Air fryer

An air fryer and cavity technology, which is applied to roaster/barbecue grids, kitchen utensils, household appliances, etc., can solve the problems of unreasonable air duct design, complex air fryer structure, poor assembly stability of components, etc. Simple and convenient disassembly and maintenance, improved cooking effect and quick processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

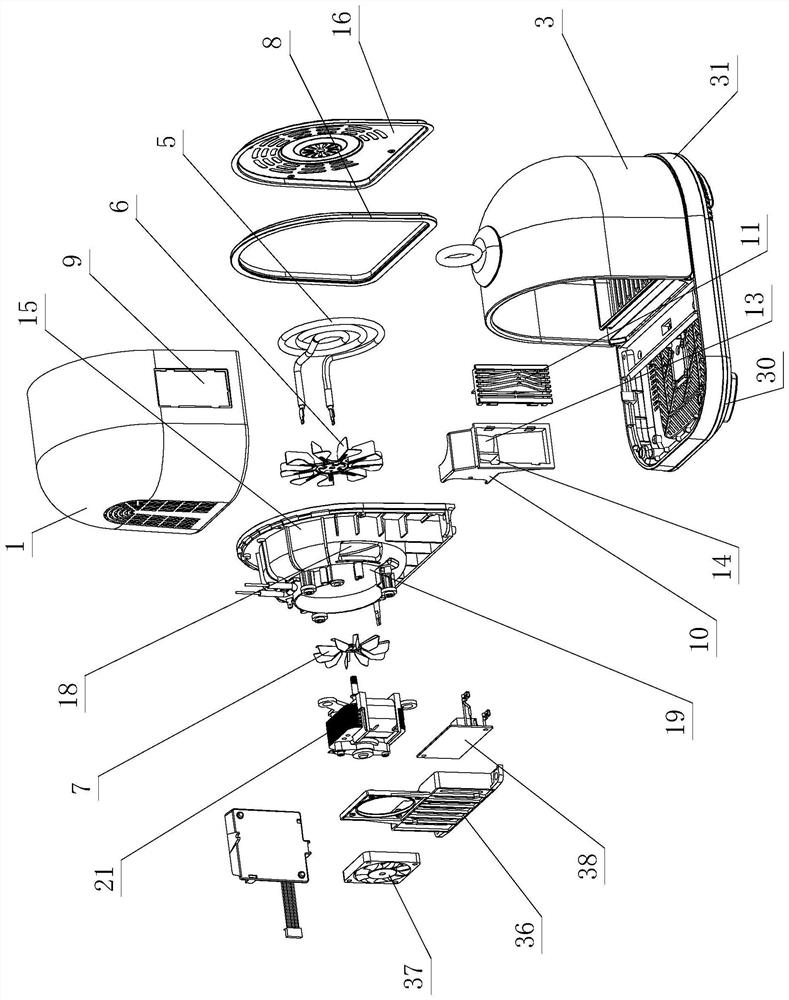

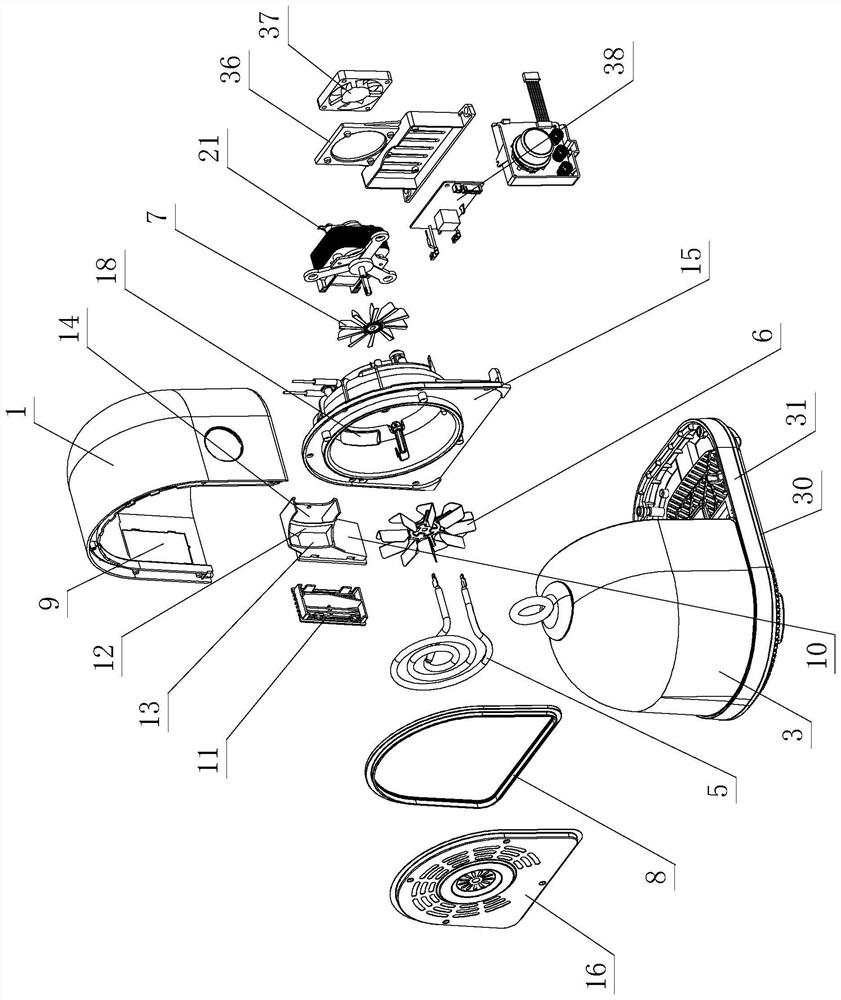

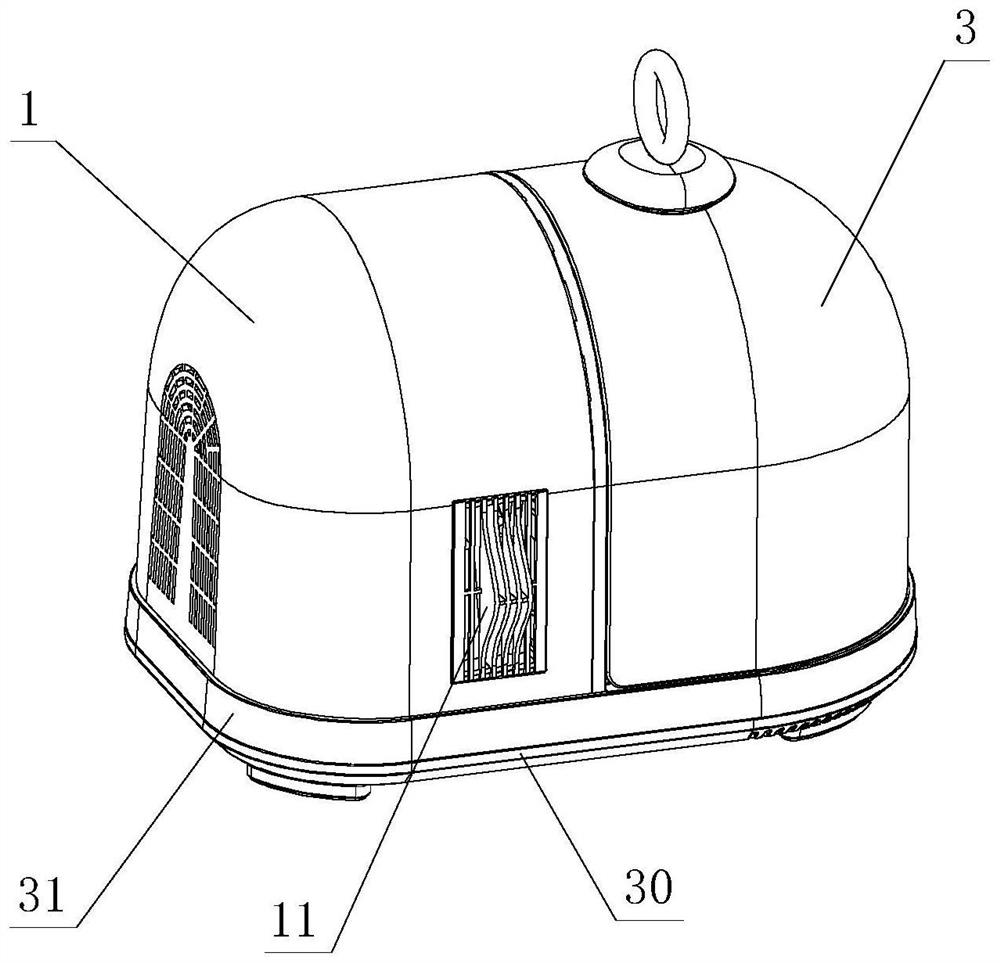

[0041] see Figure 1-Figure 17 , the air fryer includes a base assembly and a shell 1, the base assembly is provided with a windshield assembly; the shell 1 is located on one side of the windshield assembly, and is fixedly connected to the windshield assembly and / or the base assembly side, and mutually An assembly cavity 2 is formed between them; the other side of the windshield assembly is provided with a cover body 3, the cover body 3 is detachably arranged on the other side of the base assembly, and is horizontally opposed to the shell 1, and is assembled with the A cooking cavity 4 is formed between the base components; the assembly cavity 2 is provided with a heating element 5 that heats the air, blows the heat to the cooking cavity 4 in a circular manner, and heats the internal parts of the cooking cavity 4 to dissipate heat. Blade 6, and the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com