A method for making tipping paper for cigarettes with lasting positive sweetness

A technology for cigarette tipping paper and its production method, which is applied in the fields of special paper, printing of special varieties of printed matter, tobacco, etc., can solve the problem of sweetener attenuation, the reduction of surface content distribution, and the failure to solve effectively and systematically. Reduce the dryness of the mouth, increase the sense of body fluid, and increase the effect of delicious taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

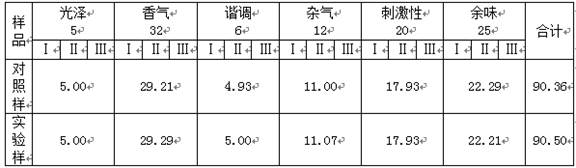

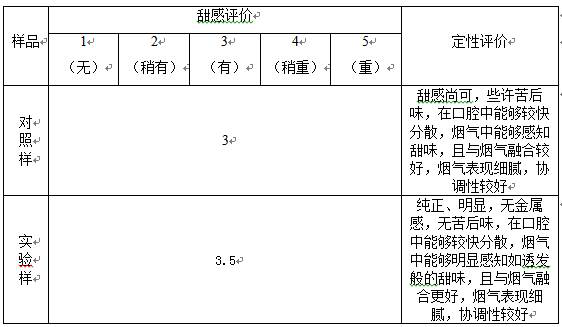

Examples

Embodiment 1

[0025] (1) The preparation of sweeteners: the weight ratios are respectively 55% ethyl acetate, 1% neotame, 4.5% alitame, 1% citric acid, 22% water, 5% sodium saccharin , 10% acesulfame potassium, and 1.5% triacetin were added to the container in a certain weight ratio, and stirred for 60 minutes by the disperser under the stirring condition of 600 r / min to make the mixture completely dissolved, stirred evenly, and prepared. Reserve as a sweetener.

[0026] (2) Preparation of sweet varnish: 55% ethanol, 10% water, 15% sweetener, and 20% ink are selected by weight, and the ink contains 7% digested cotton resin by weight. The liquid is added to the container according to a certain weight ratio, and stirred for 60 min under the stirring condition of 600 r / min by the disperser to completely dissolve the mixture, stir evenly, and prepare a sweet varnish for use.

[0027] (3) Take the base paper provided by a domestic tipping paper as the object, carry out three printings, one-colo...

Embodiment 2

[0030] (1) Preparation of sweeteners: 45% of ethyl acetate, 2% of neotame, 4% of alitame, 1% of citric acid, 29% of water, and 15% of acesulfame were selected by weight. Honey and 4% triacetin were added to the container in sequence according to a certain weight ratio, and stirred for 60 min under the stirring condition of 600 r / min through a disperser to completely dissolve the mixture, stir evenly, and prepare a sweetener for later use.

[0031] (2) Preparation of sweet varnish: 55% ethanol, 10% water, 15% sweetener, and 20% ink are selected by weight, and the ink contains 7% digested cotton resin by weight. The liquid is added to the container according to a certain weight ratio, and stirred for 60 min under the stirring condition of 600 r / min by the disperser to completely dissolve the mixture, stir evenly, and prepare a sweet varnish for use.

[0032] (3) The base paper provided by a domestic tipping paper is used as the object, and three times of printing are carried out...

Embodiment 3

[0035] (1) Preparation of sweeteners: 50% of ethyl acetate, 4% of neotame, 2% of alitame, 3% of citric acid, 24% of water, and 15% of acesulfame were selected by weight. Honey and 2% triacetin were added to the container in sequence according to a certain weight ratio, and stirred for 60 min under the stirring condition of 600 r / min through a disperser to completely dissolve the mixture, stir evenly, and prepare a sweetener for later use.

[0036] (2) Preparation of sweet varnish: 55% of ethanol, 10% of water, 15% of sweetener, and 20% of ink by weight are selected, and the ink contains 7% of digested cotton resin by weight. The liquid is added to the container according to a certain weight ratio, and stirred for 60 min under the stirring condition of 600 r / min by the disperser to completely dissolve the mixture, stir evenly, and prepare a sweet varnish for use.

[0037](3) Take the base paper provided by a domestic tipping paper as the object, carry out three printings, one-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com