A round bottle labeling machine

A technology for labeling machines and round bottles, which is applied in the direction of labeling machines, labeling, and labeling, and can solve problems such as label falling off and label warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

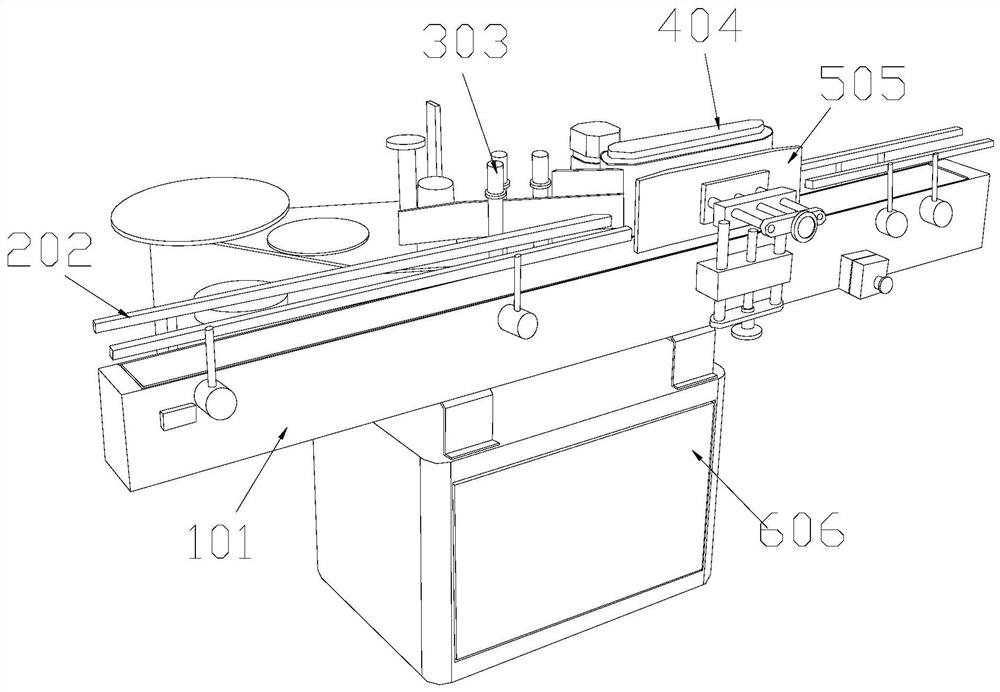

[0032] as attached figure 1 to attach Image 6 Shown:

[0033] The present invention provides a round bottle labeling machine, the structure of which includes a transport path 101, a side guard bar 202, a swivel body 303, a pressing body 404, a limit plate 505, and a bottom control box 606. The side guard bar 202 is welded to On the upper surface of the transport path 101, the swivel body 303 is installed on the side surface of the pressing body 404, the limiting plate 505 is placed on the upper surface of the transport path 101, and the end of the transport path 101 away from the side guard bar 202 is connected to the bottom control box 606 are connected.

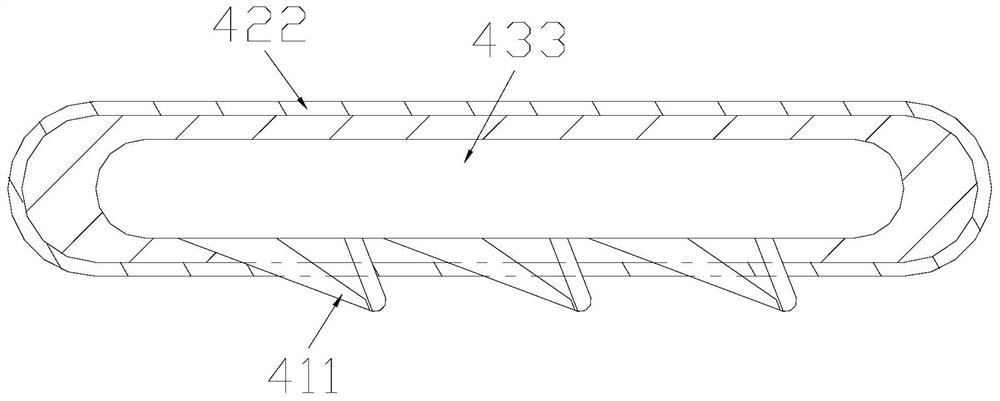

[0034] The pressing body 404 includes a conforming angle 411, an outer ring body 422, and an inner solid core 433. The inner solid core 433 is embedded in the middle end of the outer ring body 422, and the conforming angle 411 is fixed to the inner solid core. 433 exterior surfaces.

[0035] Wherein, the conforming cor...

Embodiment 2

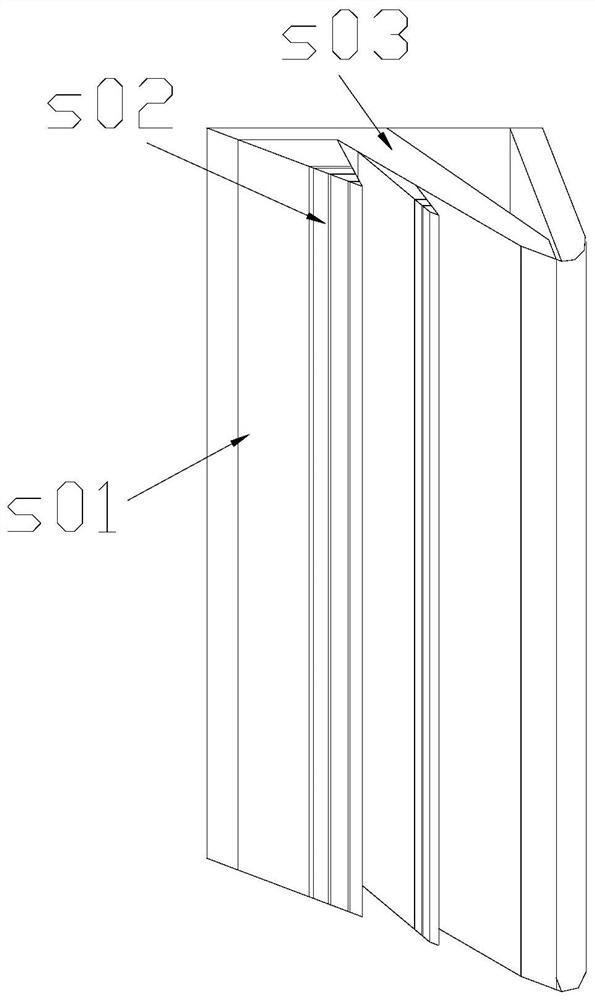

[0042] as attached Figure 7 to attach Figure 9 Shown:

[0043] Wherein, the forward pressure body e3 includes a solid m10 and a swing edge m20, the swing edge m20 is connected to the solid m10, the swing edge m20 is an arc structure, and the swing edge m20 guides the overall bending effect.

[0044]Wherein, the swing edge m20 includes an inclination angle k11, an arc k22, and a rubber strip k33, the inclination angle k11 is embedded inside the rubber strip k33, and the rubber strip k33 is connected with the arc k22, and the inclination angle k11 is Triangular structure, the rubber strip k33 is made of rubber material and has a certain degree of ductility, the inclination angle k11 guides the movement direction of the connecting parts, and the arc k22 fixes the overall bending angle and direction.

[0045] Wherein, the arc opening k22 includes an arc 61, an elastic ball 62, and a compartment opening 63, and the elastic ball 62 is connected with the arc 61, and the arc 61 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com