Novel boiler ignition gun and machining method thereof

A technology for ignition guns and boilers, which is applied in the directions of combustion and ignition, combustion methods, lighting and heating equipment, etc., can solve the problems of short circuit of water inlet, easy rupture and damage of insulating and fixed porcelain pipes, and difficulty in maintenance and disassembly, so as to improve safety performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described below with reference to specific examples. Those skilled in the art can understand that these examples are only used to illustrate the present invention and do not limit the scope of the present invention in any way.

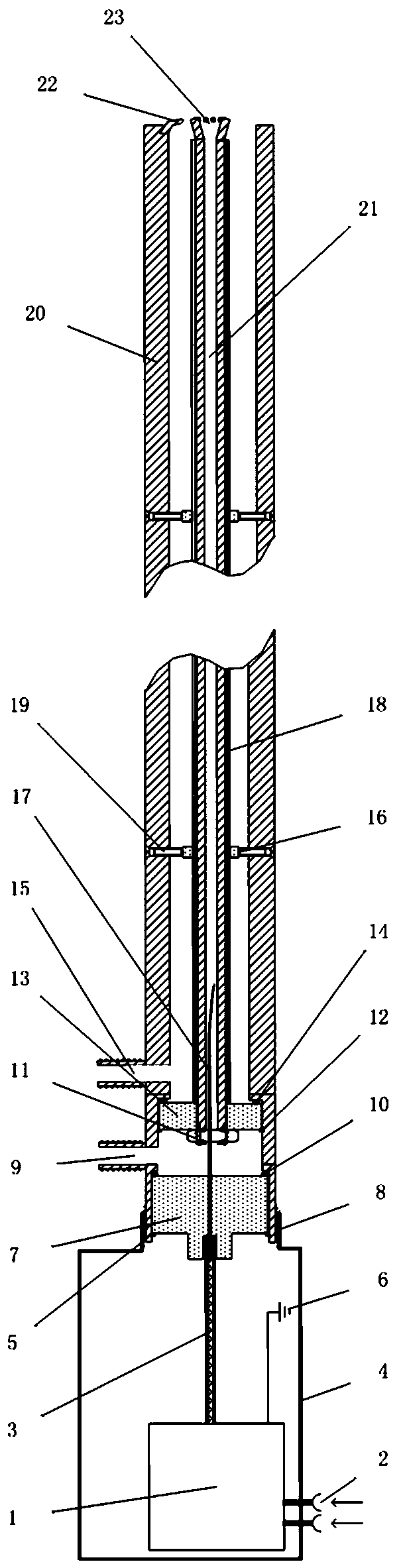

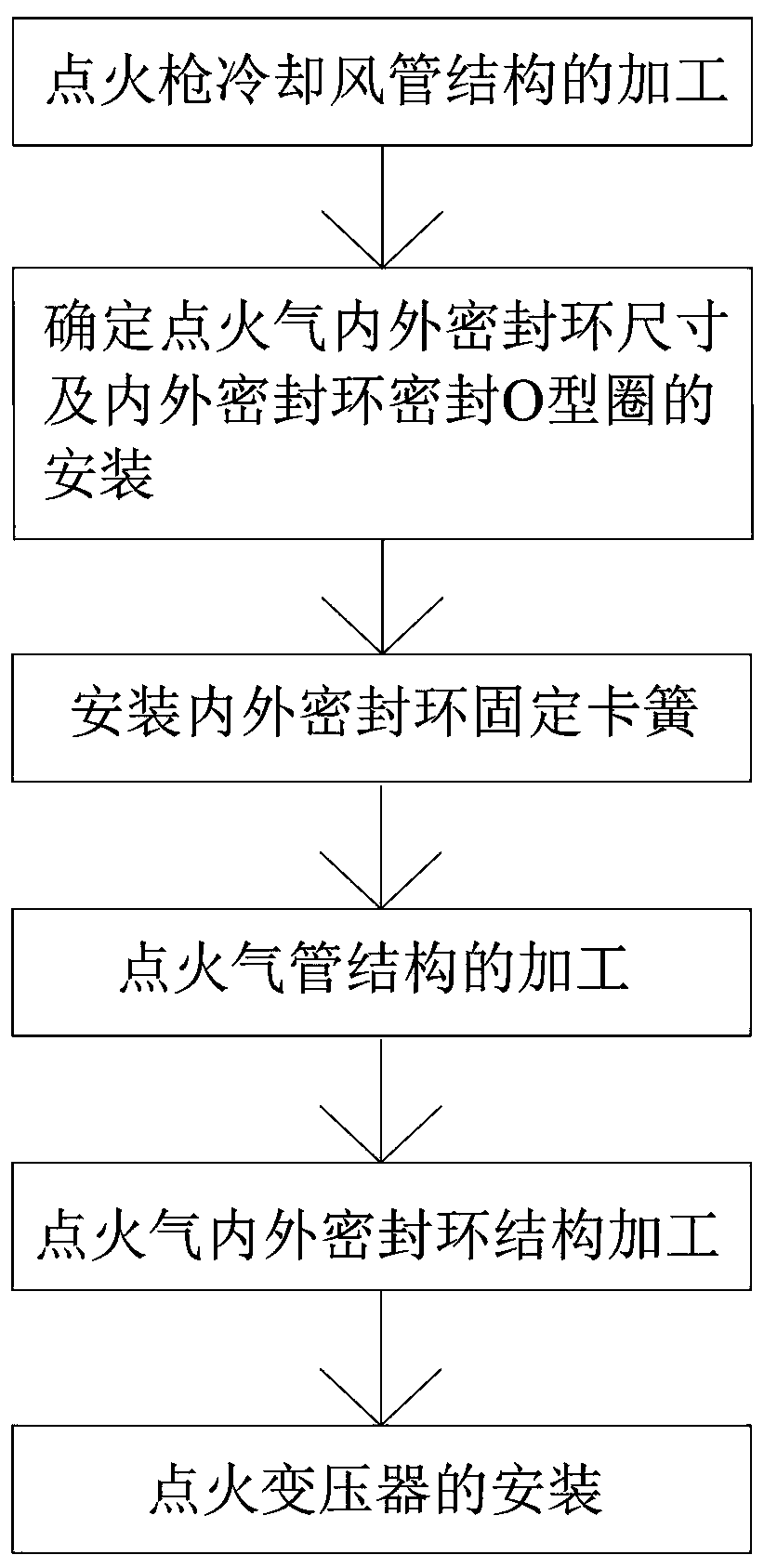

[0039] A new type of boiler ignition gun, such as figure 2 As shown, including ignition transformer part, ignition gas pipe part, combustion-supporting cooling air pipe part and combustion part;

[0040] The ignition transformer part is composed of the ignition transformer (1), the AC220V power aviation plug (2), the ignition transformer high-voltage arc output wire (3), the ignition transformer installation shell (4), the ignition transformer grounding wire (6), the ignition gas pipe and the ignition transformer installation Housing fixing thread (8), ignition transformer pantograph (17);

[0041] The ignition gas pipe part consists of the ignition gas pipe (21), the air inlet of the ignition gas pipe (9), the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com