A tractor traction load moving test system and method

A technology of traction load and mobile testing, which is applied in the field of tractor testing, can solve problems such as poor stability, waste of power, and unrealistic testing, and achieve the effects of good testing stability, widening usage scenarios, and widening testing functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

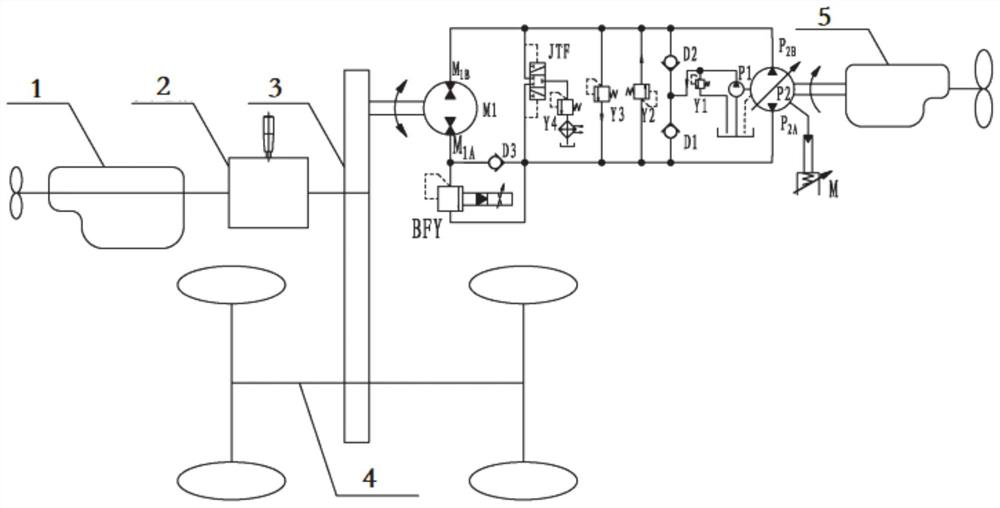

[0028] In a typical embodiment of the present invention, such as figure 1 As shown, a tractor traction load moving test system includes a transfer case 3, a hydraulic motor 6, a hydraulic control mechanism and a hydraulic power source. The hydraulic motor 6 is connected to the hydraulic control mechanism, and the hydraulic control mechanism is connected to the hydraulic power source. The hydraulic control mechanism can The rotation of the hydraulic motor 6 is controlled. The output end of the hydraulic motor 6 is connected to the transfer case 3. The transfer case 3 is used to communicate with the running system of the load vehicle. The transfer case 3 can also be used to communicate with the gearbox 2 of the load vehicle.

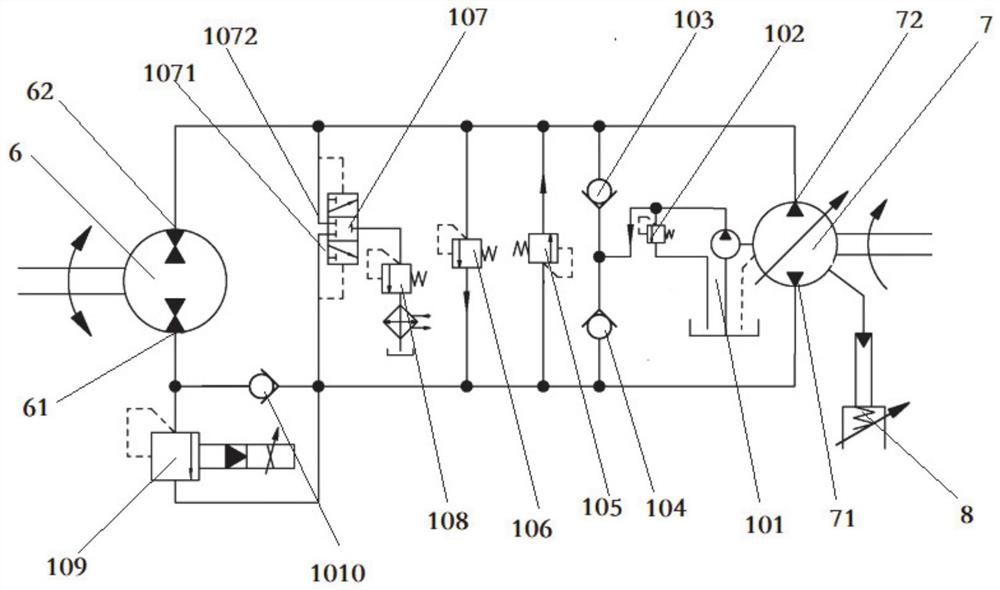

[0029] The hydraulic power source in this embodiment includes a variable displacement pump 7 and a second engine 5 communicating with and driving the variable displacement pump 7; the variable displacement pump 7 has two inlets and outlets.

[0030] Please...

Embodiment 2

[0047] In a typical implementation of the present invention, a kind of tractor traction load moving test method is also provided, when driving normally, the power system of the original vehicle of the load is used; during the loading test, the power system of the original vehicle is disconnected, Access and use a tractor-drawn load moving test system as described in Example 1.

[0048] Specifically, such as figure 1 As shown, in this embodiment, the load truck includes a load truck engine 1, a gearbox 2 and a walking system 4, the output end of the load truck engine 1 is connected to the gearbox 2, the gearbox 2 is connected to the transfer case 3, and the transfer case 3 is connected to the walking system Department 4.

[0049] It can be understood that the transfer case 3 is a commonly used mechanical device at present, which is a device for distributing the power of the engine 5, and can output the power to the rear axle, or to the front / rear axle at the same time, otherwi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com