Sand feeding method for diamond roller and diamond roller

A technology of diamond rollers and diamond powder, applied in metal processing equipment, grinding devices, grinding/polishing equipment, etc., can solve problems such as complex equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

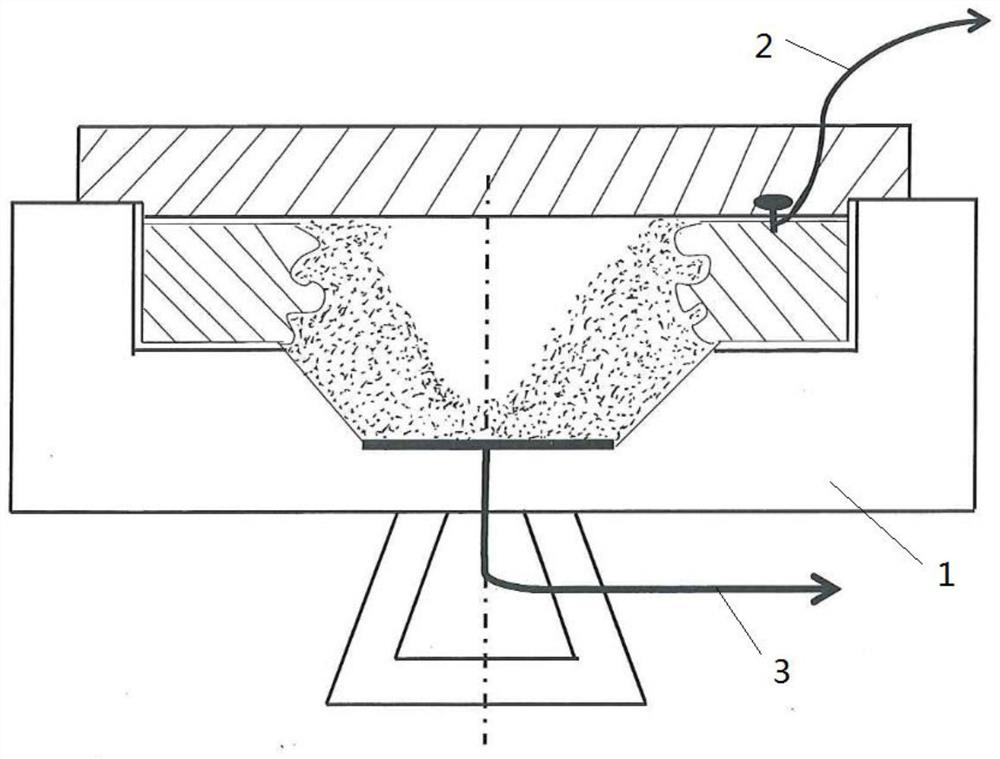

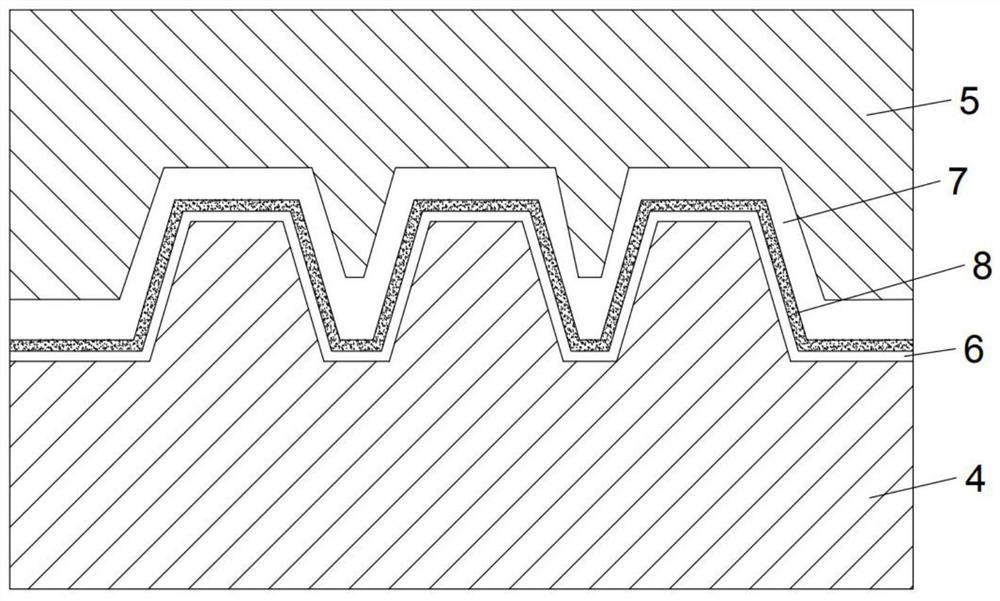

[0027] This embodiment provides a kind of sanding method of diamond roller, it comprises the following steps:

[0028] S1. After degreasing the negative mold used to make the diamond roller and washing it with warm water, apply the conductive adhesive on the surface of the negative mold to be sanded, with a coating thickness of 0.03-0.05mm, and obtain a glue-coated surface. female model.

[0029] S2. After cleaning the diamond (RJ.TJ) powder with hydrochloric acid, neutralize it with sodium hydroxide, and then place the diamond powder in a nickel-containing coating solution for soaking treatment, allowing it to deposit a trace amount of metal Ni Ionic components, and then washed with distilled water, and dried to obtain the processed diamond powder; the spray speed of the processed diamond powder is faster, which is very beneficial for sanding. Among them, the nickel-containing coating solution includes the following components: NiSO 4 ·7H 2 O 250g / L, CoSO 4 ·7H 2 O 20g / L...

Embodiment 2

[0035] This embodiment provides a kind of sanding method of diamond roller, it comprises the following steps:

[0036] S1. After degreasing the negative mold used to make the diamond roller and washing it with warm water, apply the conductive adhesive on the surface of the negative mold to be sanded, with a coating thickness of 0.03-0.05mm, and obtain a glue-coated surface. female model.

[0037] S2. After cleaning the diamond (RJ.TJ) powder with hydrochloric acid, neutralize it with sodium hydroxide, and then place the diamond powder in a nickel-containing coating solution for soaking treatment, allowing it to deposit a trace amount of metal Ni Ionic components, and then washed with distilled water, and dried to obtain the processed diamond powder; the spray speed of the processed diamond powder is faster, which is very beneficial for sanding. Among them, the nickel-containing coating solution includes the following components: NiSO 4 ·7H 2 O 200g / L, CoSO 4 ·7H 2 O 15g / L...

Embodiment 3

[0041] This embodiment provides a kind of sanding method of diamond roller, it comprises the following steps:

[0042] S1. After degreasing the negative mold used to make the diamond roller and washing it with warm water, apply the conductive adhesive on the surface of the negative mold to be sanded, with a coating thickness of 0.03-0.05mm, and obtain a glue-coated surface. female model.

[0043] S2. After cleaning the diamond (RJ.TJ) powder with hydrochloric acid, neutralize it with sodium hydroxide, and then place the diamond powder in a nickel-containing coating solution for soaking treatment, allowing it to deposit a trace amount of metal Ni Ionic components, and then washed with distilled water, and dried to obtain the processed diamond powder; the spray speed of the processed diamond powder is faster, which is very beneficial for sanding. Among them, the nickel-containing coating solution includes the following components: NiSO 4 ·7H 2 O 300g / L, CoSO 4 ·7H 2 O 25g / L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com