Cold press for cold pressing and briquetting of foamed plastic

A foaming plastic and cold press technology, applied in the field of cold press, can solve the problems of low efficiency and slow speed, and achieve the effect of improving work efficiency and preventing jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

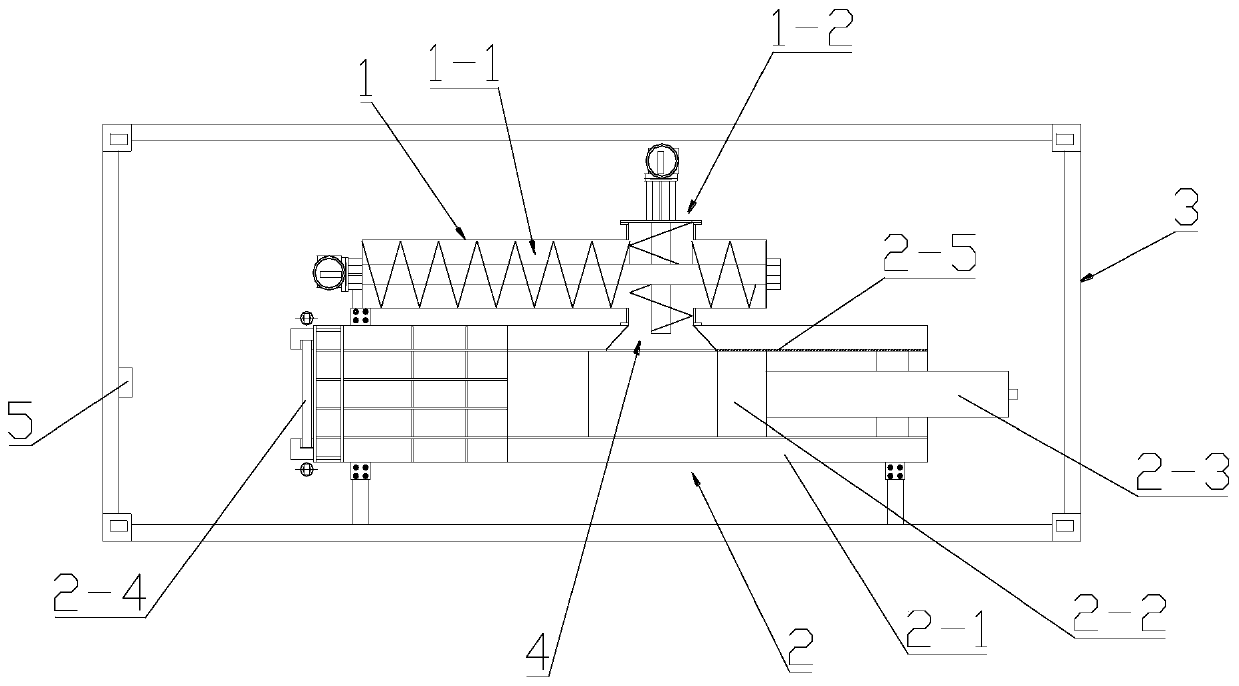

[0031] see Figure 1-Figure 4 , the present invention is used for the cold pressing machine that foamed plastics is carried out cold pressing briquetting comprises 3, is arranged on 3 and is used for conveying the feeding mechanism 1 of foamed plastics after crushing and is used for conveying to feeding mechanism 1 The cold-pressing briquetting mechanism 2 that the foamed plastic that comes over carries out cold-pressing.

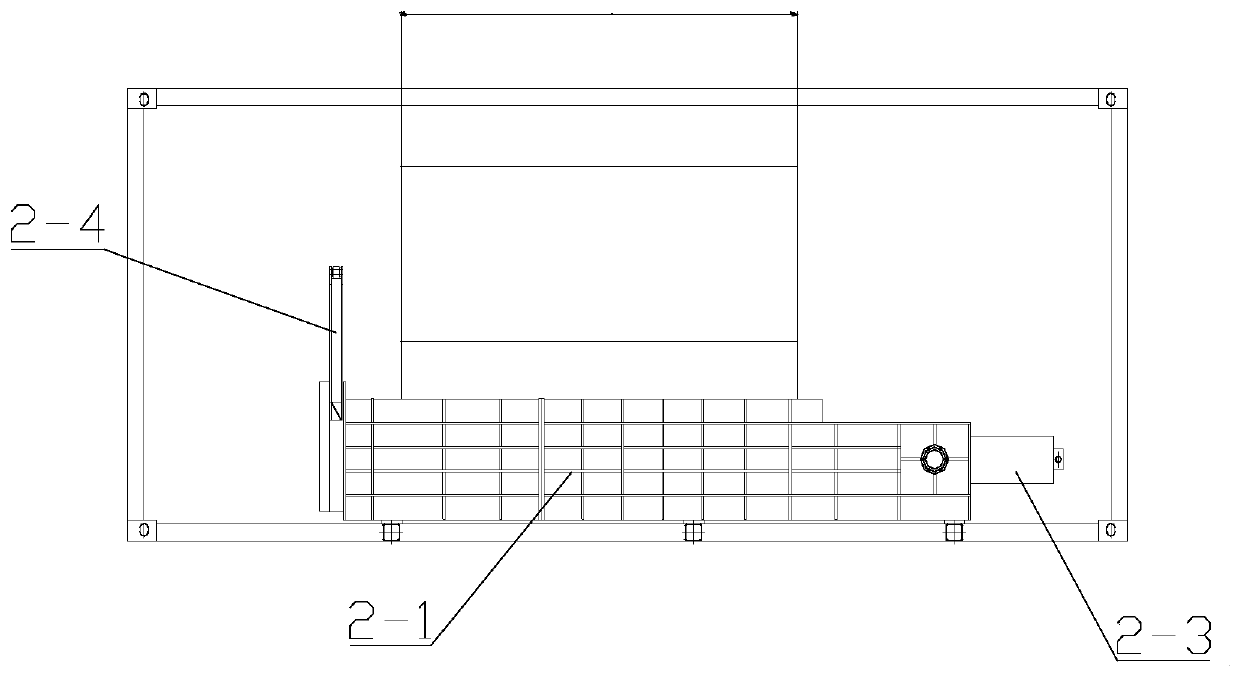

[0032] see Figure 1-Figure 4The cold pressing briquetting mechanism 2 includes a compression chamber 2-1, a pressure applying plate 2-2 arranged on the compression chamber 2-1, and a device for driving the pressure applying plate 2-2 to complete the cold pressing action. A pressure driving mechanism 2-3, wherein the compression chamber 2-1 is provided with a transition chamber 4 at a position corresponding to the feeding mechanism 1, and the transition chamber 4 is an inverted funnel shape, wherein the The end with a smaller diameter in the transition ch...

Embodiment 2

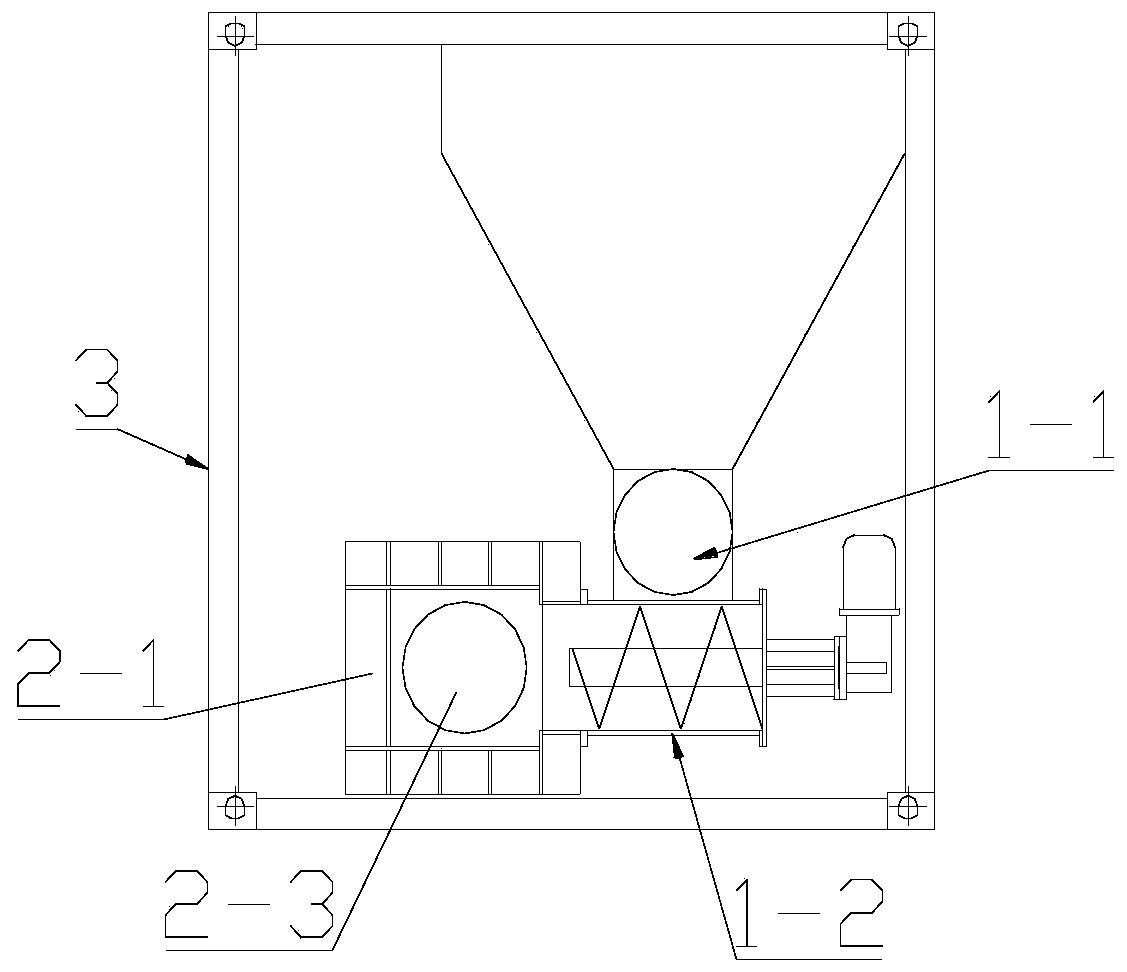

[0041] see Figure 5 and Figure 6 , the difference between this embodiment and Embodiment 1 is that: there are two groups of helical blades in the first helical pushing mechanism 1-1 above, and the rotation directions of the two groups of helical blades are opposite, and one group of helical blades is arranged at One side of the intersecting section of the first screw pushing mechanism 1-1 and the second screw pushing mechanism 1-2, and another group of helical blades are arranged on the other side of the intersecting section, between the two groups of helical blades The intersecting section of is the blanking space without helical blades. Through the above setting, it has the following advantages:

[0042] (1), be conducive to reasonable layout, reduce the volume of cold press machine of the present invention.

[0043] (2), since the feed port of the first screw pushing mechanism 1-1 is connected with the discharge port of the buffer transition bin, the second screw pushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com