Suspension type magnetic flux leakage detection module

A magnetic flux leakage detection and suspension technology, applied in the direction of material magnetic variables, etc., can solve the problem of reducing the detection accuracy of the detection box, and achieve the effects of reducing the detection energy consumption, improving the detection accuracy and improving the fit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiment:

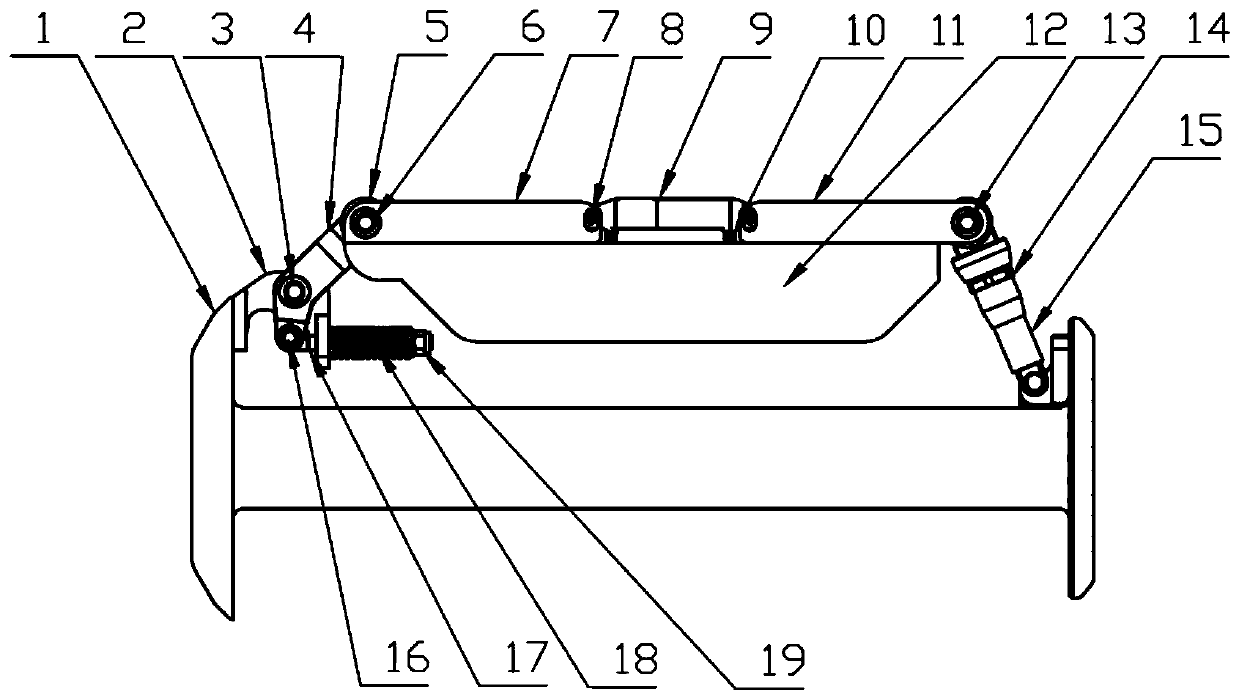

[0026] A suspended magnetic flux leakage detection module, comprising:

[0027] The magnetic flux leakage detection mechanism is used to detect the defects of the pipe wall;

[0028] The suspension connection mechanism, the magnetic flux leakage detection mechanism is connected with the detector bracket 1 through the suspension connection mechanism, and the suspension connection mechanism is used to enable the magnetic flux leakage detection mechanism to float inside and outside with the change of pipe diameter.

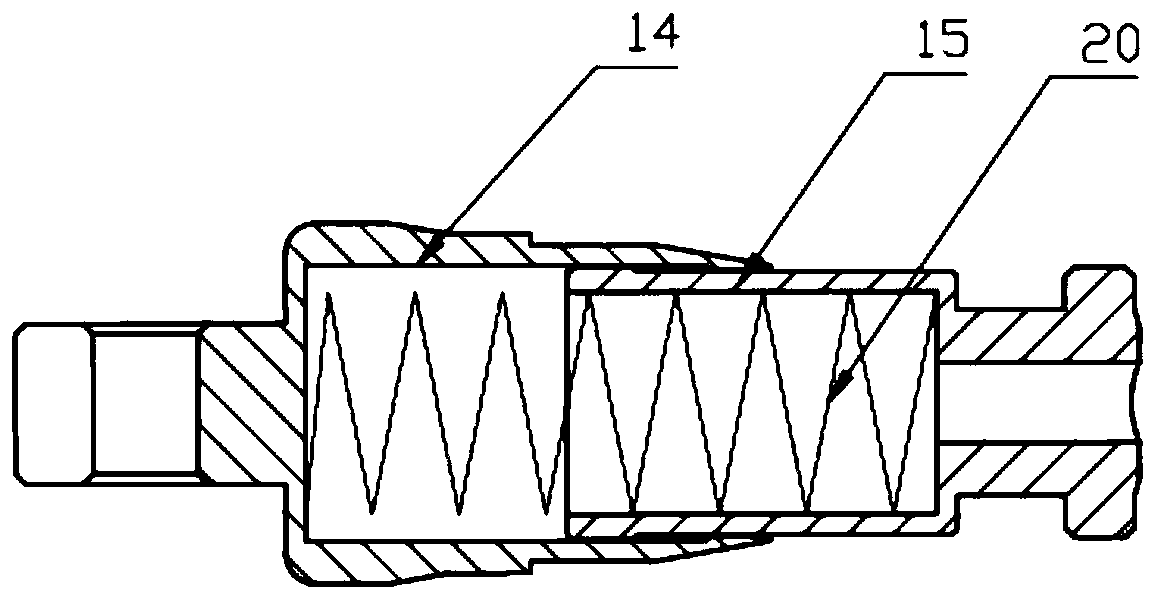

[0029] Further, the magnetic flux leakage detection mechanism includes a magnetic conduction module 12, the outer two ends of the magnetic conduction module 12 are respectively fixed with a front magnet module 7 and a rear magnet module 11, between the front magnet module 7 and the rear magnet module 11 A detection box 9 is provided.

[0030] Further, the detection box 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com