Cab frame structure for construction machine

A technology of frame structure and construction machinery, applied in the direction of building, superstructure, sub-assembly of superstructure, etc., can solve problems such as height restrictions, and achieve the effect of improving the installation position and expanding the viewing angle from above.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

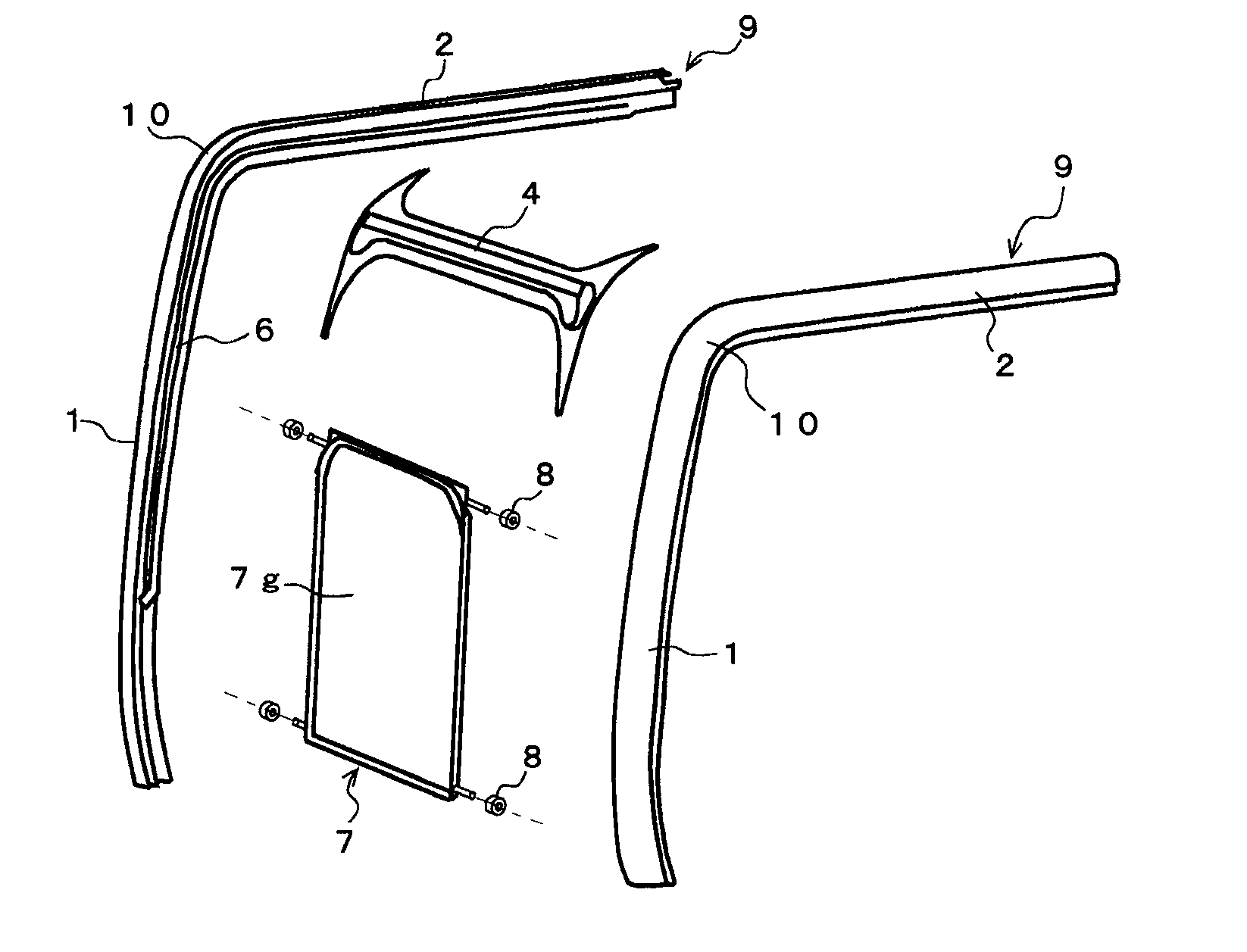

[0036] Preferred embodiments of the present invention will be described with reference to the drawings.

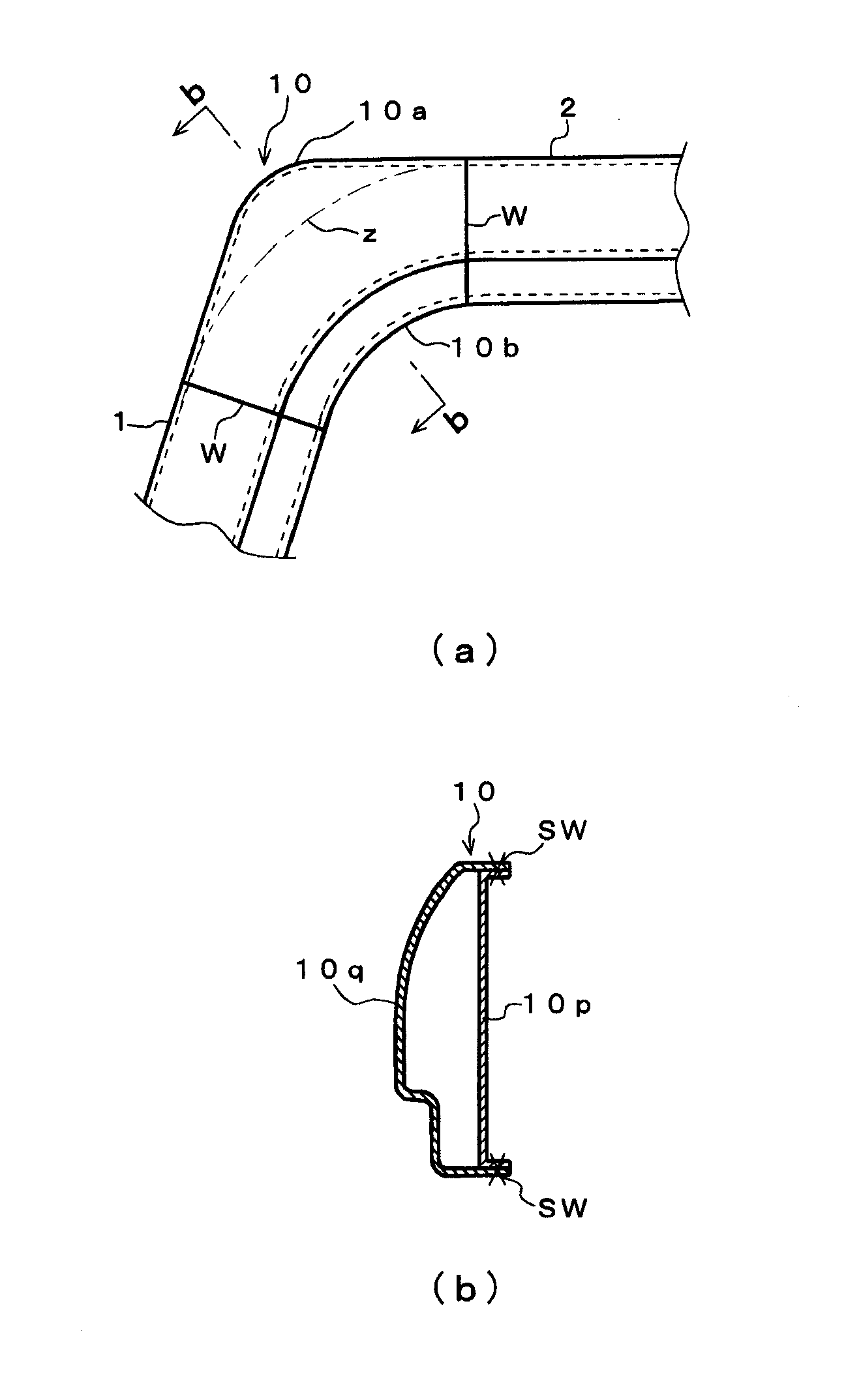

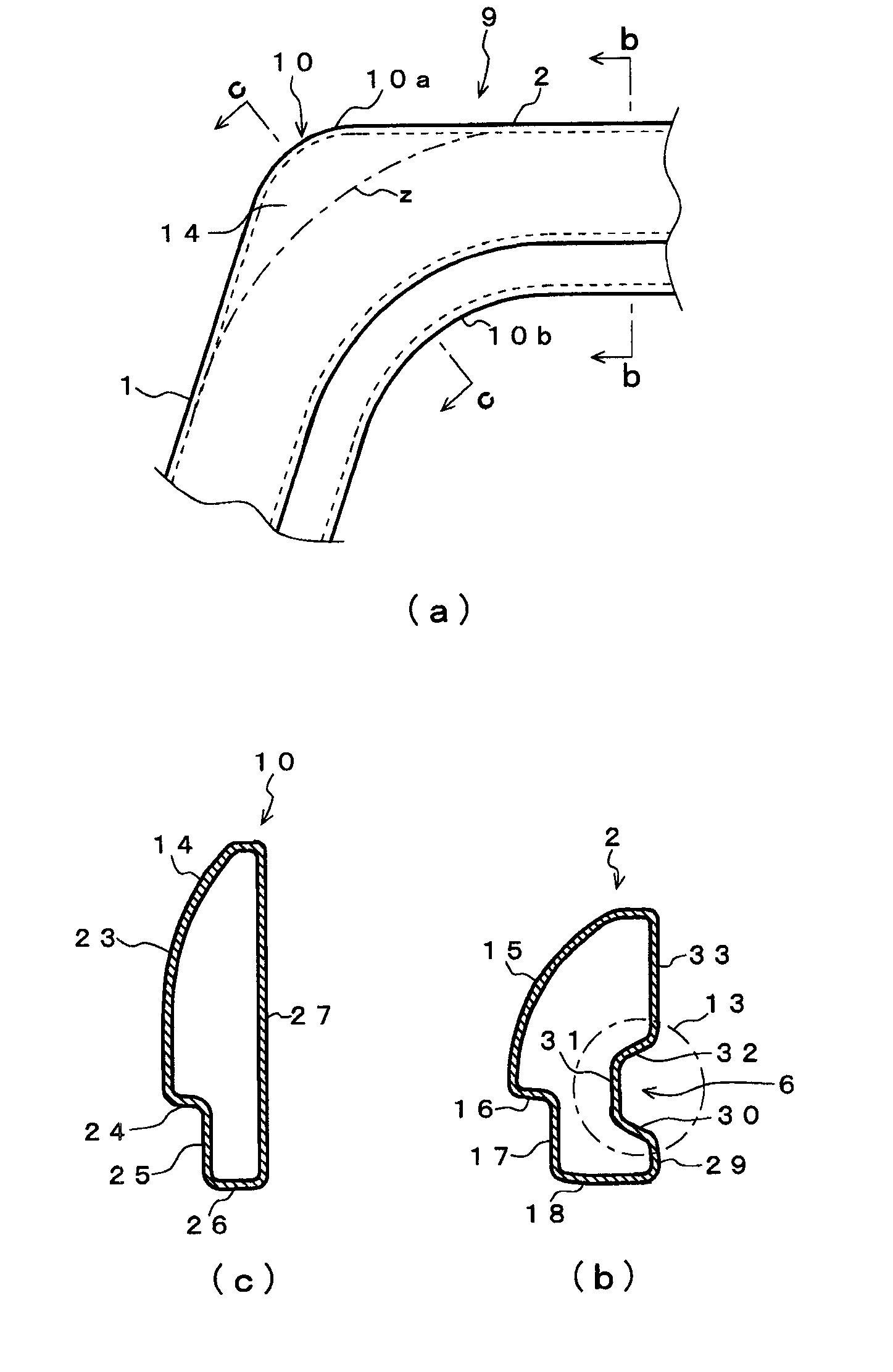

[0037] Such as Figure 5 As shown, the cab frame structure of the construction machine in this embodiment has and uses figure 1 and figure 2 With the same constituent elements as those already described, the front pillar 1 and the top pillar 2 constituting the frame of the cab are composed of a single pipe 9 having a bent portion 10 at the junction of these front pillars 1 and top pillar 2 . Therefore, the same components are denoted by the same reference numerals and their descriptions are omitted, and only the different points, that is, the features, will be described.

[0038] Such as Figure 5 As shown, the cab frame structure of the present embodiment is characterized in that the radius of curvature of the curved outer side 10a of the curved portion 10 of the pipe material 9 is smaller than the radius of curvature of the curved inner side 10b, thereby setting the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com