A kind of processing method of high-grade alcohol anhydrous alcohol

An anhydrous alcohol, processing method technology, applied in chemical instruments and methods, sustainable manufacturing/processing, chemical industry and other directions, can solve the problems affecting the quality of anhydrous alcohol, not suitable for large-scale production, molecular sieve can not be loaded, etc. The effect of increasing utilization, reducing waste and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

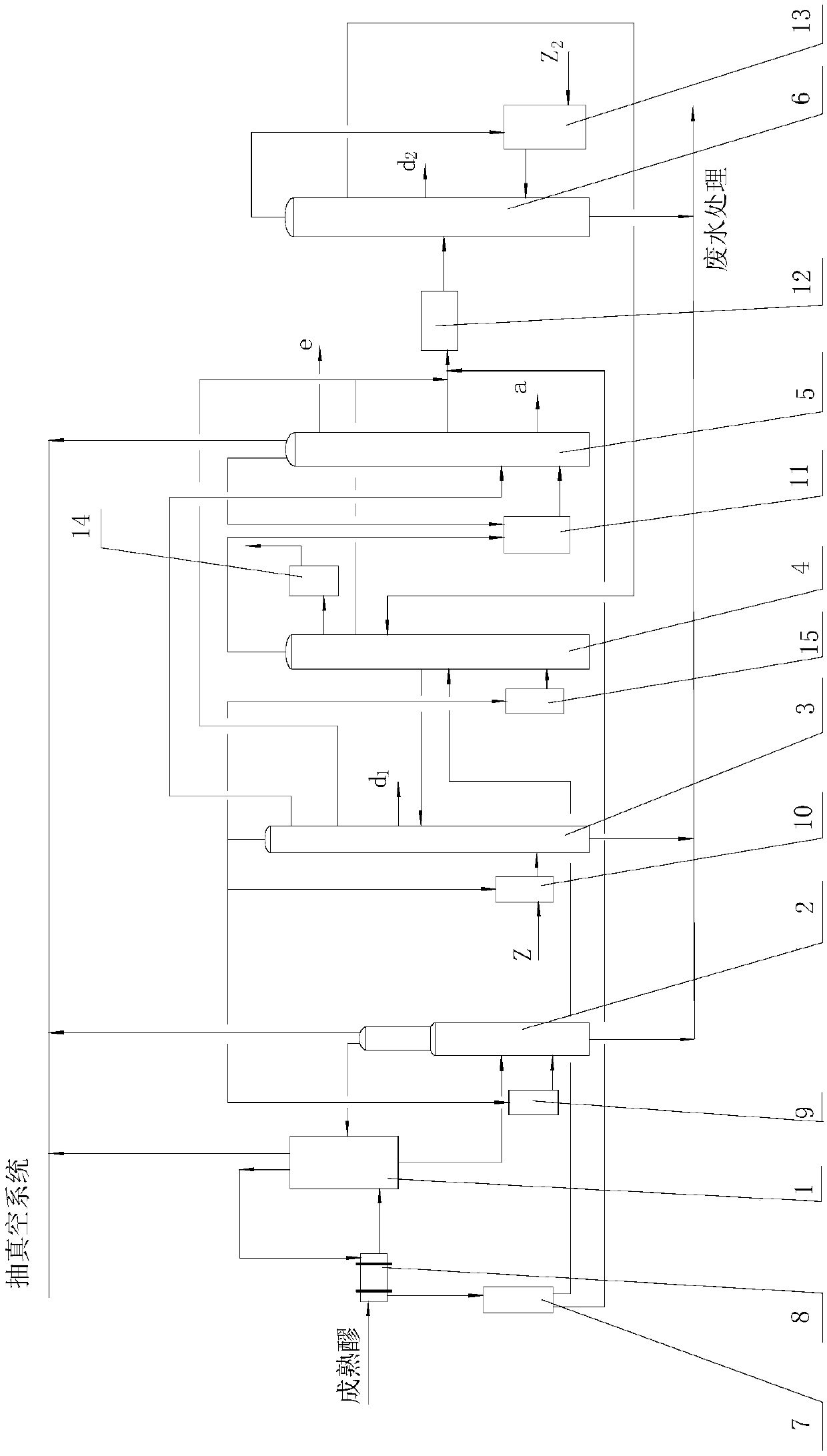

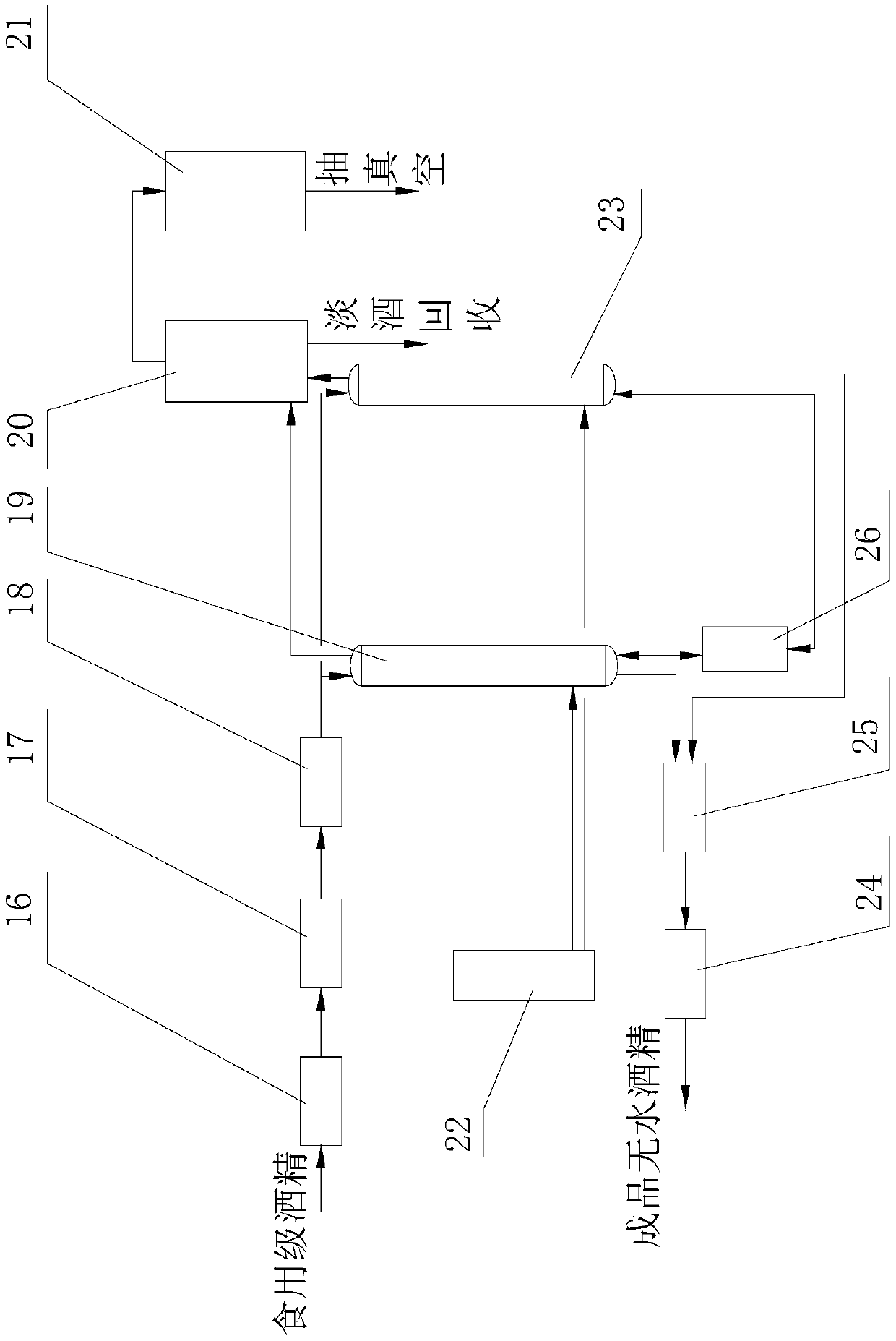

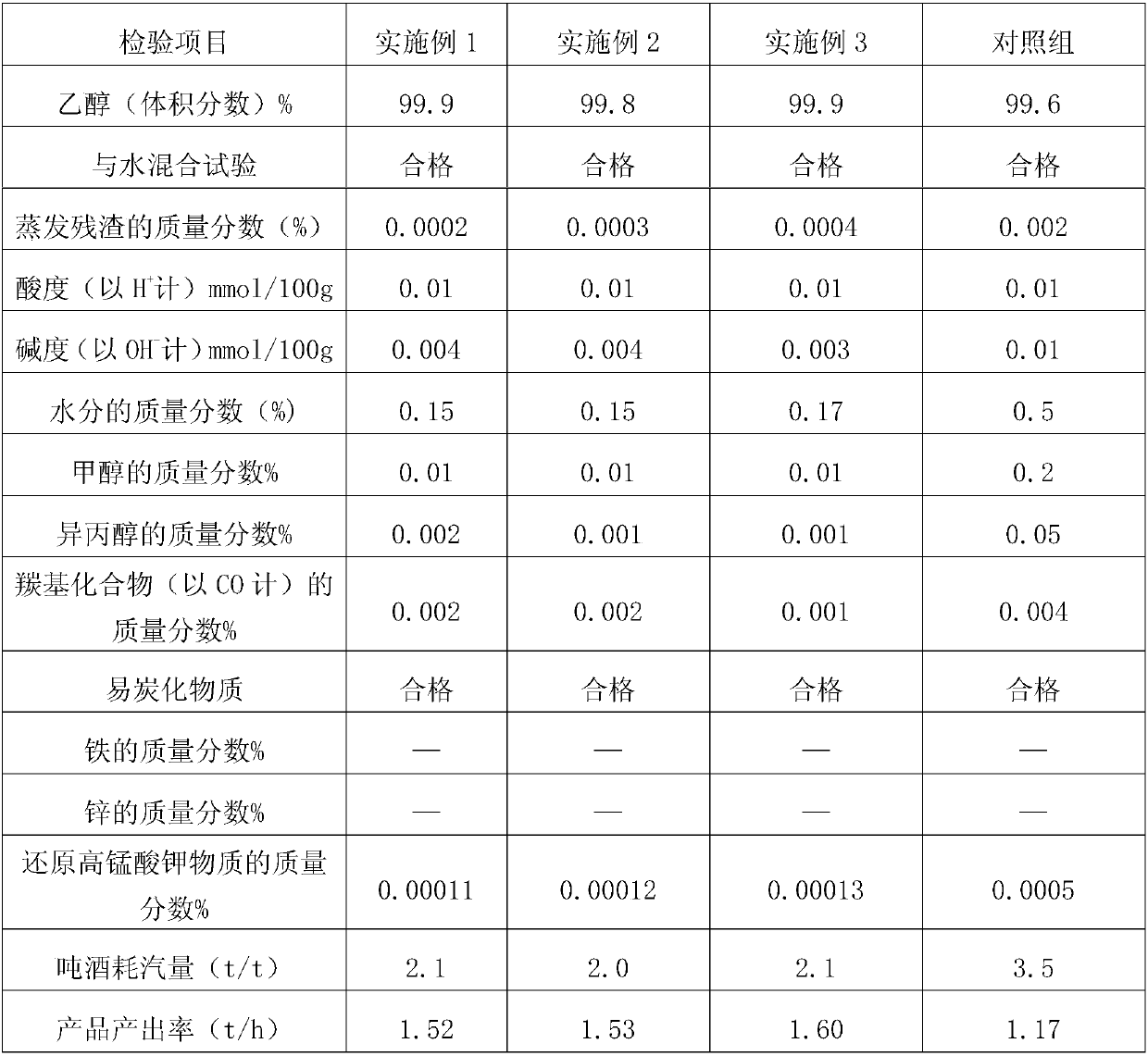

[0042]Pump the mature mash into the five-tower distillation system for distillation, and then pump the edible-grade alcohol collected from the methanol removal tower into the molecular sieve adsorption dehydration system for adsorption and dehydration. The edible-grade alcohol is preheated by the above-mentioned preheater and evaporated by the evaporator The heater is heated to form alcohol gas, which enters the molecular sieve for adsorption and then the absolute alcohol is collected in the condenser after the absolute ethanol. The light alcohol produced during the analysis process of the molecular sieve is recycled to the distillation recovery tower, and further distilled according to the steps of five-tower distillation, and finally from High-purity absolute ethanol with an alcohol content of 99.8%-99.9% (v / v) is collected by the absolute ethanol rear condenser.

[0043] In the above-mentioned five-tower distillation process, the gauge pressure at the bottom of the pre-fract...

Embodiment 2

[0045] Pump the mature mash into the five-tower distillation system for distillation, and then pump the edible-grade alcohol collected from the methanol removal tower into the molecular sieve adsorption dehydration system for adsorption and dehydration. The edible-grade alcohol is preheated by the above-mentioned preheater and evaporated by the evaporator The heater is heated to form alcohol gas, which enters the molecular sieve for adsorption and then the absolute alcohol is collected in the condenser after the absolute ethanol. The light alcohol produced during the analysis process of the molecular sieve is recycled to the distillation recovery tower, and further distilled according to the steps of five-tower distillation, and finally from High-purity absolute ethanol with an alcohol content of 99.8%-99.9% (v / v) is collected by the absolute ethanol rear condenser.

[0046] In the above-mentioned five-tower distillation process, the gauge pressure at the bottom of the prefract...

Embodiment 3

[0048] Pump the mature mash into the five-tower distillation system for distillation, and then pump the edible-grade alcohol collected from the methanol removal tower into the molecular sieve adsorption dehydration system for adsorption and dehydration. The edible-grade alcohol is preheated by the above-mentioned preheater and evaporated by the evaporator The heater is heated to form alcohol gas, which enters the molecular sieve for adsorption and then the absolute alcohol is collected in the condenser after the absolute ethanol. The light alcohol produced during the analysis process of the molecular sieve is recycled to the distillation recovery tower, and further distilled according to the steps of five-tower distillation, and finally from High-purity absolute ethanol with an alcohol content of 99.8%-99.9% (v / v) is collected by the absolute ethanol rear condenser.

[0049] In the above-mentioned five-tower distillation process, the gauge pressure at the bottom of the pre-frac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com