A precise adjustment type small heat press machine using method

A heat transfer machine and adjustable technology, which is applied to general parts of printing machinery, printing presses, rotary printing presses, etc., can solve the problems of inability to infinitely adjust the transfer pressure and heating time, lack of portability, and heavy weight. Achieve the effect of improving portability, improving transfer stability, and high transfer quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

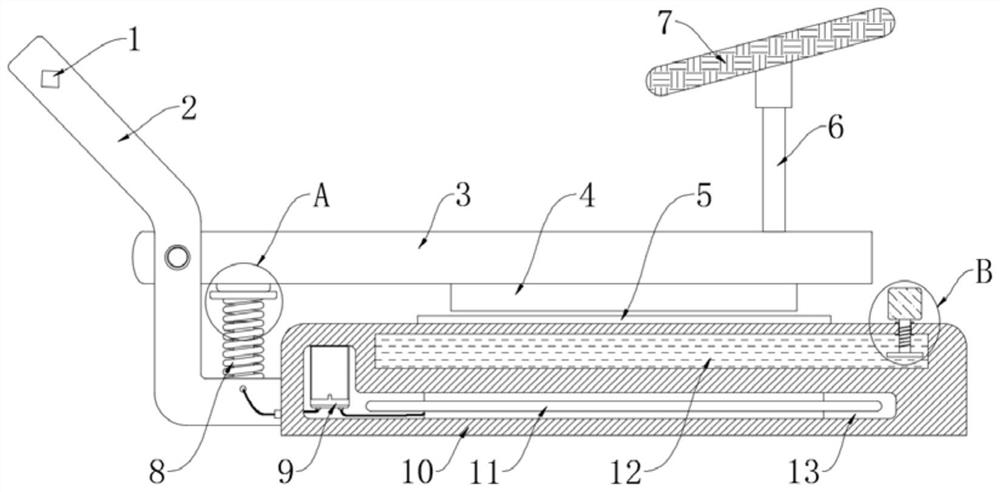

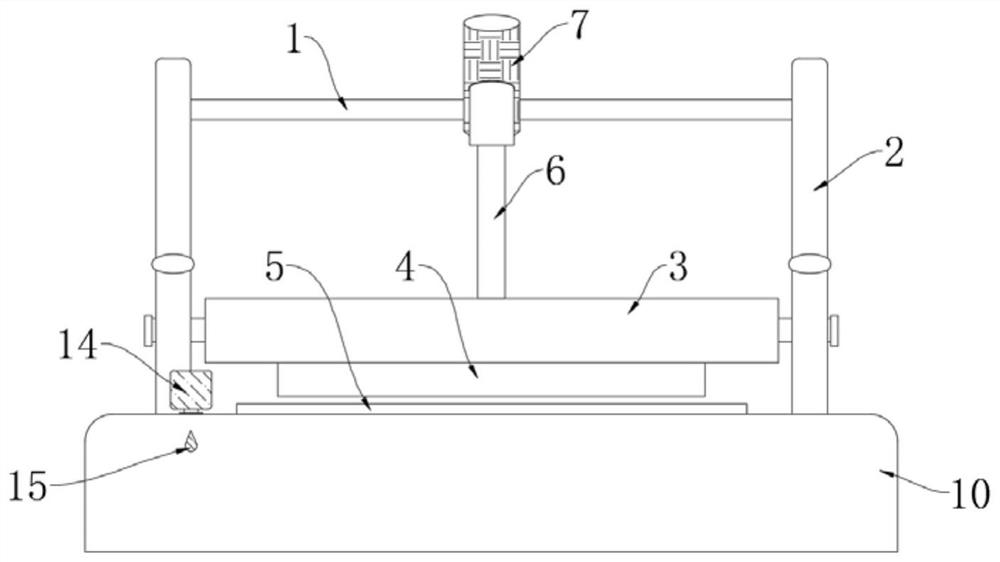

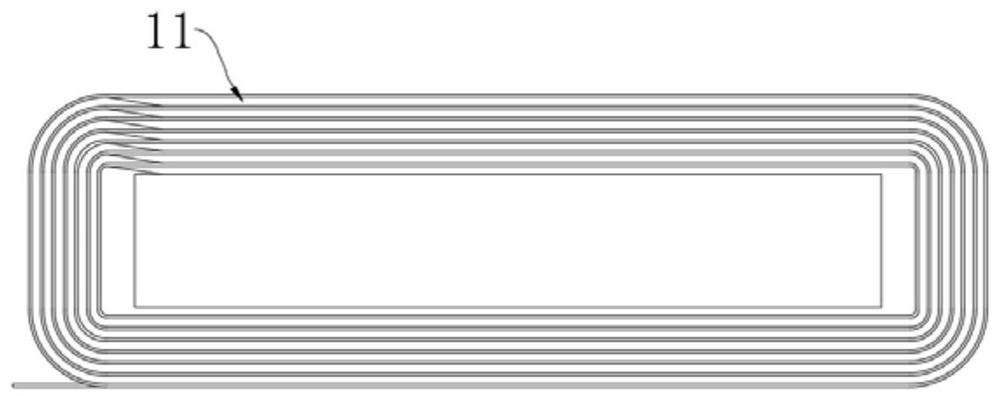

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0030] refer to Figure 1-5 , a method of using a precise adjustment type small heat press machine, the specific method of use is as follows:

[0031] S1. Preheating and detection: After turning on the power of the heat press machine and preheating for 10-20 minutes, observe whether the heating plate 4 is heating normally; estimate the transfer temperature and transfer time according to the material and color of the heat press, and set the parameters Adjust to the corresponding value, pull the handle 7 to turn the upper plate 3 to the horizontal bar 1, turn on the power of the heat press machine to preheat for 10-20 minutes, and observe whether the heating plate 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com