Volute assembly and air conditioner

An air conditioner and volute technology, applied in the field of air conditioning equipment, can solve the problems of air volume loss, easy deformation, large gap between two volutes, etc., and achieve the effect of ensuring the structural strength and ensuring the controllability of the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

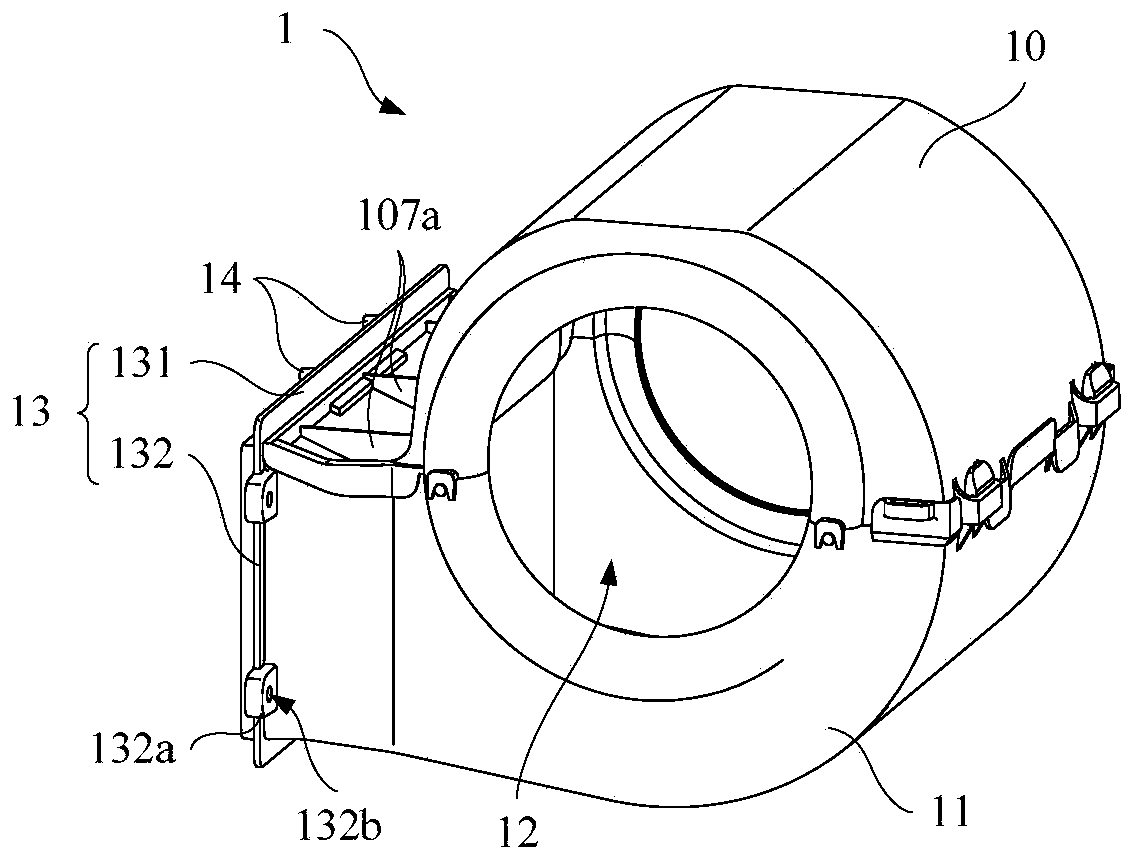

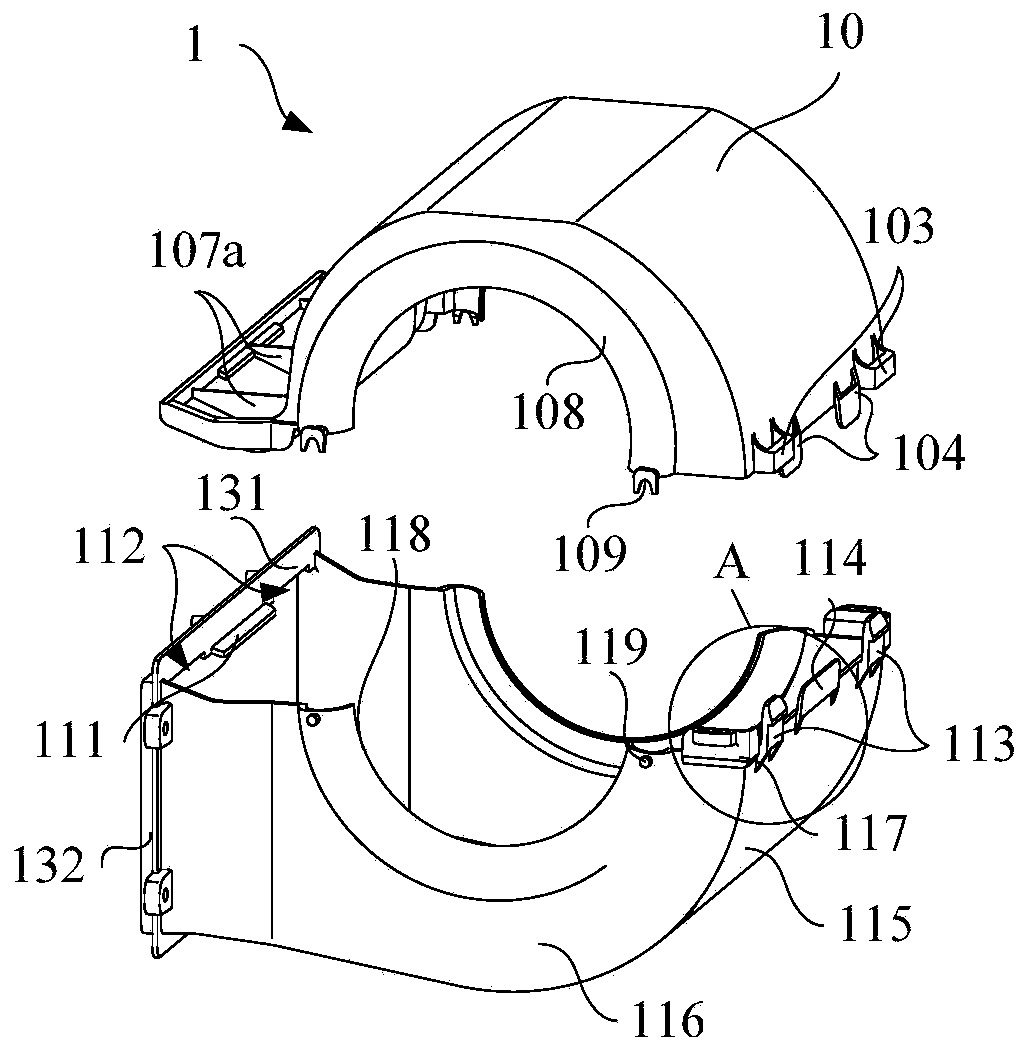

[0081] According to a first aspect of the present invention, a volute assembly 1 is provided, such as figure 1 , figure 2 and Figure 4 As shown, the volute assembly 1 includes a first volute 10, a second volute 11 and a reinforcing rib 13, wherein the second volute 11 and the first volute 10 are configured to form an air duct 12, and the air duct 12 has an air outlet 121 ; The reinforcing rib 13 is arranged on the end of the second volute 11 close to the air outlet 121 .

[0082] The volute assembly 1 provided by the present invention includes a first volute 10, a second volute 11 and a reinforcing rib 13, the first volute 10 is connected to the second volute 11, the first volute 10 and the second volute 11 can constitute an air duct 12, the air duct 12 is used to accommodate the fan of the air conditioner, the air duct 12 has an air inlet and an air outlet 121, and the reinforcing rib 13 is arranged on the end of the second volute 11 close to the air outlet 121. The pres...

Embodiment 2

[0096] Different from Embodiment 1, this embodiment further defines that the volute assembly 1 also includes positioning pins 14, such as Figure 4 and Figure 9 As shown, the positioning pin 14 is disposed on the side wall of the first reinforcing rib 131 away from the air duct 12 .

[0097] In this embodiment, the volute assembly 1 further includes a positioning pin 14, the positioning pin 14 is arranged on the side wall of the first reinforcing rib 131 away from the air duct 12, and the positioning pin 14 is used to connect the first volute 10 and the second volute The shell 11 is positioned and connected to the middle partition of the air conditioner, and the middle partition is provided with a positioning opening in advance, and the positioning pin 14 can pass through the positioning opening to realize the connection between the first volute 10, the second volute 11 and the middle partition. An installation opening is also provided on the middle partition, and the connec...

Embodiment 3

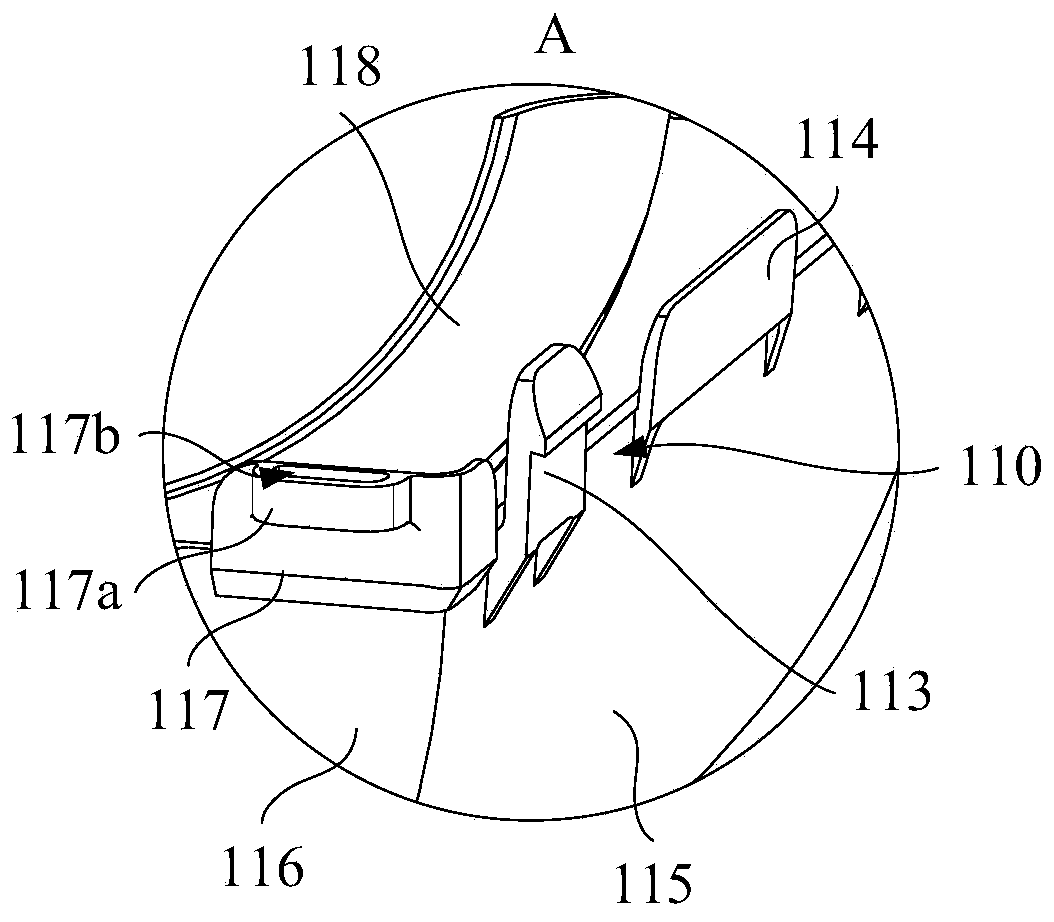

[0101] Different from the previous embodiments, this embodiment further defines that the volute assembly 1 further includes buckles 113 and hollow slots 103, such as image 3 and Figure 5 As shown, wherein, the buckle 113 is arranged on one of the first volute 10 and the second volute 11, and the buckle 113 is located at the end of the first volute 10 or the second volute 11 away from the air outlet 121; hollow The buckle 103 is disposed on the other of the first volute 10 and the second volute 11 corresponding to the buckle 113 , and the buckle 113 can pass through the hollow buckle 103 and be buckled on the groove wall of the hollow buckle 103 .

[0102] In this embodiment, the volute assembly 1 further includes a buckle 113 and a hollow groove 103, wherein the buckle 113 is arranged on one of the first volute 10 and the second volute 11, and the buckle 113 is located on the second volute 11. The end of the first volute 10 or the second volute 11 away from the air outlet 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com