Riveting tool

A riveting tooling and riveting technology, applied in the field of riveting tooling, can solve the problems of high labor costs, increased parts costs, and low production efficiency, and achieve the effects of reducing product costs, saving energy consumption, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

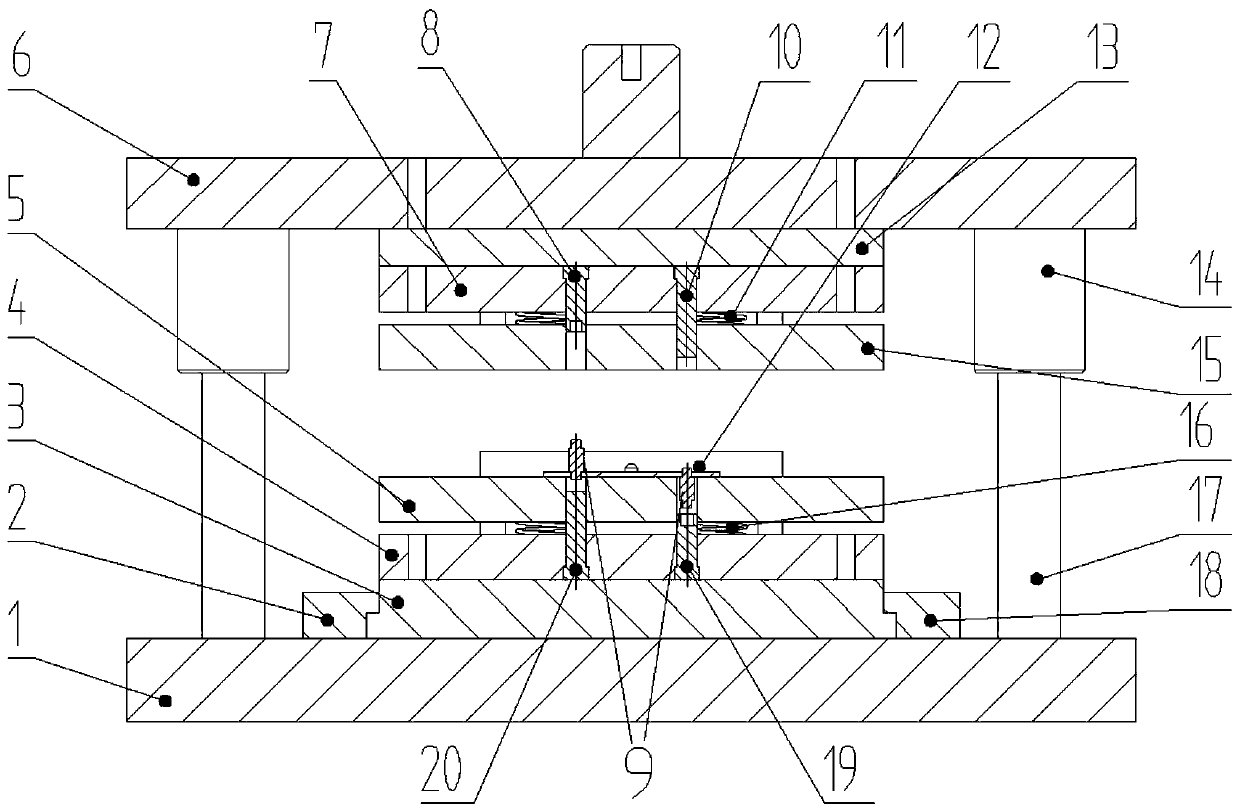

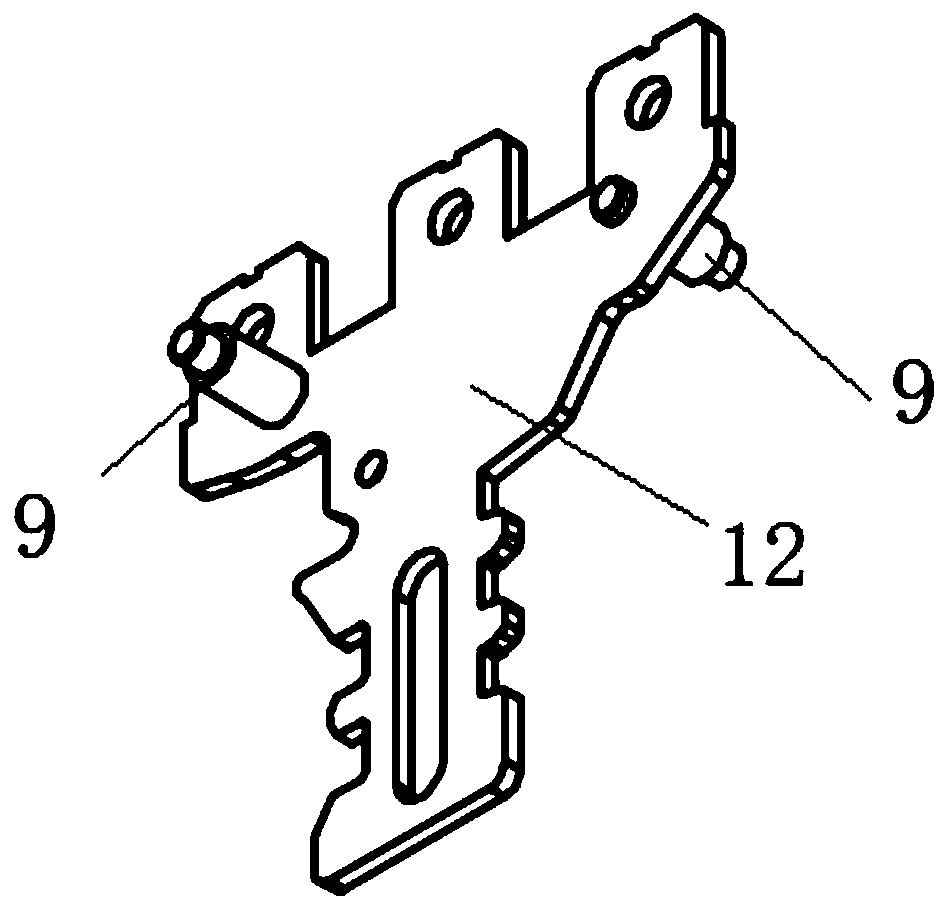

[0027] Such as figure 2 As shown, a riveting tool includes an upper template 6 and a lower template 1, including: an upper punch assembly, and the upper punch assembly includes a first upper punch 8 and a second upper punch installed on the upper template 6. Punch 10; upper stripping plate 15, two first through holes are provided on the upper stripping plate 15, and the first upper punch 8 and the second upper punch 10 are respectively arranged on the two first through holes. In the hole; the upper spring 11 is used to connect the upper stripping plate 15 to the upper template 6; the first upper punch 8 and the second upper punch 10 are all in the upper In the first through hole of the stripper plate 15.

[0028] The lower punch assembly, the lower punch assembly includes a first lower punch 19 and a second lower punch 20 installed on the lower template 1; the first lower punch 19 and the first upper punch 8 Cooperate, the second lower punch 20 and the second upper punch 10...

Embodiment 2

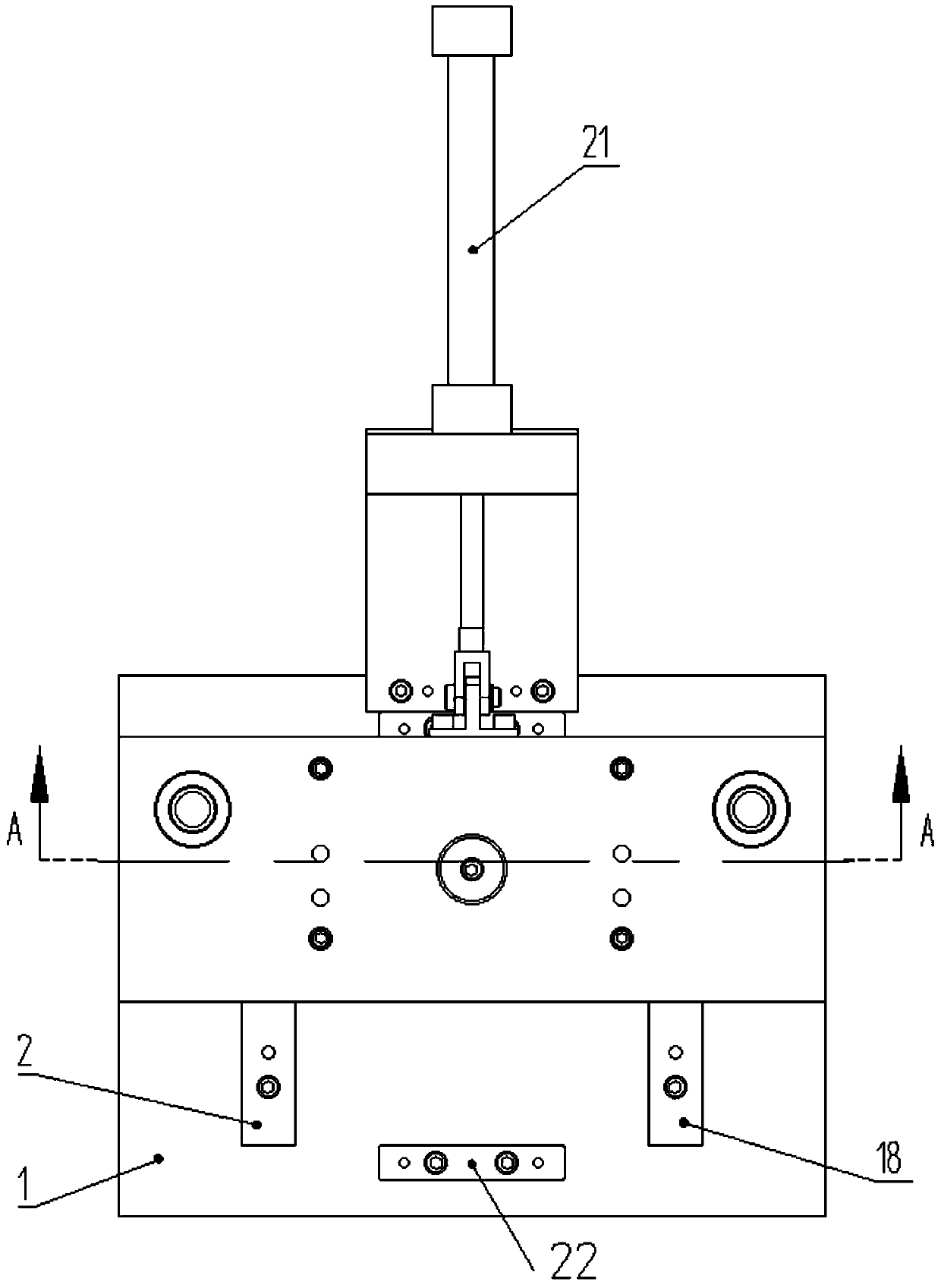

[0037] Such as figure 1 As shown, this implementation is further optimized on the basis of Embodiment 1. This embodiment focuses on the improvements compared with Embodiment 1, and the similarities will not be repeated. In this embodiment, the riveting tooling is also Including: a power assembly, the power assembly includes:

[0038] The lower die backing plate 3, the lower die backing plate 3 is slidably connected on the lower template 1, the lower punch assembly is fixed on the lower die backing plate 3, and the lower stripping plate 5 passes through the lower spring 16 is connected to the lower mold backing plate 3; power unit 21, the power unit 21 is connected to the lower mold backing plate 3; used to drive the lower mold backing plate 3 to reciprocate on the lower template 1 sports.

[0039] The power assembly is added, so that the lower mold backing plate 3 can be pushed out through the power device 21, so that the lower mold backing plate 3 moves together with the lo...

Embodiment 3

[0045] Such as figure 2 As shown, this implementation is further optimized on the basis of Embodiment 2. This embodiment focuses on the improvements compared with Embodiment 2, and the similarities will not be repeated. In this embodiment, the upper template 6 Upper die backing plate 13 is connected, and upper die backing plate 13 is connected with upper die punch fixing plate 7, and upper die punch fixing plate 7 is used for fixing the first upper punch 8 and the second upper punch 10; like this The advantage is that the first upper punch 8 and the second upper punch 10 can be fixed by steps, which is convenient for replacement and maintenance of the first upper punch 8 and the second upper punch 10 . In this structure, the upper stripping plate 15 is fixed on the upper die punch fixing plate 7 through the upper spring 11 .

[0046] A lower die punch fixing plate 4 is also arranged between the lower stripping plate 5 and the lower die backing plate 3, and the lower die punc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com