Auxiliary fixing device for railway annunciator

A railway signal machine and fixing device technology, which is applied in the direction of railway signal and safety, supporting machines, mechanical equipment, etc., can solve maintenance problems and achieve the effect of increasing the installation position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

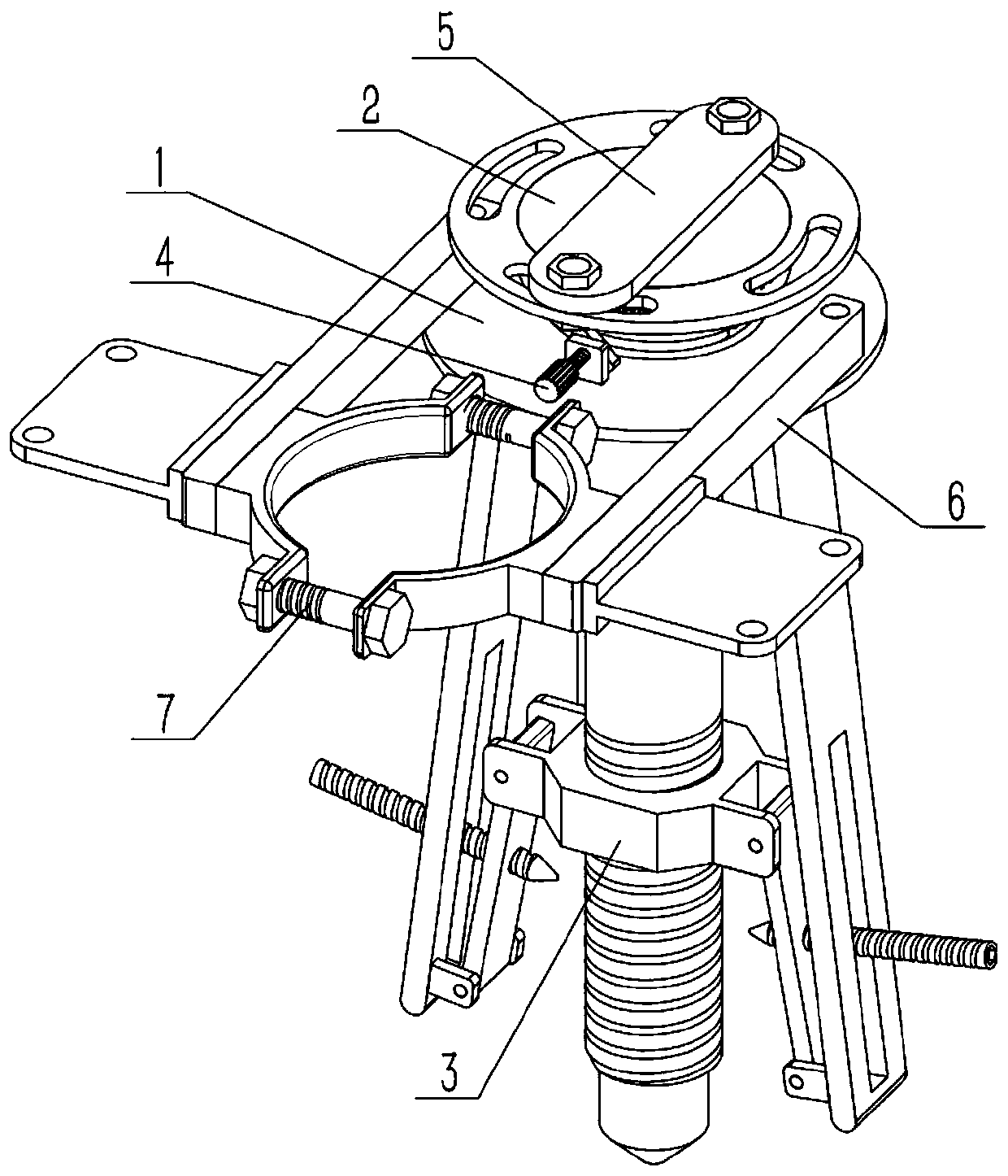

[0031] Such as Figure 1-10 As shown, an auxiliary fixing device for a railway signal machine includes a matching panel 2, a matching tube 201, a matching ring 203, a function port 204, a gear ring II 205, a nail plate 5, a nail rod 501 and a bolt and nut assembly I 502, and the matching panel The lower end of 2 is fixedly connected to and communicated with the matching pipe 201, and the matching ring 203 is fixedly connected to the outer ring end surface of the matching panel 2. The matching ring 203 is uniformly provided with a plurality of functional ports 204 in the circumferential direction, and the gear ring II 205 is fixed on the matching panel. 2, the matching tube 201 is located in the gear ring II 205, the lower end of the nail plate 5 is fixedly connected to the nail bar 501, and the nail bar 501 is slidably connected in the matching tube 201, and the lower end of the nail bar 501 is located below the lower end of the matching tube 201. The plate 5 is attached to th...

specific Embodiment approach 2

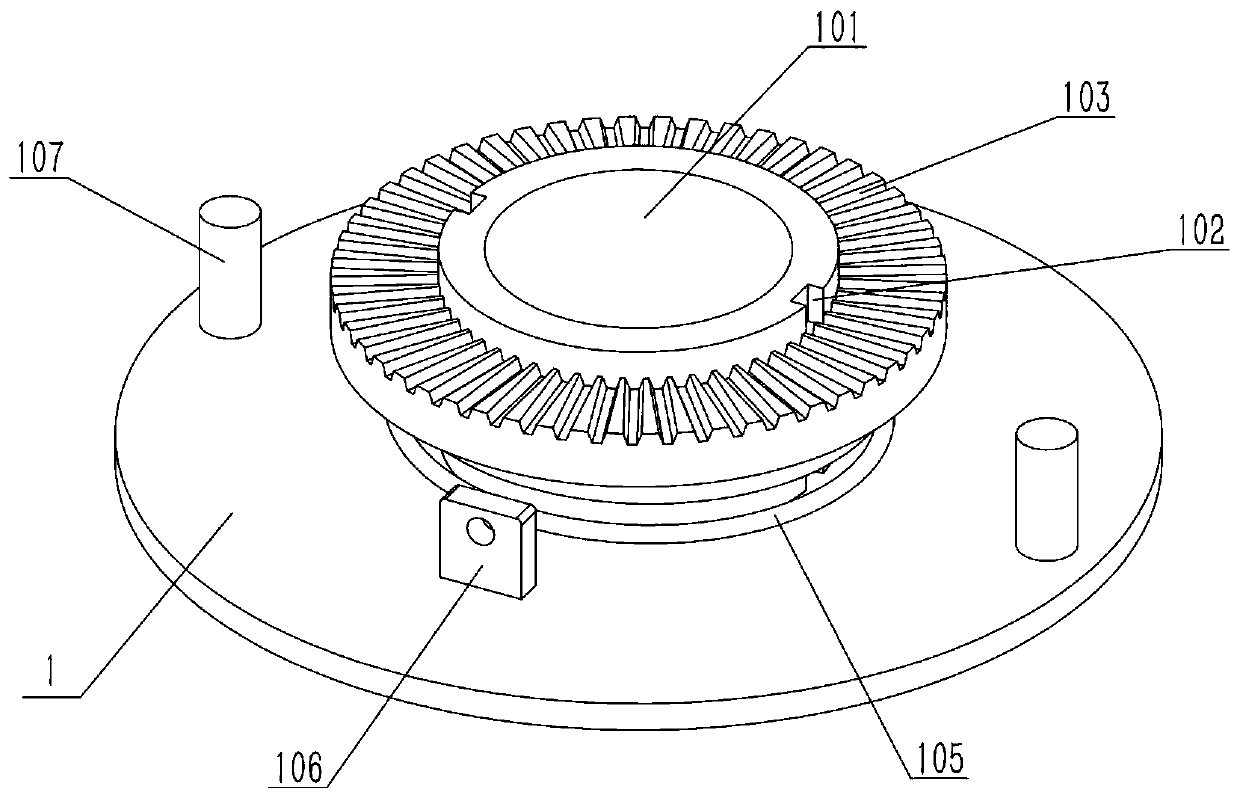

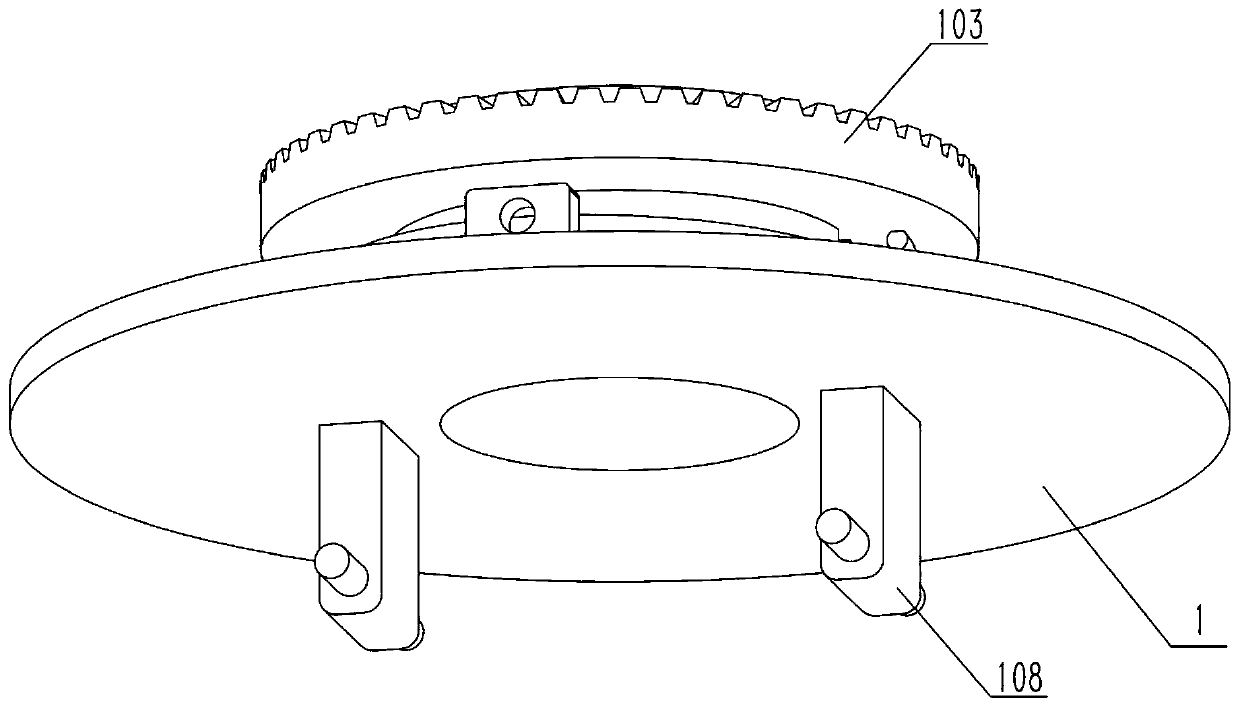

[0033] Such as Figure 1-10 As shown, the railway signal auxiliary fixing device also includes a basic panel 1, a basic pipe 101, a groove 102, a gear ring I 103, a convex part 104, a coil spring 105, a connecting part 108, an external thread 202, a central adjustment platform 3, a connecting Plate 301, connecting seat 302, counter plate 303 and connecting seat II 304, the upper end of the basic panel 1 is fixed and communicated with the basic pipe 101, the outer ring of the basic pipe 101 is provided with a groove 102, and the convex part 104 is fixed on the gear ring I103 , the gear ring I 103 is slidingly connected with the base pipe 101, the convex part 104 is slidingly connected in the groove 102, the coil spring 105 is sleeved on the base tube 101, and the upper and lower ends of the coil spring 105 are respectively in contact with the gear ring I 103 and the base panel 1, The left and right sides of the lower end of the basic panel 1 are fixedly connected with a connect...

specific Embodiment approach 3

[0035] Such as Figure 1-10 As shown, the auxiliary fixing device of the railway signal machine also includes a screw plate 106, a rod head 4, a screw II 401 and a pad 402. The screw plate 106 is fixed on the foundation panel 1, and the front end of the rod head 4 is fixed to the screw rod II 401. , the front end of the screw rod II 401 is fixedly connected to the cushion block 402 , the screw rod II 401 is threadedly connected to the screw plate 106 , and the cushion block 402 is located on the lower side of the gear ring I 103 . Rotate the rod head 4, the rod head 4 drives the screw rod II 401 to rotate, the screw rod II 401 drives the block 402 to rotate, make the block 402 vertical, and then use the block 402 to push the gear ring I103 up to keep the gear ring I103 and the gear ring II205 engaged, and then make the The matching tube 201 will not rotate when subjected to external force, and remains in a clamped state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com