Automatic reversing lock box

An automatic reversing and lock box technology, applied in non-mechanical transmission-operated locks, building locks, buildings, etc., can solve the problems of large motor workload, inconvenient use, and heavy component weight, and achieve the optimization of the internal structure of the lock, reducing The effect of motor load and convenient door opening and closing action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described in detail below, and examples of the embodiments are shown in the drawings, wherein the same or similar reference numerals denote the same or similar elements or elements having the same or similar functions throughout. The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention and should not be construed as limiting the present invention.

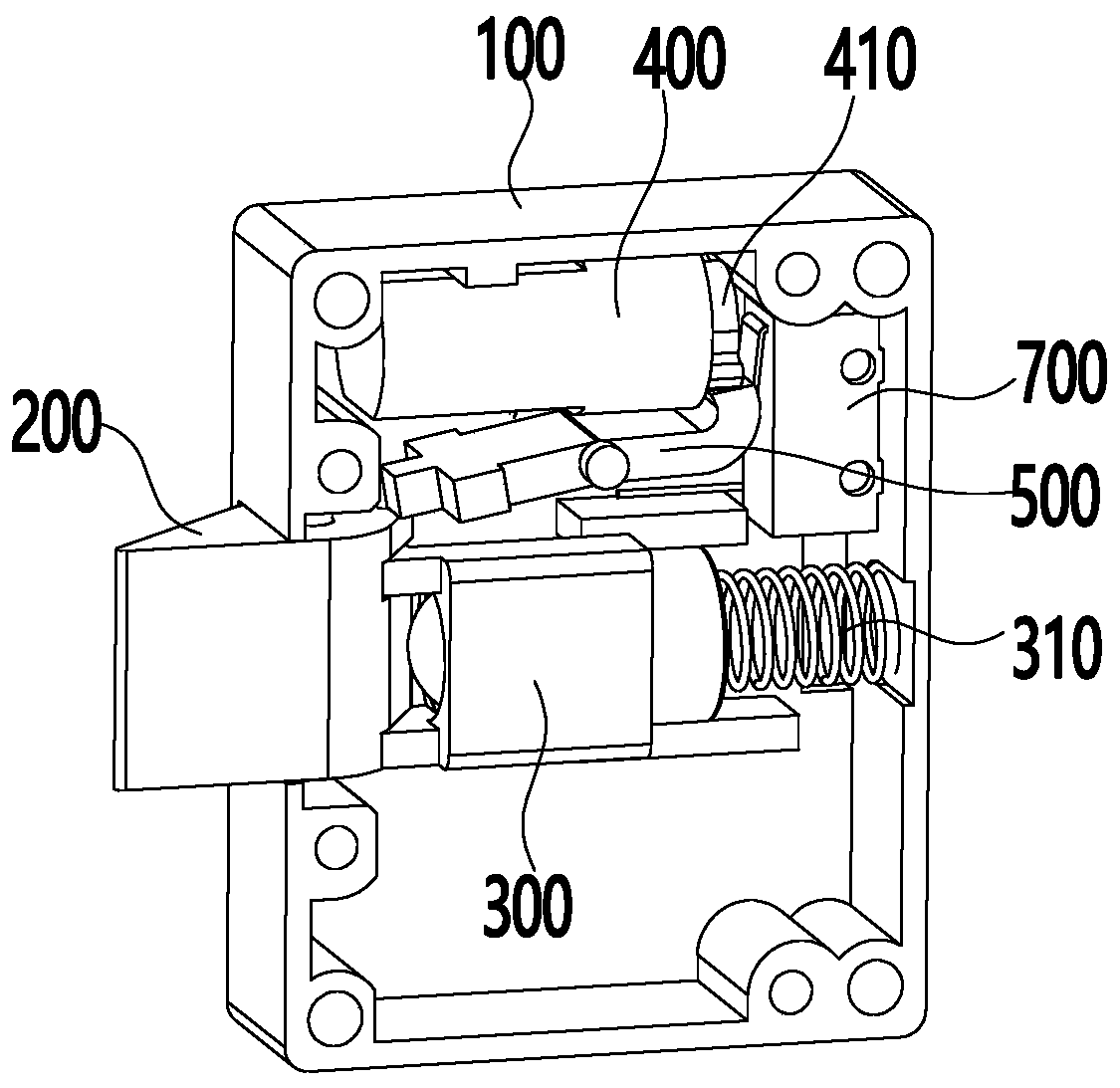

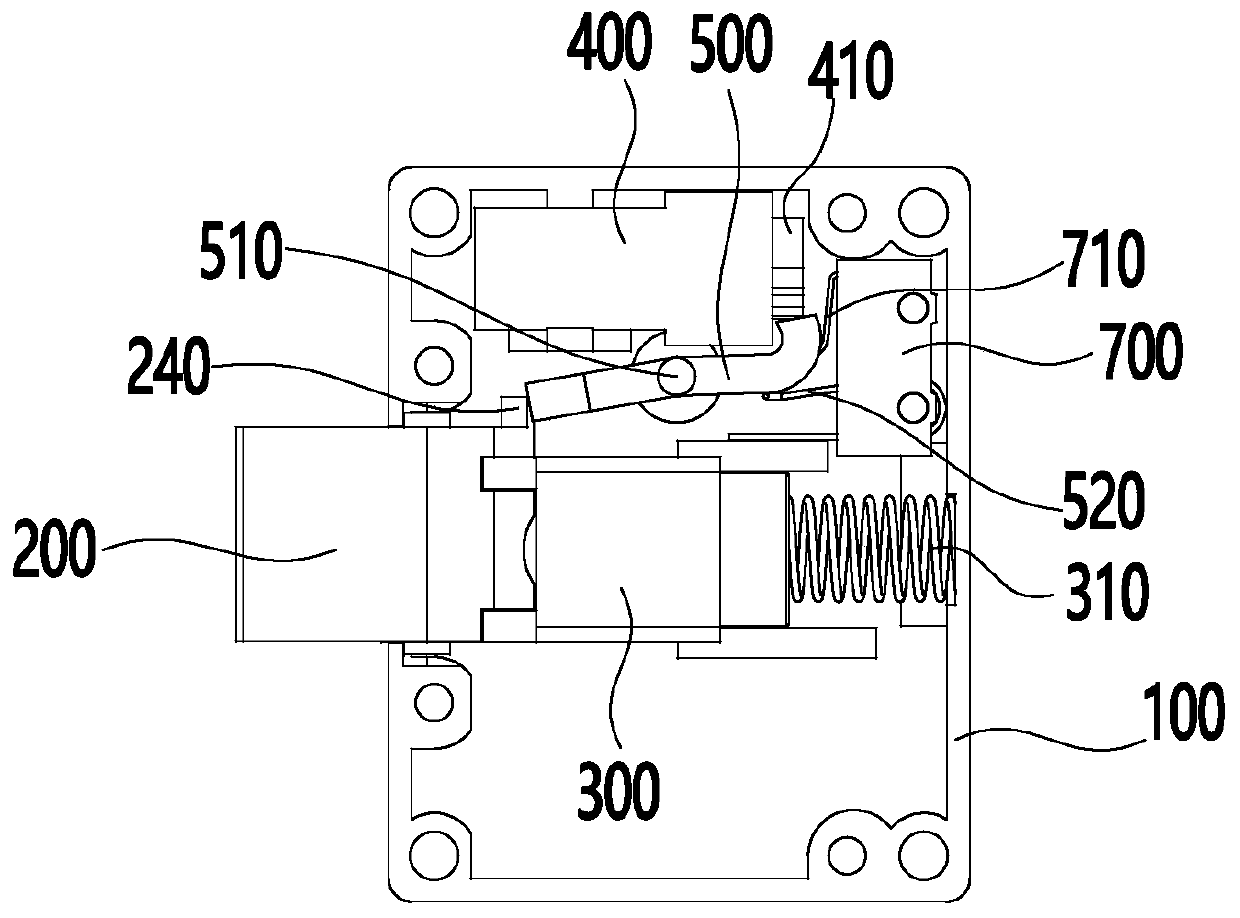

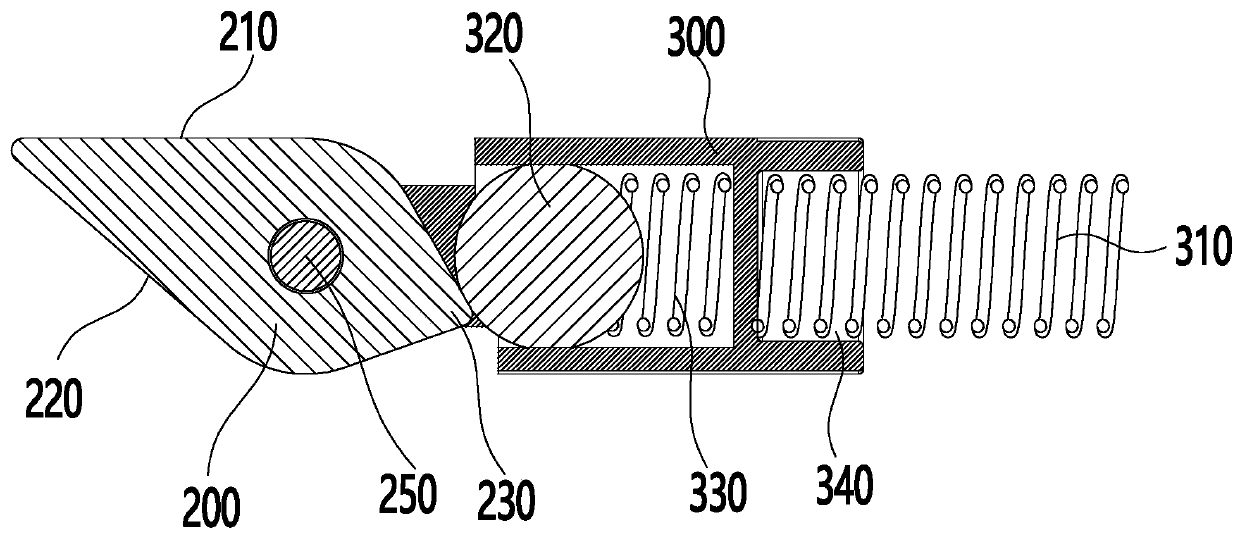

[0028] refer to figure 1 , figure 2 , image 3 and Figure 4 , an automatic reversing lock box, including a base 100, and also includes: a lock tongue mechanism, including a tongue body 200 and a connecting piece 300, the tongue body 200 is swingably connected to the connecting piece 300, and the tongue body 200 has symmetrically arranged first The inclined surface 210 and the second inclined surface 220, the connecting part 300 drives the tongue body 200 to telescopically move inside and outside t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap