Crank pin plug press mounting device

A press-fitting device and crank pin technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of poor operation accuracy and stability, bumping or scratching of crank pins, increasing labor intensity of staff and hidden dangers of operation safety, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The core of the present invention is to provide a crank pin plugging press-fitting device, which has high operation precision and a stable and efficient operation process.

[0023] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

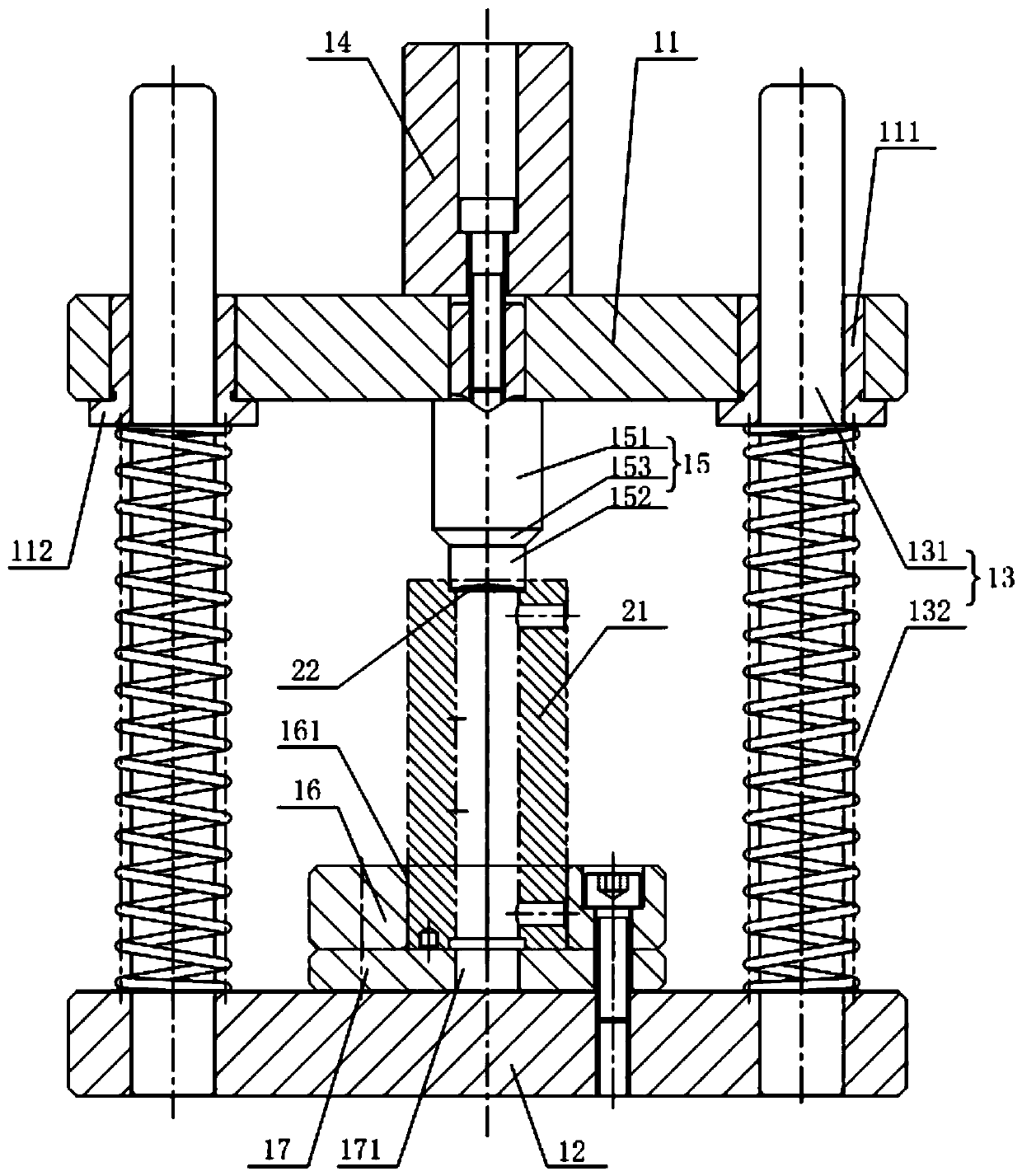

[0024] figure 1 It is a front view of the matching structure of the crank pin blockage press-fitting device provided by a specific embodiment of the present invention.

[0025] In a specific embodiment, the crank pin blockage press-fitting device provided by the present invention includes an upper die plate 11 and a lower die plate 12 arranged vertically in alignment from top to bottom, and also includes an upper die plate 11 connected vertically and the guide assembly 13 between the lower template 12; the top of the upper template 11 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com