Glass processing furnace

A glass and heating plate technology, used in glass furnace equipment, glass manufacturing equipment, furnaces, etc., can solve the problem that the flow hole cannot be closed and raised, and achieve the effect of increasing sealing and avoiding difficult opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

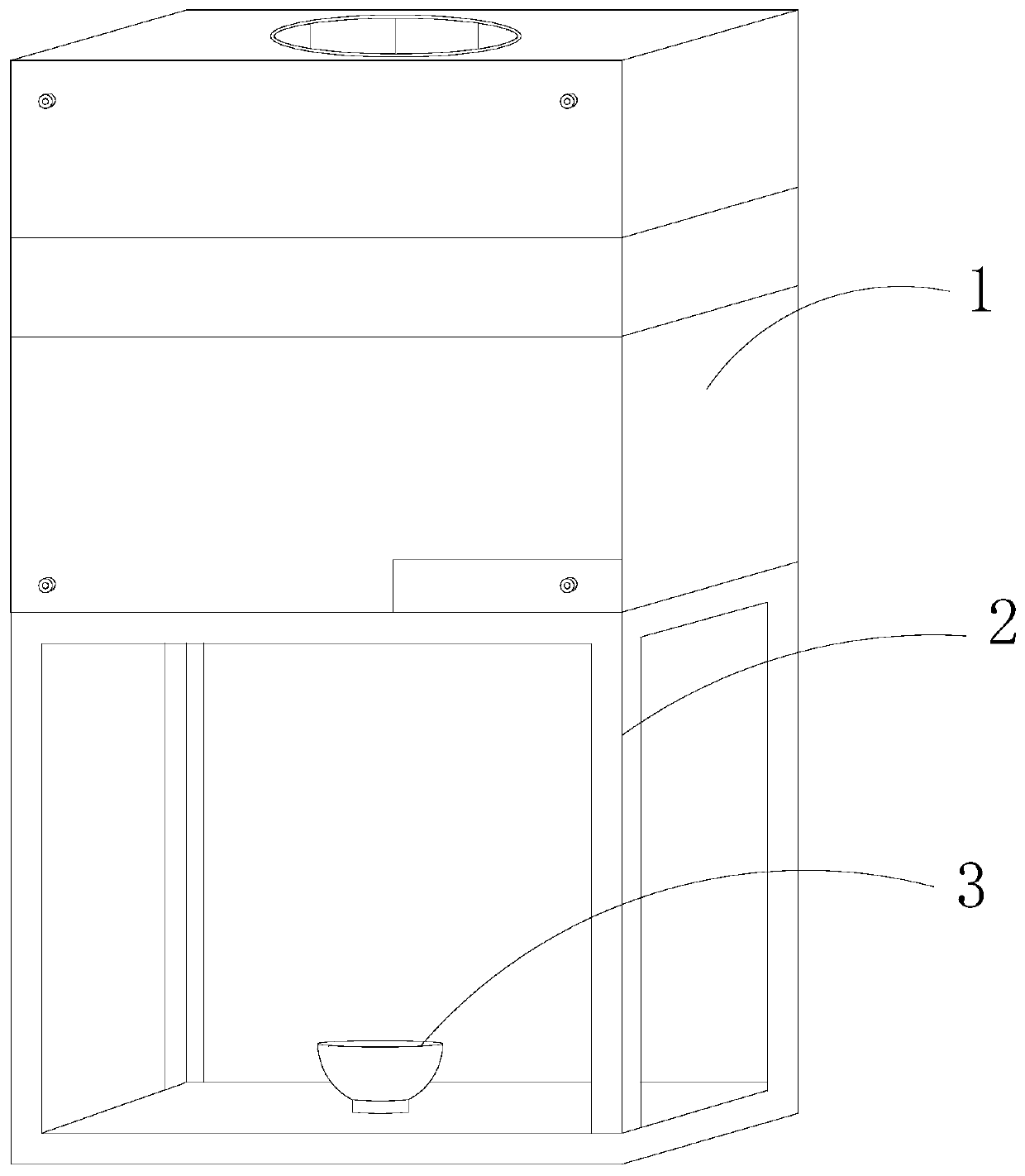

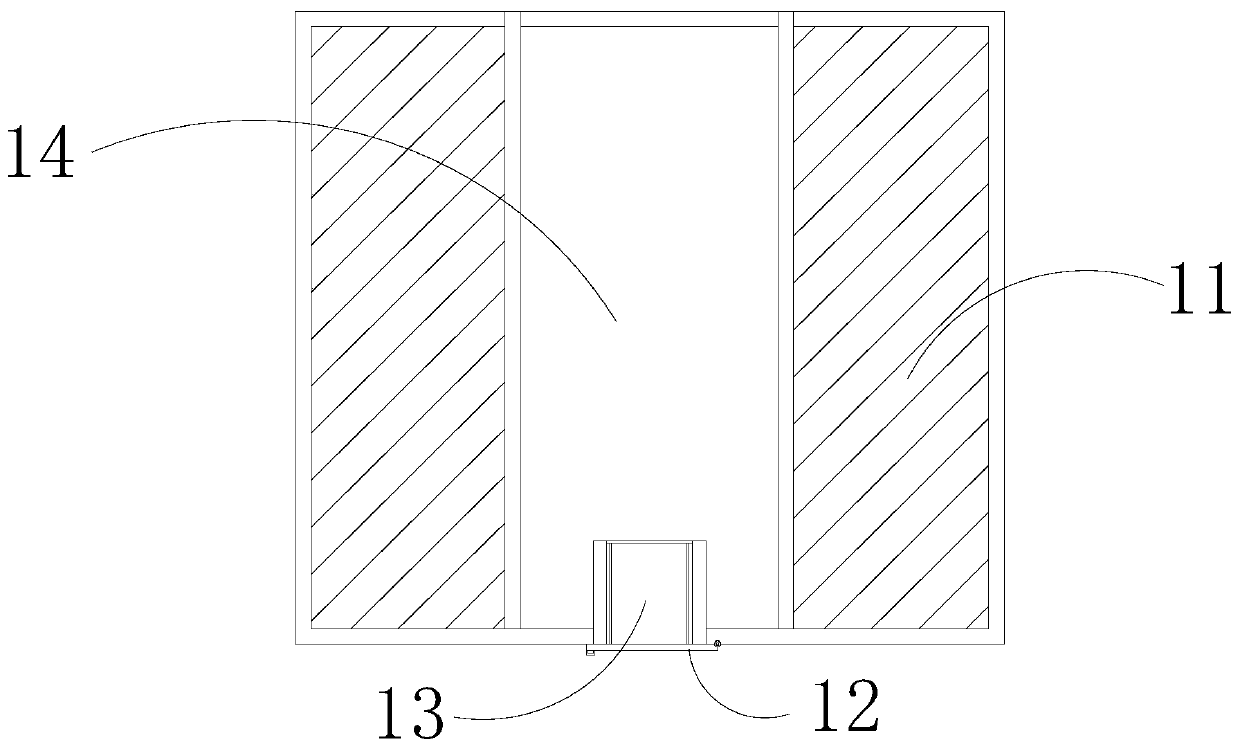

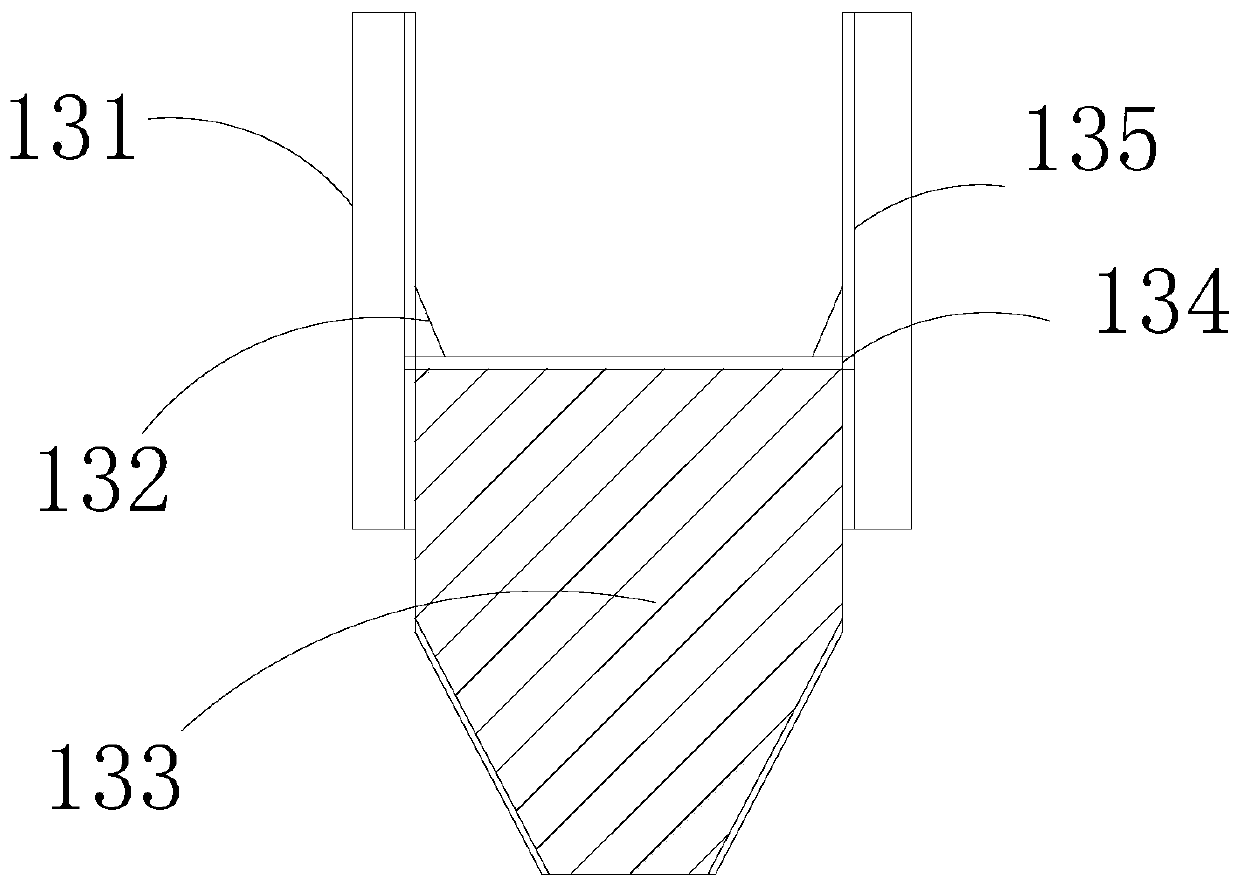

[0024] as attached figure 1 To attach Figure 5 Shown:

[0025] A glass processing furnace according to the present invention, its structure includes a fuselage 1, a support frame 2, and a container 3, the bottom of the fuselage 1 is welded to the top of the support frame 2, the bottom of the support frame 2 is provided with a container 3, and the container 3 is located under the fuselage 1, the fuselage 1 includes a heating plate 11, a door 12, a flow port 13, and a crucible 14, the heating plate 11 is arranged above the door 12, and the top of the door 12 is connected to the flow material The bottom of the mouth 13 conflicts, the flow mouth 13 is connected with the crucible 14, the outer wall of the crucible 14 is attached to the surface wall of the heating plate 11, and the material of the flow mouth 13 and the crucible 14 are the same, both of which are made of aluminum ingots , has the property of high temperature resistance, prevents the flow port 13 from being deforme...

Embodiment 2

[0032] as attached Figure 6 To attach Figure 8 Shown:

[0033]As a further improvement of the present invention, the outlet valve a2 includes a baffle a21, an outer fixed ring a22, and an inner fixed ring a23, the end of the baffle a21 is hingedly connected to the inner wall of the inner fixed ring a23, and the inner wall of the outer fixed ring a22 is connected to the inner wall of the inner fixed ring a23. The outer wall of the inner fixing ring a23 is fitted with a gap, the outer wall of the outer fixing ring a22 is welded to the inner wall of the main body a1, and there are eight baffles a21 in total, which are fixed around the inner fixing ring a23, and the inner fixing ring a23 is sealed to prevent the glass solution It flows out along the inner fixing ring a23 and adheres to the surface wall of the door 12 to avoid glass accumulation on the surface wall of the door 12.

[0034] As a further improvement of the present invention, the baffle a21 includes a baffle shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com