Battery module

A battery module and cell technology, applied in battery pack components, secondary batteries, circuits, etc., can solve the problems of unstable battery pack safety performance, and achieve the effect of improving battery safety and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

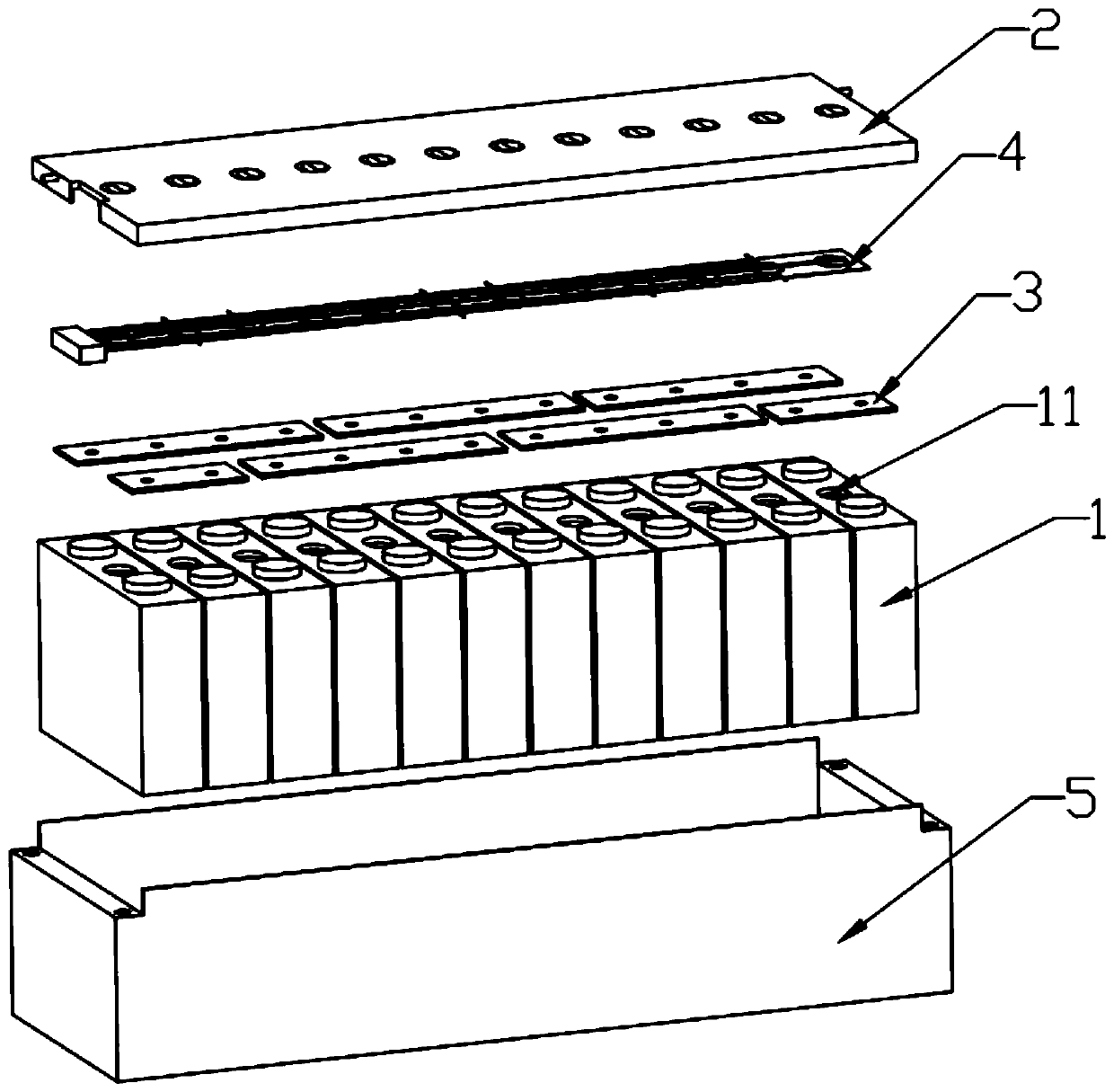

[0029] refer to figure 1 and figure 2 , the battery module involved in this application includes a battery cell 1 , a conductive medium 3 and a fire extinguishing device 2 . The cells 1 are rectangular parallelepiped cells or cylindrical cells, and each cell 1 is provided with an exhaust valve 11 on the top, and the cells 1 are arranged in sequence. The conductive medium 3 is arranged on the top of the cell 1 to electrically connect the cell 1 . Optionally, the conductive medium 3 is electrically connected to the cell 1 in series or in parallel. The fire extinguishing device 2 is set corresponding to the exhaust valve 11, refer to figure 1 , The fire extinguishing device 2 is arranged above the battery cell 1, and when thermal runaway occurs, the fire extinguishing treatment is performed on the battery cell 1.

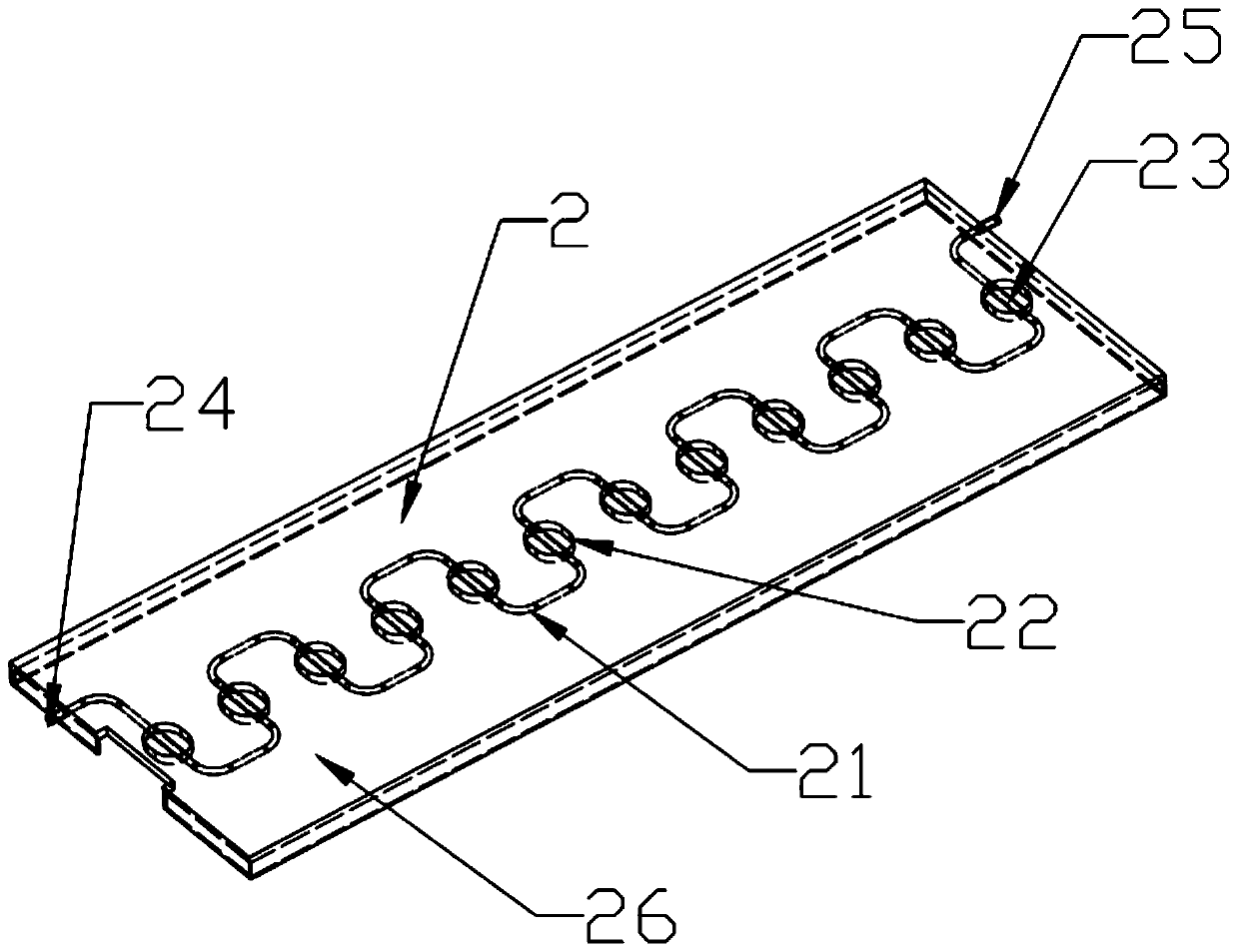

[0030] Depend on figure 2 As shown, the fire extinguishing device 2 includes a flow channel 21 , a first heat conduction hole 22 , a liquid discharge device 23 ,...

Embodiment 2

[0042] The second embodiment is a further improvement made on the basis of the first embodiment, and the specific difference between the second embodiment and the first embodiment is the structure of the liquid discharge device 23 .

[0043] refer to Figure 6 and Figure 7 , the liquid discharge device 23 includes a tubular body 231 and a liquid storage cavity 232 disposed in the middle section of the tubular body 231 . In the direction perpendicular to the flow of the coolant, the sectional area of the liquid storage cavity 232 is larger than that of the tubular body 231 . This setting can store more cooling fluid on the one hand, to ensure that when the liquid discharge device 23 is fused by the gas discharged from the exhaust valve 11, there will be a sufficient amount of cooling fluid to spray the thermally runaway battery cell; on the other hand, it can The contact area between the liquid discharge device 23 and the gas discharged from the exhaust valve 11 is increas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com