High-vacuum vacuum valve driver

A technology for vacuum valves and drivers, applied to valve details, valve devices, engine components, etc., to achieve fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

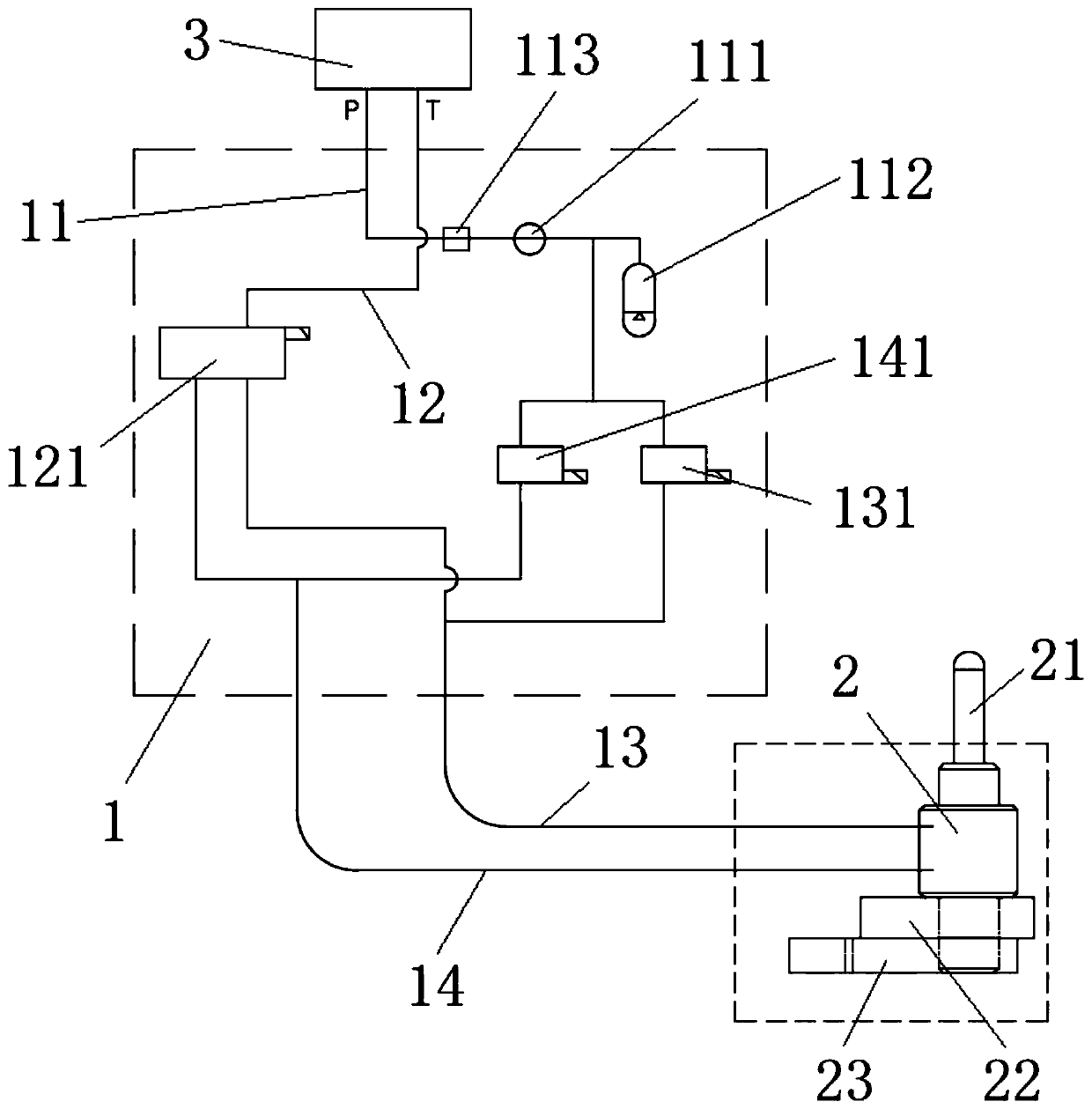

[0019] Such as figure 1 As shown, a high vacuum valve driver of the present invention includes an oil supply pipeline 1 for driving a vacuum valve core 21 capable of telescopic movement in the hydraulic cylinder 2, and the two chambers of the hydraulic cylinder 2 are respectively connected to open the oil circuit 13 and close the oil circuit 14. The oil supply pipeline 1 includes an oil delivery pipe 11 connected to the 3P port of the fuel tank and an oil return pipe 12 connected to the 3T port of the fuel tank. A first electromagnetic valve 131 is provided on the branch connected to the open oil circuit 13, and a second electromagnetic valve 141 is provided on the branch connected to the oil delivery pipe 11 to close the oil circuit 14. The open oil circuit 13 and the closed oil circuit 14 are respectively connected to a The electromagnetic reversing valve 121 on 12, the first electromagnetic valve 131, the second electromagnetic valve 141 and the electromagnetic reversing va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com