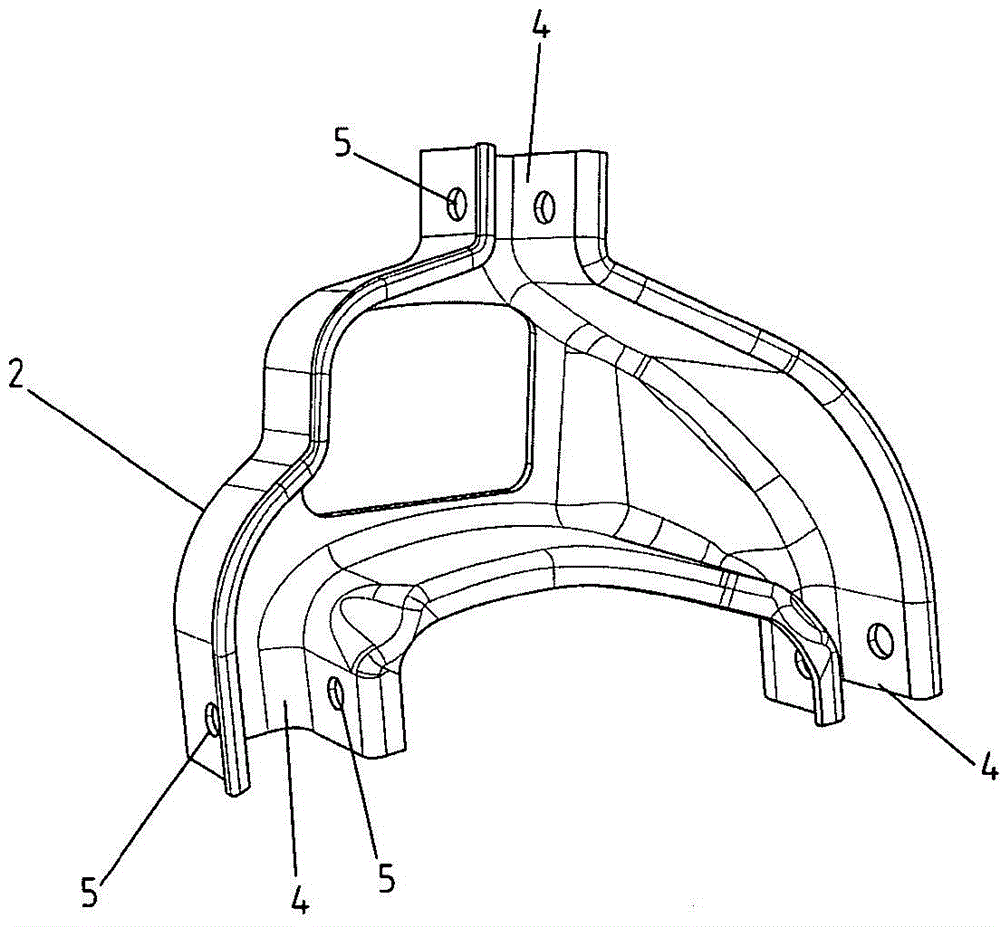

[0036] figure 2 The rear side of a wheel carrier 2 known from the prior art is shown, wherein three receptacles 4 are clearly formed, wherein a mounting opening is formed on each receptacle 4 on the left and on the right 5 serves to accommodate bolts, not further shown, so that a connecting rod, likewise not further shown, can be rotatably coup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com