High-speed railway track condition dynamic monitoring device

A technology for dynamic monitoring and high-speed railways, which is applied in the direction of railway vehicle shape measuring devices, railway car body parts, railway auxiliary equipment, etc. performance and comprehensive risk, and the effect of improving monitoring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

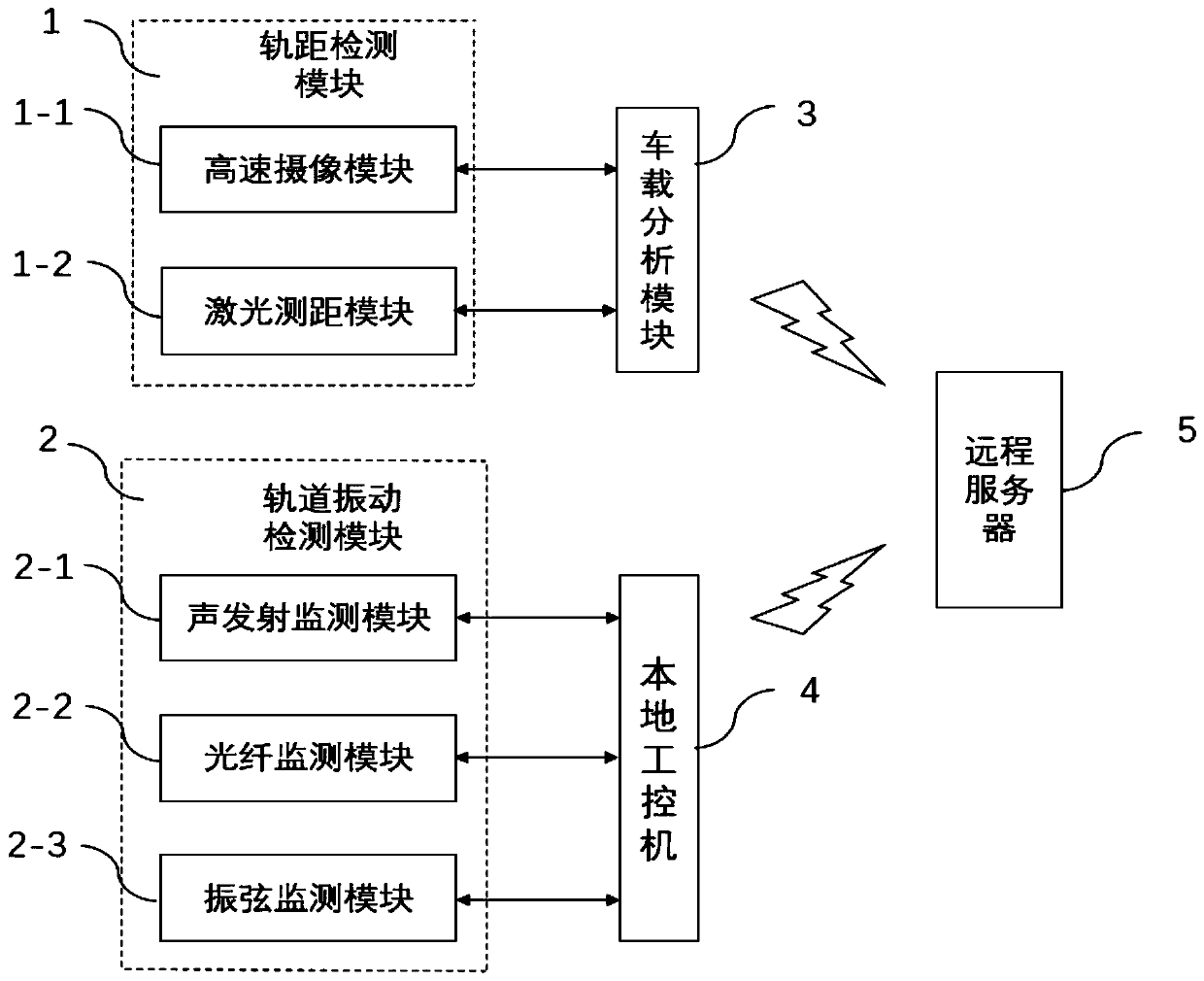

[0028] A high-speed railway track condition dynamic monitoring device, comprising a gauge detection module 1 and a vehicle-mounted analysis module 3 connected thereto, a track vibration detection module 2 and a local industrial computer 4 connected thereto, and a remote server 5; the remote server 5 They are respectively connected to the on-board analysis module 3 and the local industrial computer 4 for communication.

[0029]The gauge detection module 1 includes a high-speed camera module 1-1 and a laser distance measuring module 1-2; the high-speed camera module 1-1 and the laser distance measuring module 1-2 are all connected with the on-board analysis module 3, and the high-speed The camera module 1-1 is installed at the bottom of the train to take pictures of the train wheels and tracks; the laser distance measuring module 1-2 is installed on two opposite wheel hubs, and the distance between the two hubs is measured multiple times by means of opposite shots, and then the d...

Embodiment 2

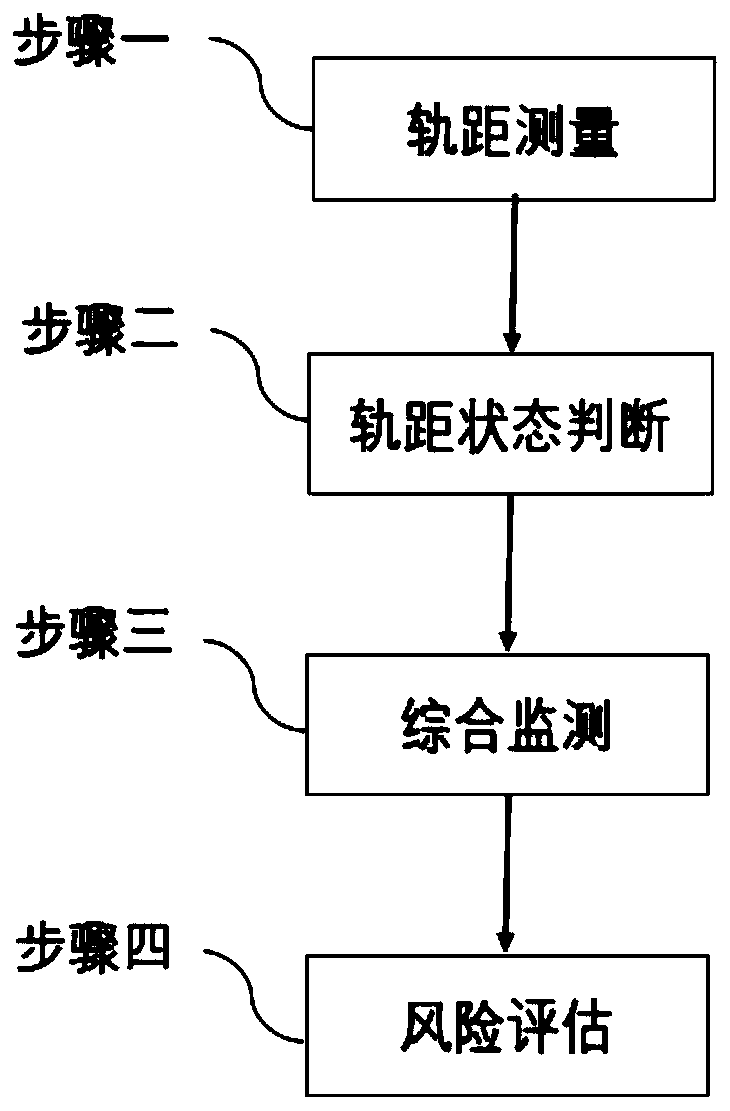

[0038] A method for dynamic monitoring of high-speed railway track conditions, using the above-mentioned device, and comprising the following steps:

[0039] Step 1. Gauge measurement: use the laser ranging module 1-2 installed on the two opposite wheel hubs to measure the distance between the two hubs multiple times to calculate the gauge, and start the high-speed camera module 1-1 when the gauge exceeds the preset threshold Take multiple images of train wheels and tracks;

[0040] Step 2. Judgment of gauge state: extract the image features of the rails and wheels from the multiple pictures of the train wheels and tracks taken, and then judge whether the rails are in an abnormal deformation state;

[0041] Step 3, comprehensive monitoring: record the corresponding position when it is judged that the rail is in an abnormally deformed state, and further monitor the rail. The further monitoring includes the monitoring of internal defects of the rail, track vibration and the foun...

Embodiment 3

[0044] In this embodiment, others are the same as Embodiment 2, and the difference is that the step of judging whether the rail is in an abnormally deformed state in said step 2 is specifically:

[0045] Extract the image features of the rails and wheels from the captured images, the image features include texture features, shape features and local feature points, use the BRJEF algorithm to select several pixel point pairs in the field around the feature points of the rails and wheels, and pass Compare the gray values of these point pairs with the gray values of the normal rails and wheels in the database, and then obtain a concatenated binary bit string to describe each feature point, and use the Hamming distance to calculate the gray values of the rails and wheels Whether the value exceeds the threshold to determine whether the rail is in an abnormal deformation state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com