Rectangular light spot lens module and preparation method thereof

A technology of lens module and rectangular light spot, applied in the field of rectangular light spot lens module and its preparation, can solve the problems of poor heat dissipation of products, high temperature of the lens module, affecting the accuracy of the lens, etc., so as to improve the air circulation efficiency and improve the heat dissipation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

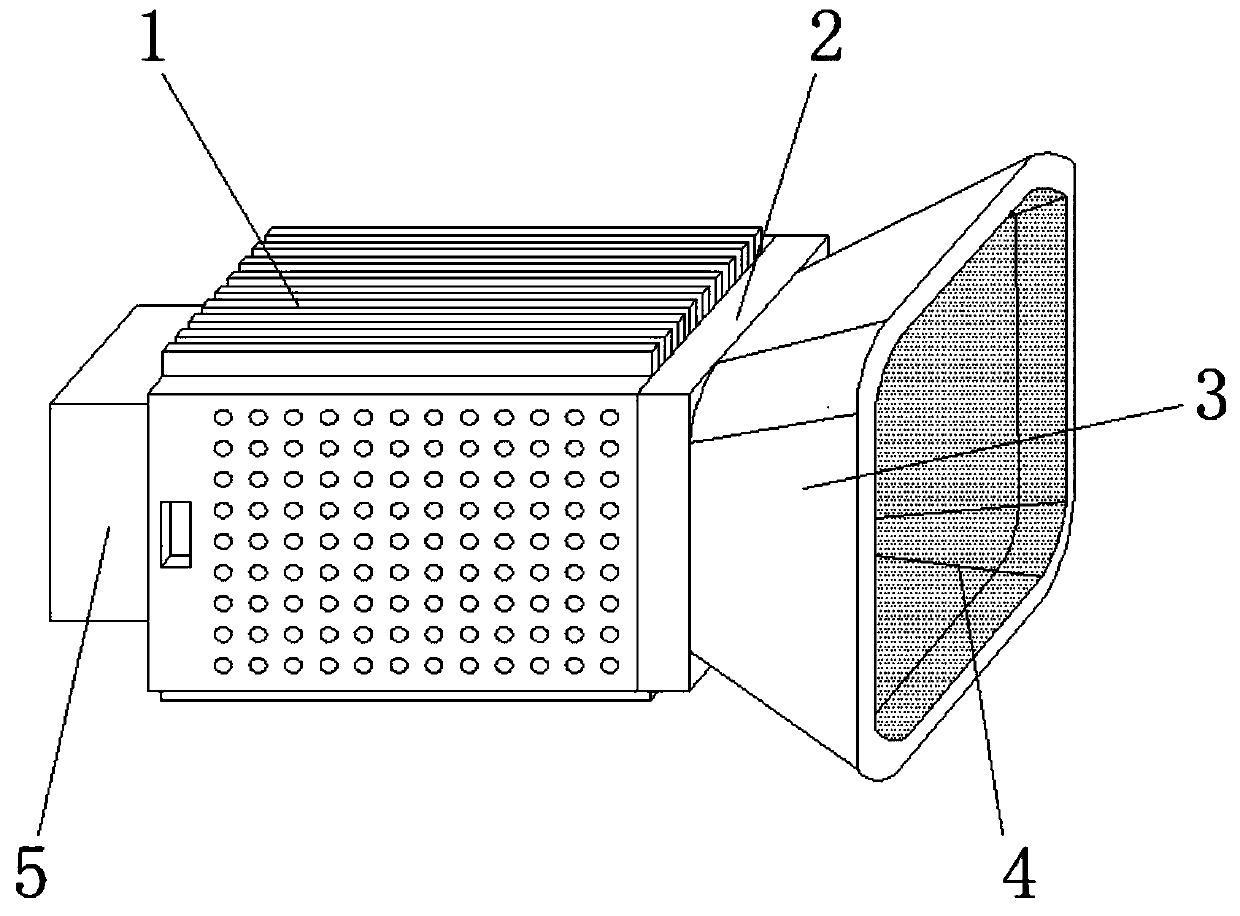

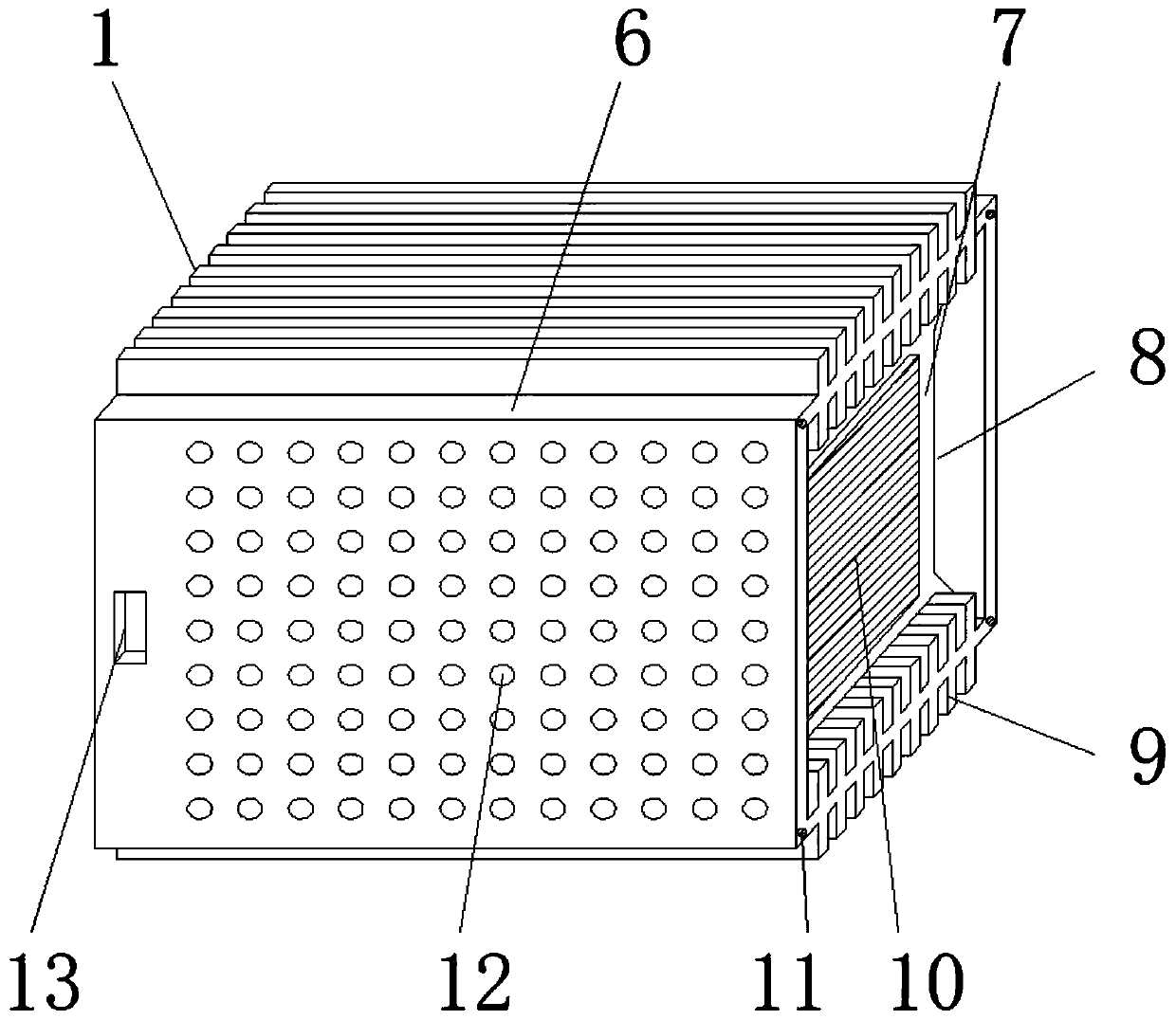

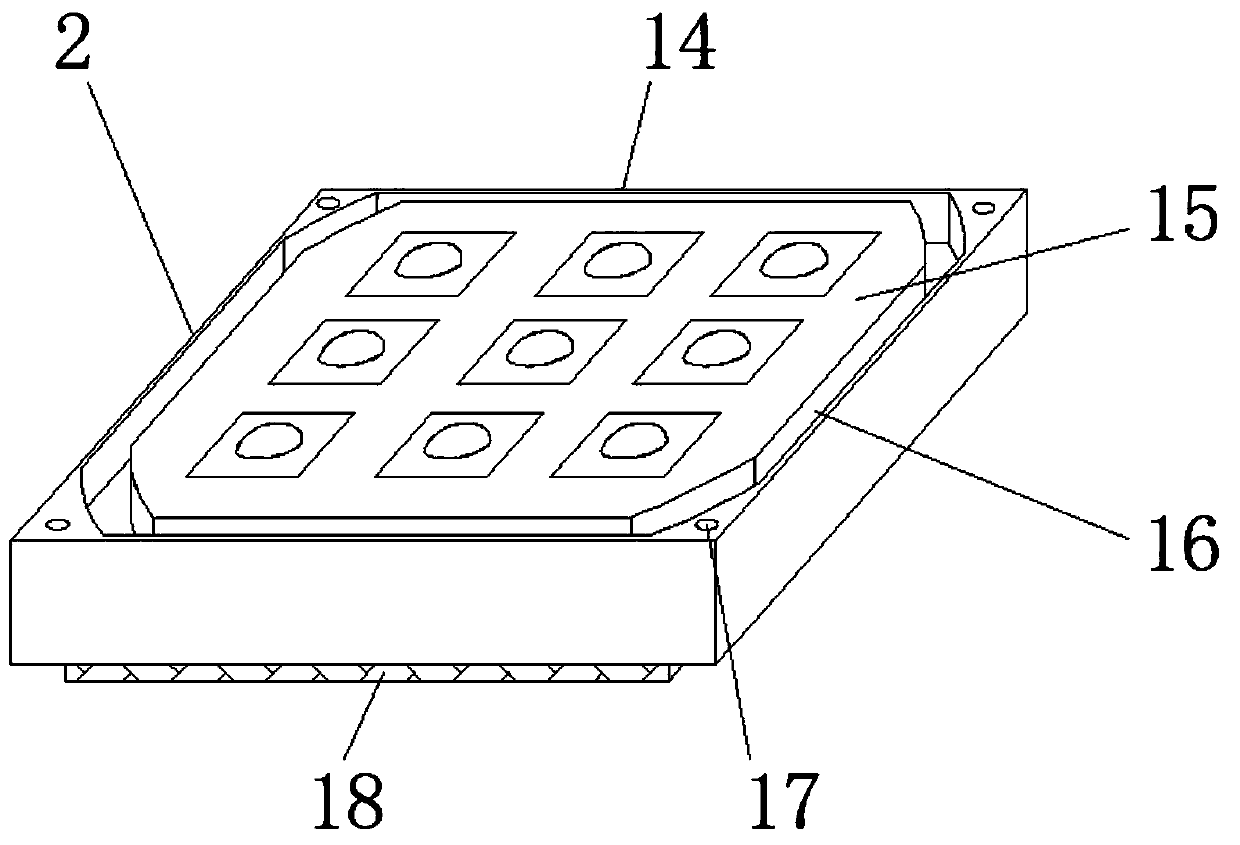

[0028] See Figure 1-Figure 4 As shown, one of the objectives of this embodiment is to provide a rectangular spot lens module including a heat dissipation module 1. The heat dissipation module 1 includes a heat dissipation module body 6, a heat dissipation member 7, an air gap 8, a heat dissipation fin 9, and a thermal conductive silicone grease 10. , Threaded holes 11, heat dissipation holes 12 and limit slots 13, the heat dissipation element 7 is fixedly clamped inside the heat dissipation module body 6, an air gap 8 is left between the heat dissipation module body 6 and the heat dissipation element 7, and the heat dissipation hole 12 is opened in the heat dissipation The front and rear surfaces of the module body 6 improve the air circulation efficiency inside the heat dissipation module body 6 and improve the heat dissipation effect of the device. The threaded holes 11 are opened in the four corners of the side end faces of the heat dissipation module body 6 away from the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com