A shelf that can be replenished automatically and its working method

A shelf and automatic technology, applied in the field of automatic replenishment shelves, to achieve good anti-theft effect, convenient maintenance, and reduce the time for manual replenishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

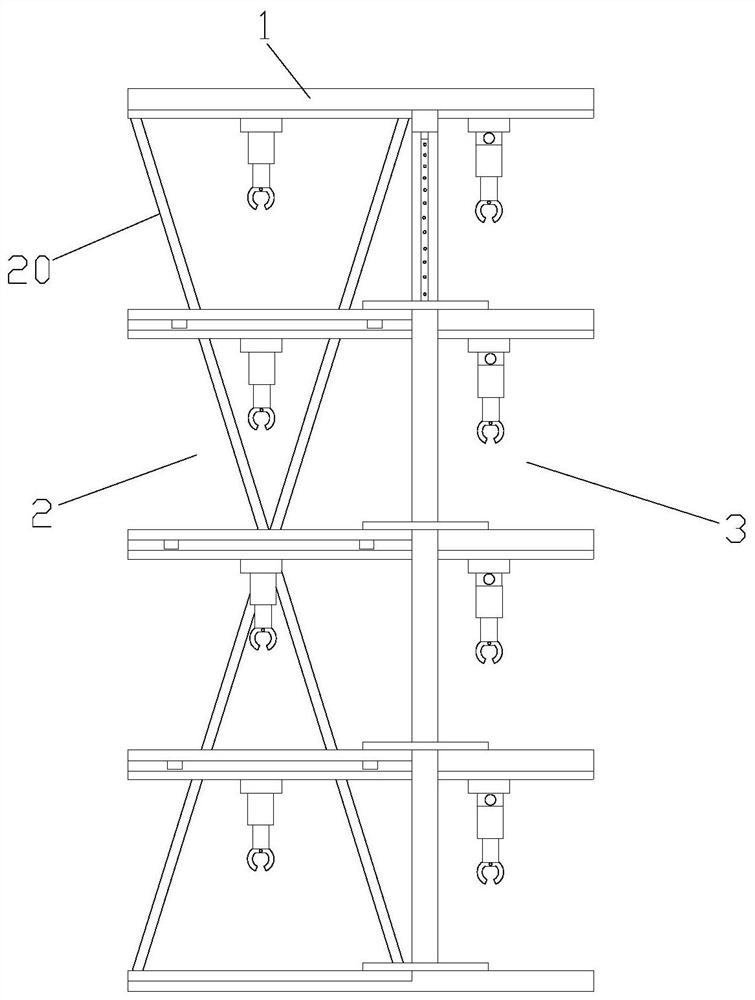

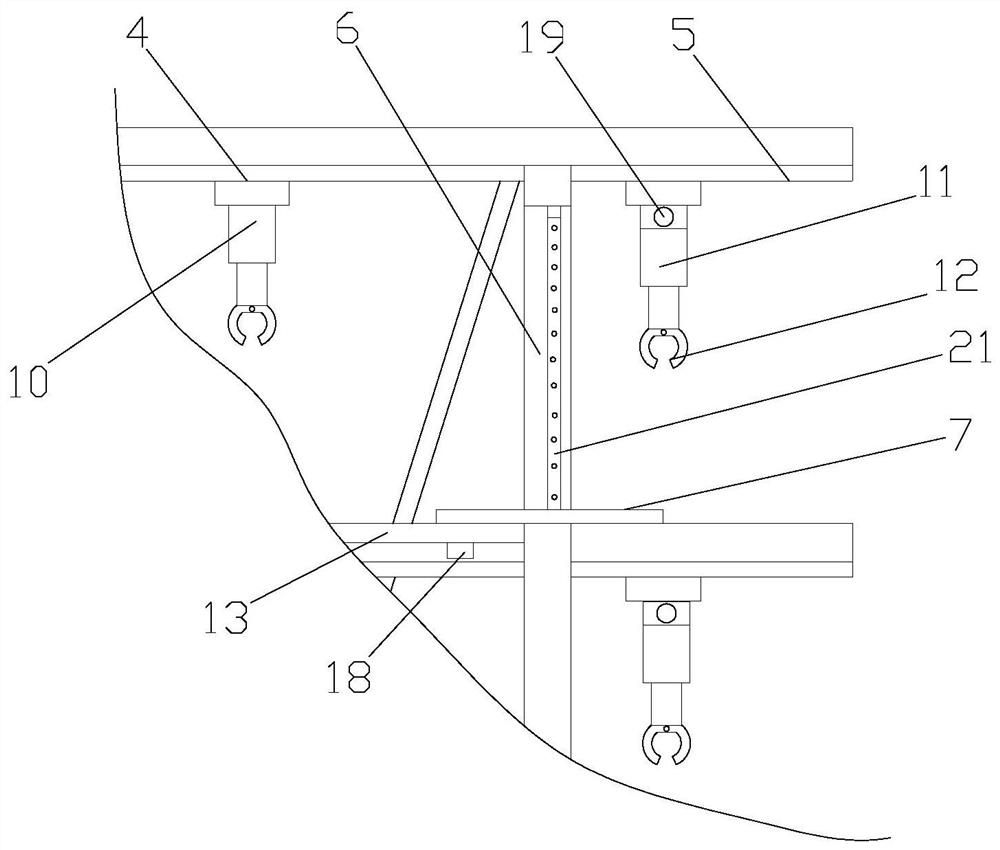

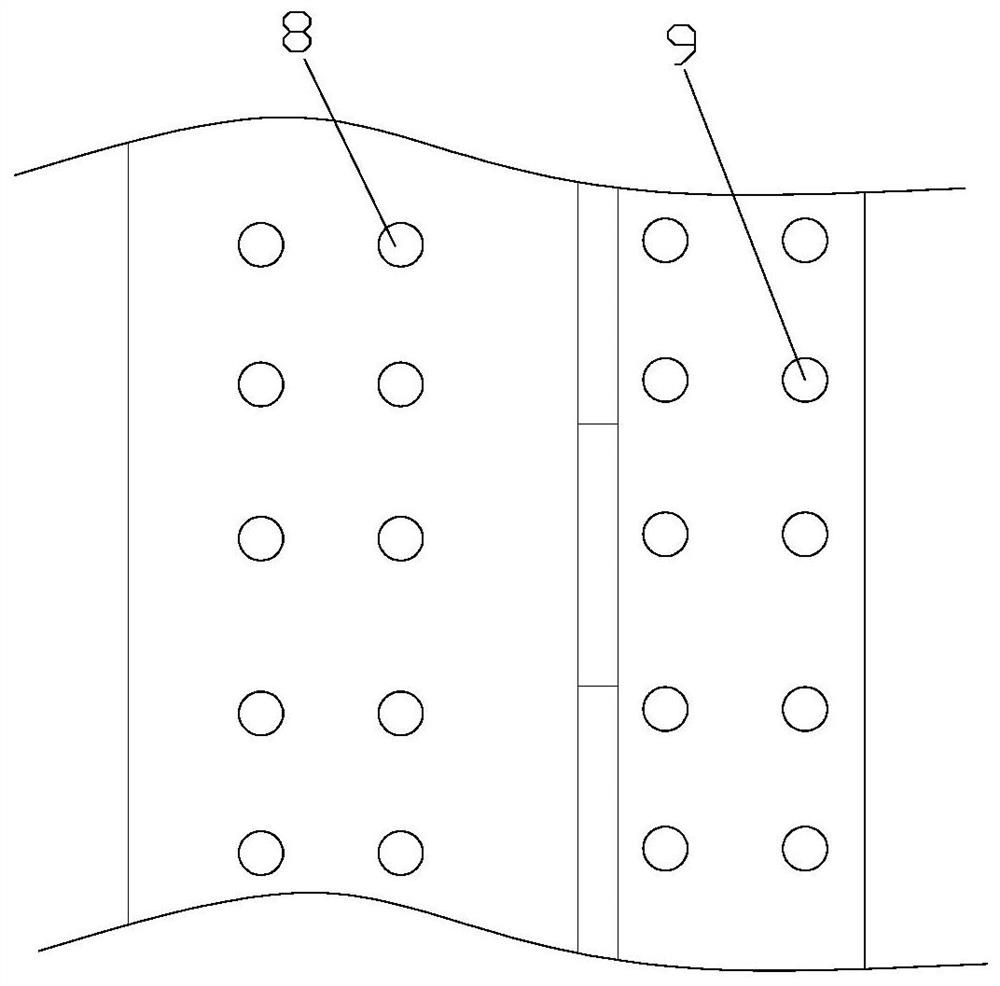

[0034] Such as Figure 1-4 As shown, a shelf capable of automatic replenishment includes a shelf body 1 and a control device (not shown), the shelf body 1 is formed with a replenishment area 2 and a sales area 3, and the replenishment area 2 and the sales area A first electric cross slide 4 and a second electric cross slide 5 are respectively arranged in the cargo area 3, and both the first electric cross slide 4 and the second electric cross slide 5 are fixedly connected with the frame body 1, and the A connection port 6 is provided on the frame body 1, and the replenishment area 2 and the sales area 3 are connected through the connection port 6, and a conveyor 7 is provided on the frame body 1, and the conveyor 7 passes through the connection port 6 And it is fixedly connected with the frame body 1, one end of the conveyor 7 is located in the replenishment area 2, the other end of the conveyor 7 is located in the sales area 3, and the replenishment area 2 and the sales area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com